Disposable waste gas adsorption device, system and use method

An adsorption device, one-off technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of single, small system emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

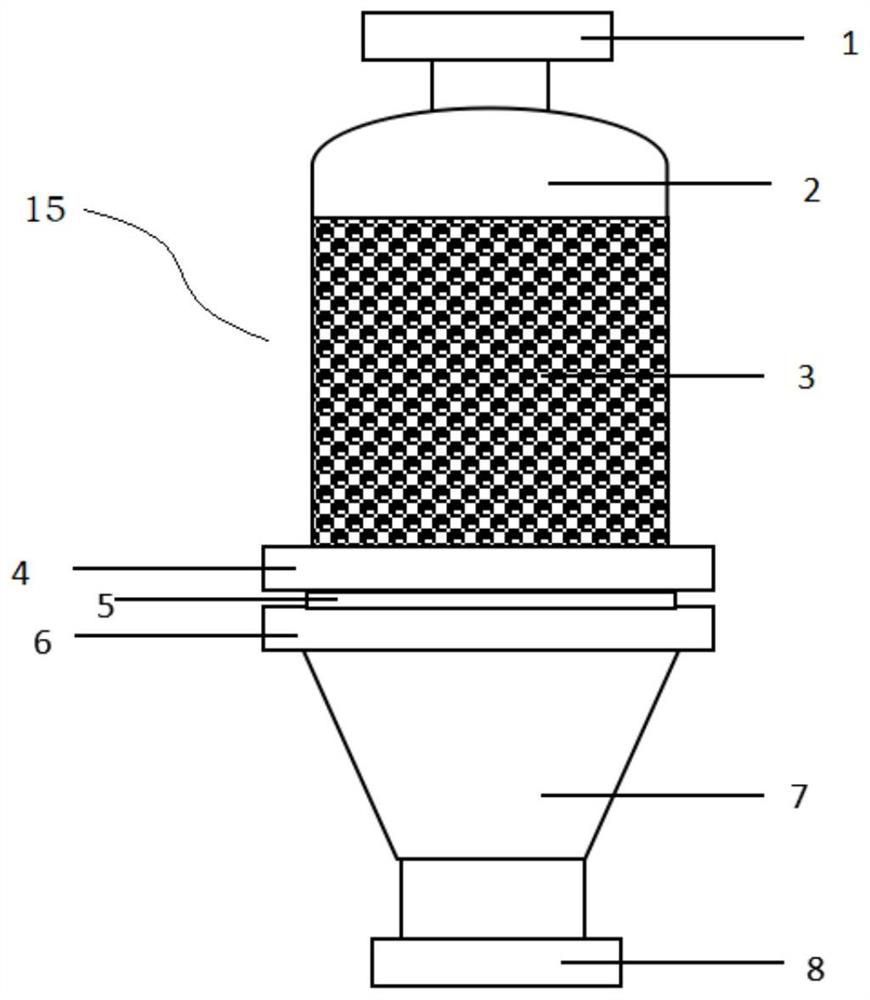

[0031] Such as Figure 1-2 As shown, a disposable waste gas adsorption device 15 of this embodiment includes a cylinder body 2, a first opening is provided on the top end of the cylinder body 2, and a first flange 1 is provided on the first opening; an end cover 7 is also included, The end cover 7 is an inverted truncated cone, the top opening of the end cover 7 is provided with a second flange 6, the bottom opening of the cylinder 2 is provided with a third flange 4, and the end cover 7 passes through the second flange 6 and the second flange 6. The three flanges 4 are hermetically connected to the cylinder, a sealing gasket 5 is provided between the second flange 6 and the third flange 4 and connected by bolts, the bottom end of the end cover 7 is provided with a second opening, and the second opening There is a fourth flange 8 on the top; a filter 3 is provided in the cylinder body 2, and the filter 3 is filled with an adsorption filter material; the adsorption filter mater...

