Multi-junction solar cell

A technology of solar cells and sub-cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as voltage loss, and achieve the effect of high lateral conductivity and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

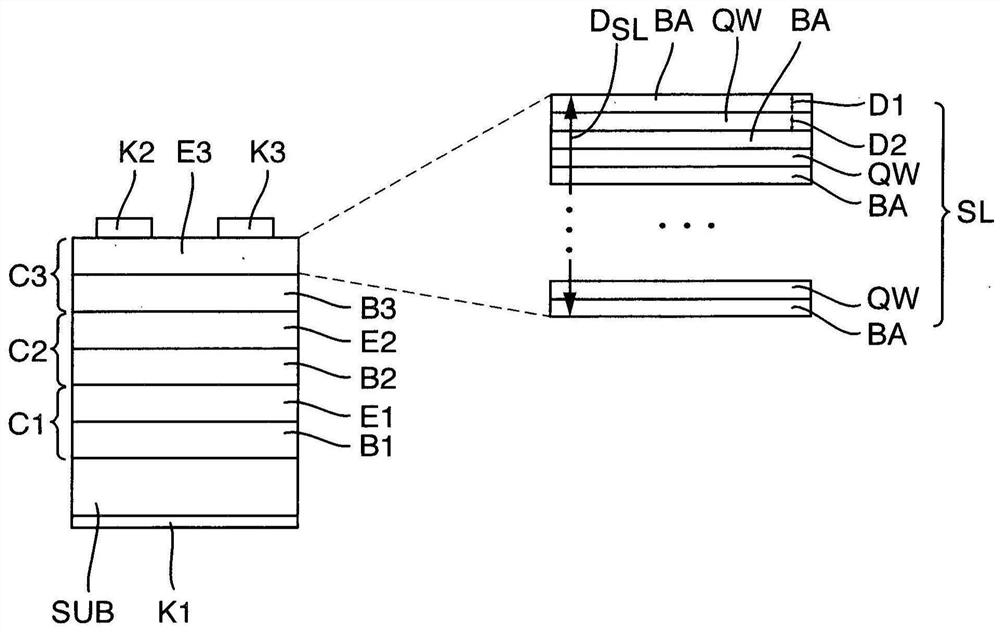

[0056] figure 1 The image in shows a view of a first embodiment of a stacked multi-junction solar cell MJ comprising a stack consisting of a substrate layer SUB, a lowermost subcell C1, a middle subcell C2 and an uppermost subcell C3 ST. A flat connection layer K1 is formed on the underside of the stack ST. Connecting fingers K2 , K3 are arranged on the upper side of the stack.

[0057] Each sub-cell C1, C2, and C3 has a base B1, B2, B3 and an emitter E1, E2, E3, respectively, wherein the emitter E3 and the base B3 of the uppermost sub-cell C3 are made of III-V semiconductor materials composition.

[0058] The emitter E3 of the uppermost sub-cell C3 comprises a superlattice SL. The superlattice includes a plurality of thin well layers QW with a thickness of D2 and a plurality of thin barrier layers BA with a thickness of D1, wherein the well layers QW and the barrier layers BA are alternately stacked on each other. The total thickness D of the superlattice SL From the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com