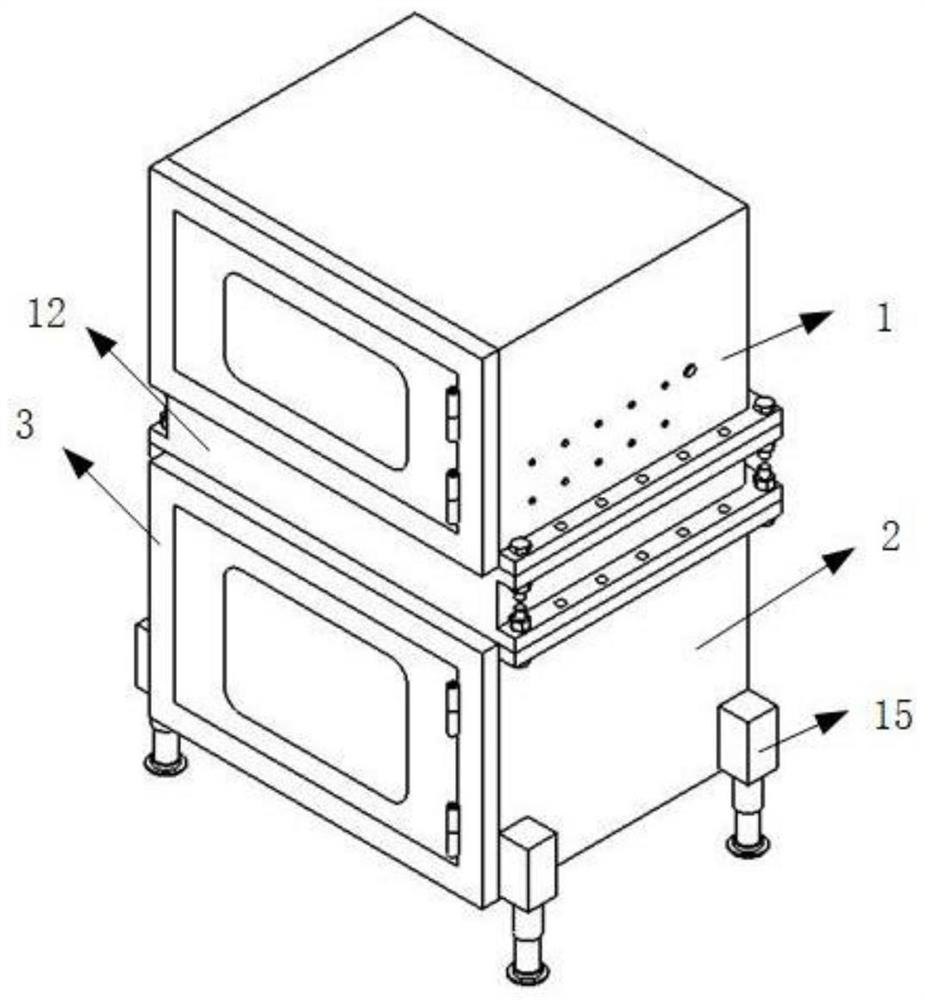

Composite material vibration and noise reduction tester and method based on reverberation plane acoustic wave excitation

A planar acoustic wave, vibration reduction and noise reduction technology, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, material analysis, and use of sound waves/ultrasonic waves/infrasonic waves to analyze solids. Application of engineering site and other issues to achieve the effect of reducing costs and testing indicators comprehensively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