Embodiment 2

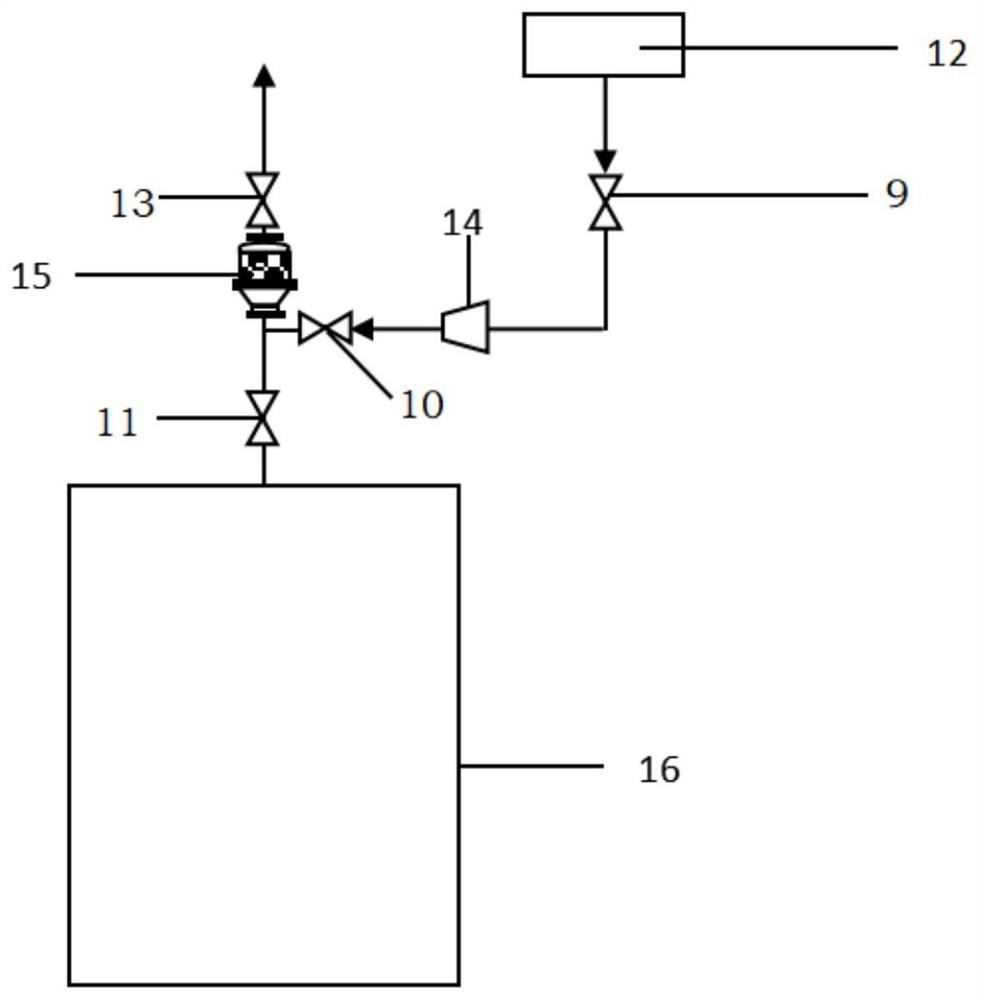

[0034] The system of this embodiment is equipped with the disposable waste gas adsorption device in Embodiment 1, including a container 16 for storing harmful substances. The container 16 is provided with a waste gas pipeline, and the waste gas pipeline is used to discharge the waste gas in the container 16. The disposable waste gas adsorption device 15 is installed on the waste gas pipeline through the first flange 1 and the fourth flange 8, wherein the first flange 1 is arranged downstream of the fourth flange 8; Tank breathing system switch valve 11 and waste gas outlet switch valve 13, and a VOC detector is installed on the waste gas pipeline downstream of the disposable waste gas adsorption device 15;

[0035] It also includes a nitrogen blanketing pipeline, the inlet of the nitrogen blanketing pipeline is connected to the nitrogen device 12, and the outlet of the nitrogen blanketing pipeline is connected to the upstream of the disposable exhaust gas adsorption device 15 a...

Embodiment 3

[0037] The system in this embodiment has the same structure as the system in Embodiment 2 except for the following structure.

[0038] The disposable waste gas adsorption device 15 is installed on the waste gas pipeline through the first flange 1 and the fourth flange 8 , wherein the first flange 1 is arranged upstream of the fourth flange 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com