Walking trolley equipment for searching optical cable surface biting wound

A traveling trolley and optical cable technology, applied in the field of communication, can solve the problems of optical cable damage, difficult sliding operation, delay in repair time and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

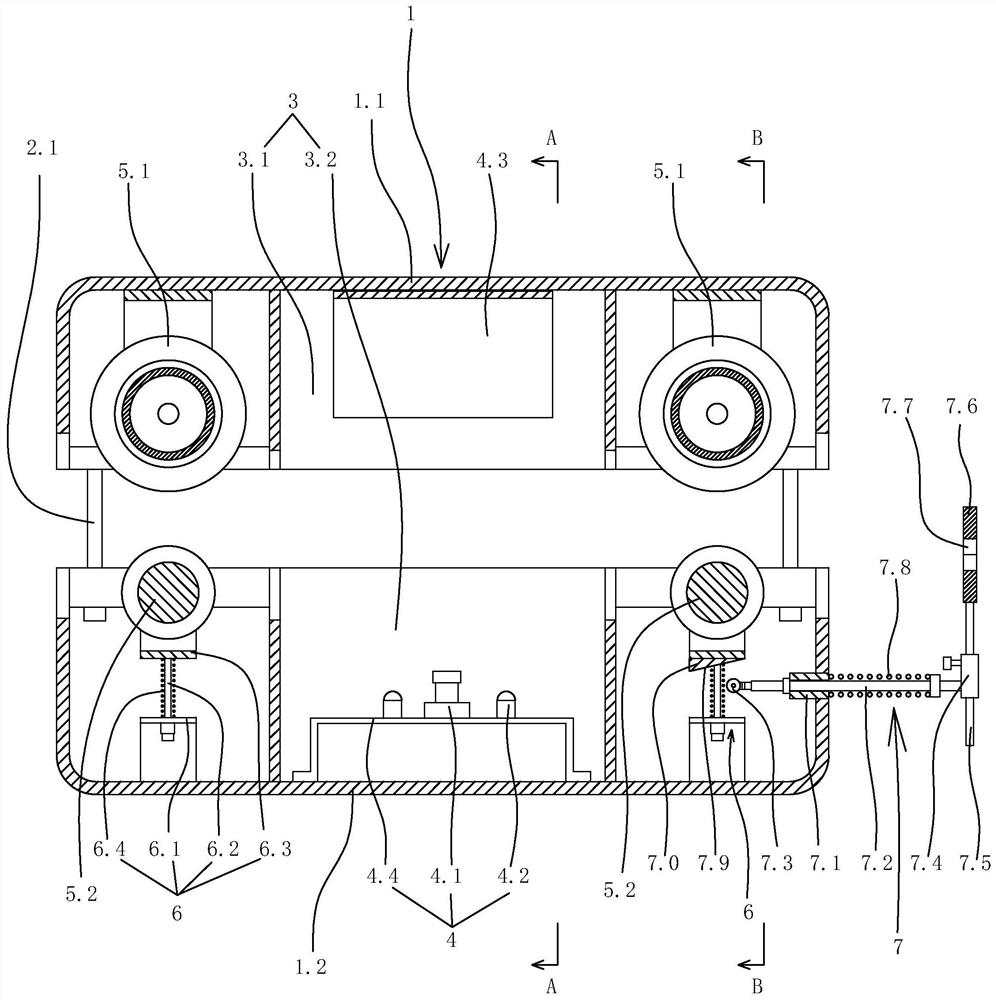

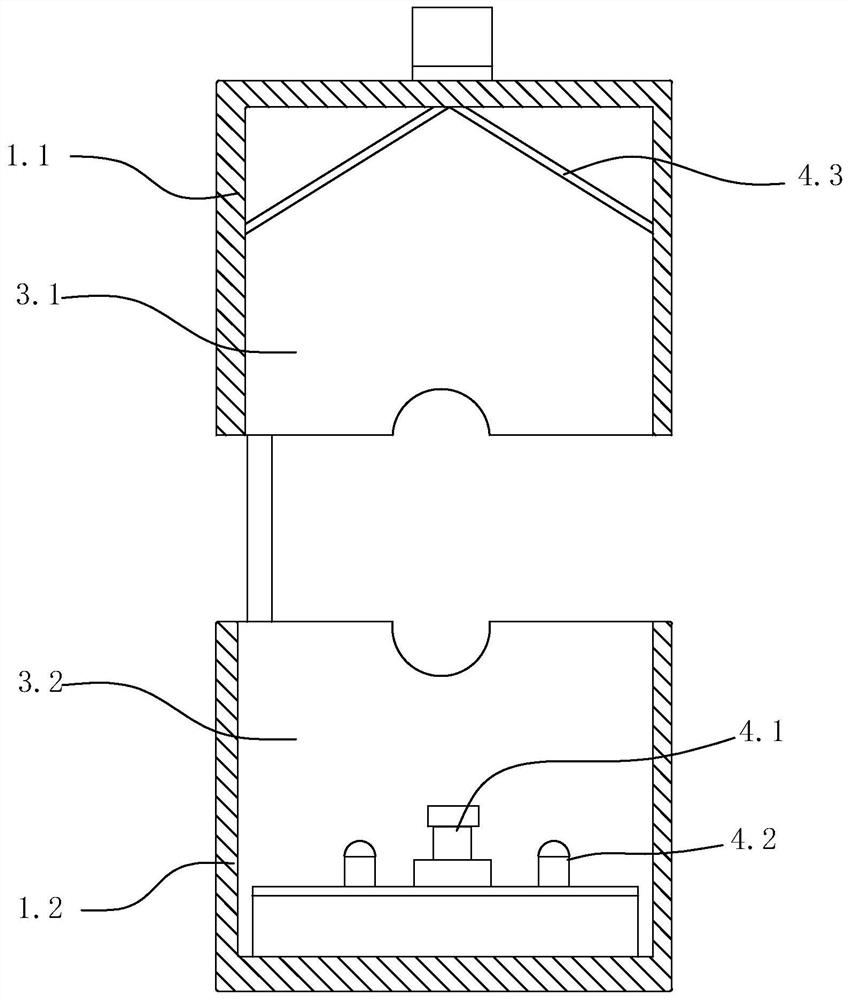

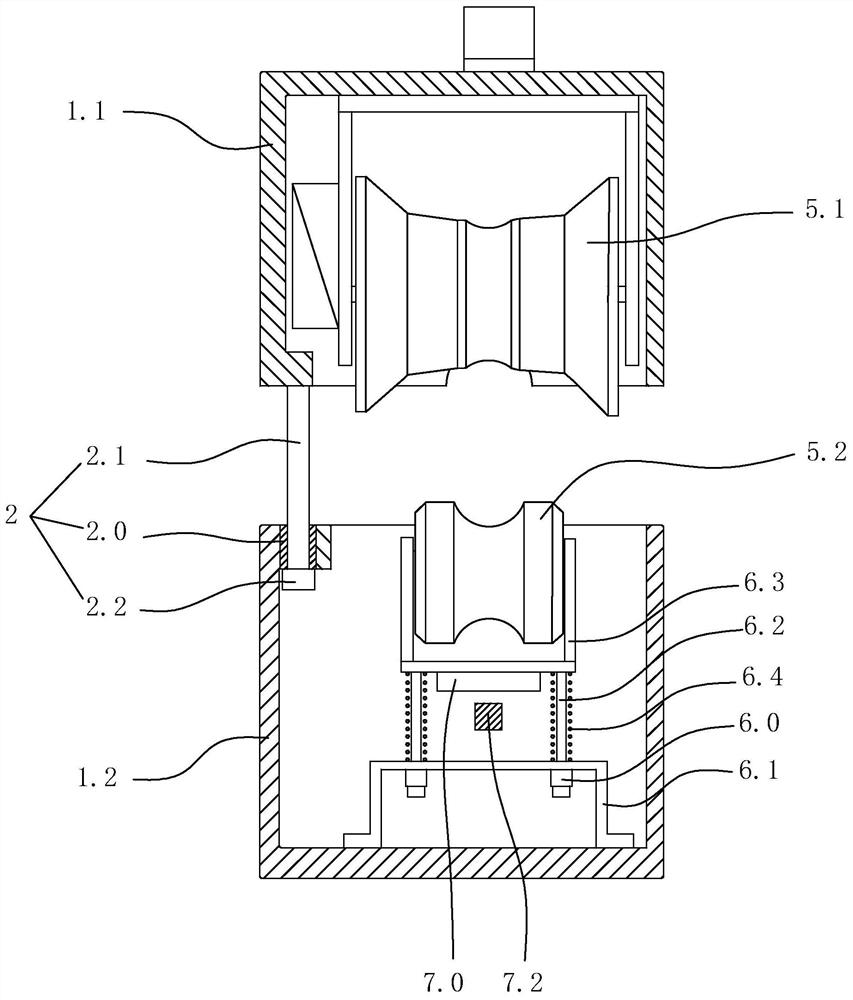

[0041] Specific embodiment one: as figure 1 , figure 2 , Figure 5 As shown, a walking trolley device for finding gnawing wounds on the surface of an optical cable includes a walking trolley, a detection darkroom 3 and a gnawing wound detection device 4 . The walking trolley is suspended on the ADSS optical cable 8 and can walk along the ADSS optical cable. A closed cavity is arranged inside the walking trolley, and the cavity constitutes a detection chamber 3 through which the ADSS optical cable passes. The gnawing wound detection device includes a 365nm ultraviolet lamp 4.2 and a camera 4.1 arranged in the detection darkroom, and the camera is used to photograph the ADSS optical cable located in the detection darkroom. The gnawing wound refers to the gnawing wound left by small animals such as squirrels when gnawing on the optical cable.

[0042] The gnawing wounds left by small animals such as squirrels when they gnaw on optical cables are generally relatively small, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com