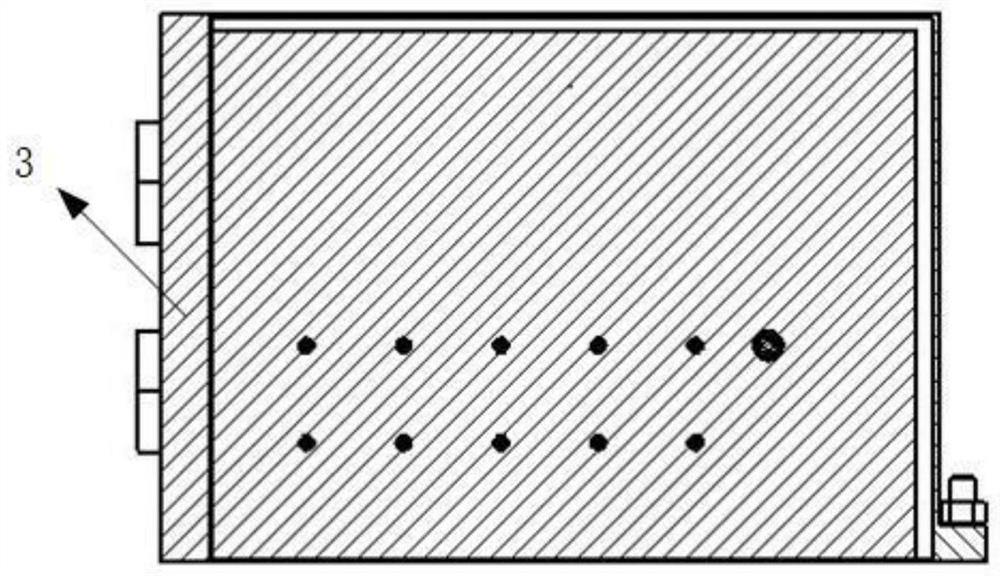

[0064] Example: Intrinsic characteristics and vibration response tests of composite thin plates excited by planar acoustic pulses.

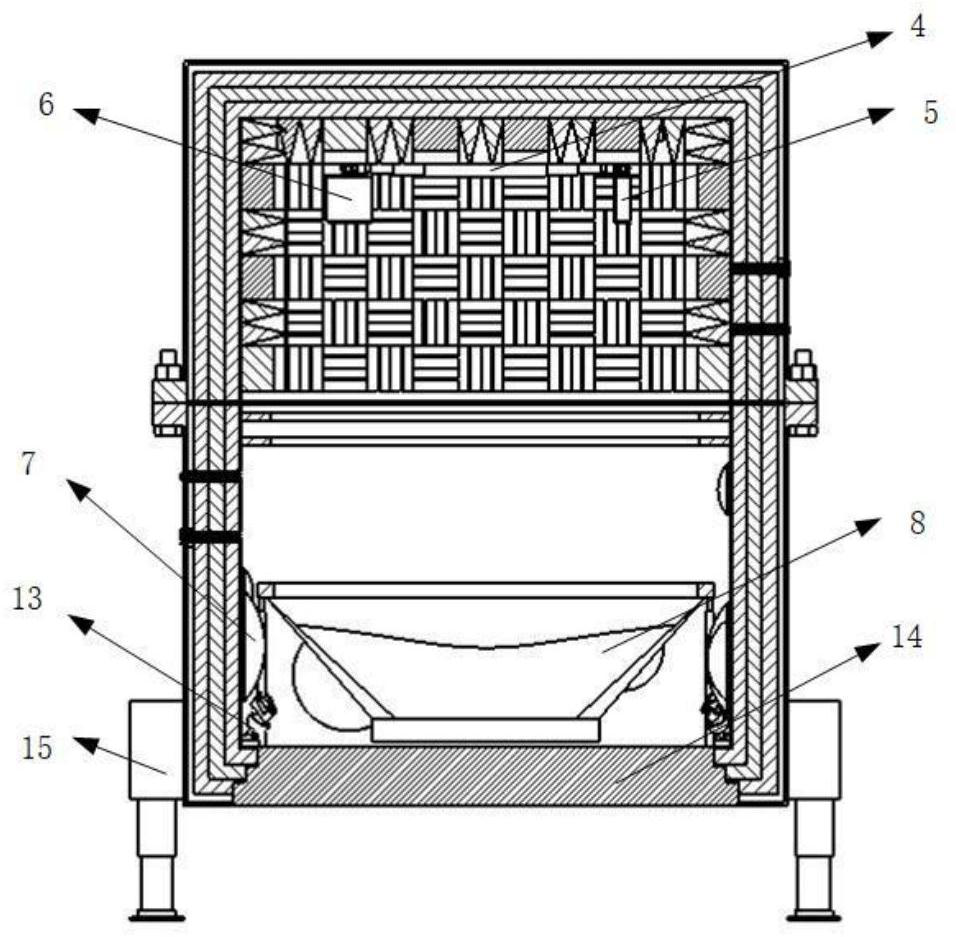

[0065] The reverberation box used is the box body designed by this patent. The test sample is a CF140 carbon fiber / epoxy resin composite sheet, and its intrinsic characteristics and response to planar pulse acoustic excitation are studied. This type of sheet is laid symmetrically and orthogonally, that is, [(0° / 90°) 5 / 0° / (90° / 0°) 5 ], a total of 11 layers, each layer has the same thickness and fiber volume fraction, density ρ=1778kg / m 3 , The length, width and thickness are 400×400×1.24mm.

[0066] (1) Connecting equipment: install the test piece into the frame-shaped clamping plate fixture and tighten the bolts to fix it, open the second signal output channel of the data acquisition instrument, adjust the excitation frequency of the random excitation signal, connect the pre-power amplifier, the pure rear The first-class power amplifier and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com