An energy-saving and environment-friendly waste incineration system

A waste incineration, energy saving and environmental protection technology, applied in the direction of incinerator, combustion type, combustion method, etc., can solve the problem of energy waste in waste incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

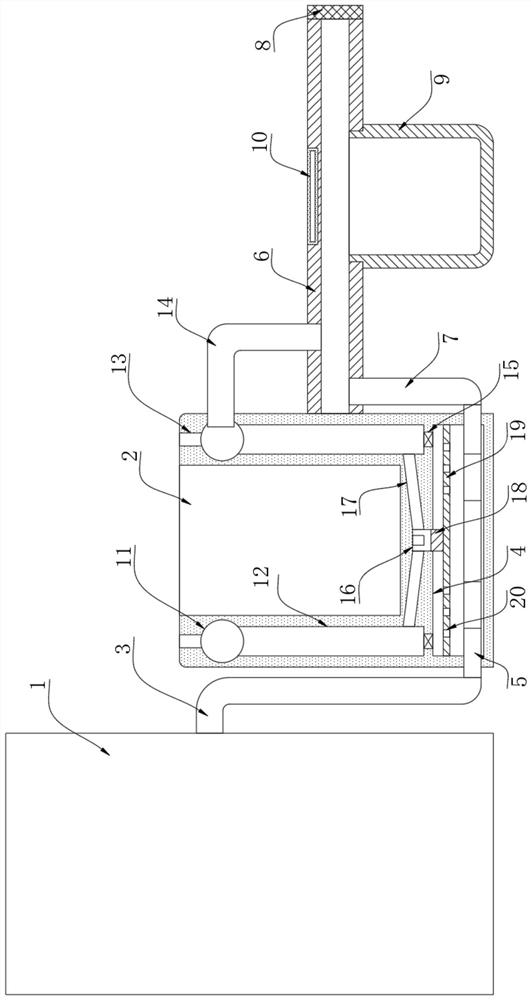

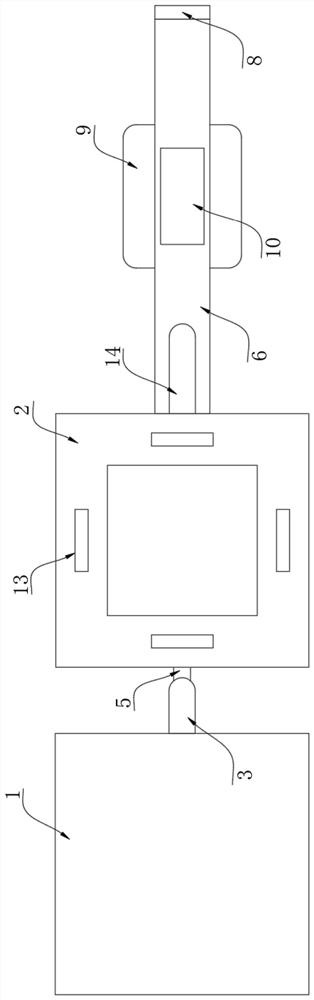

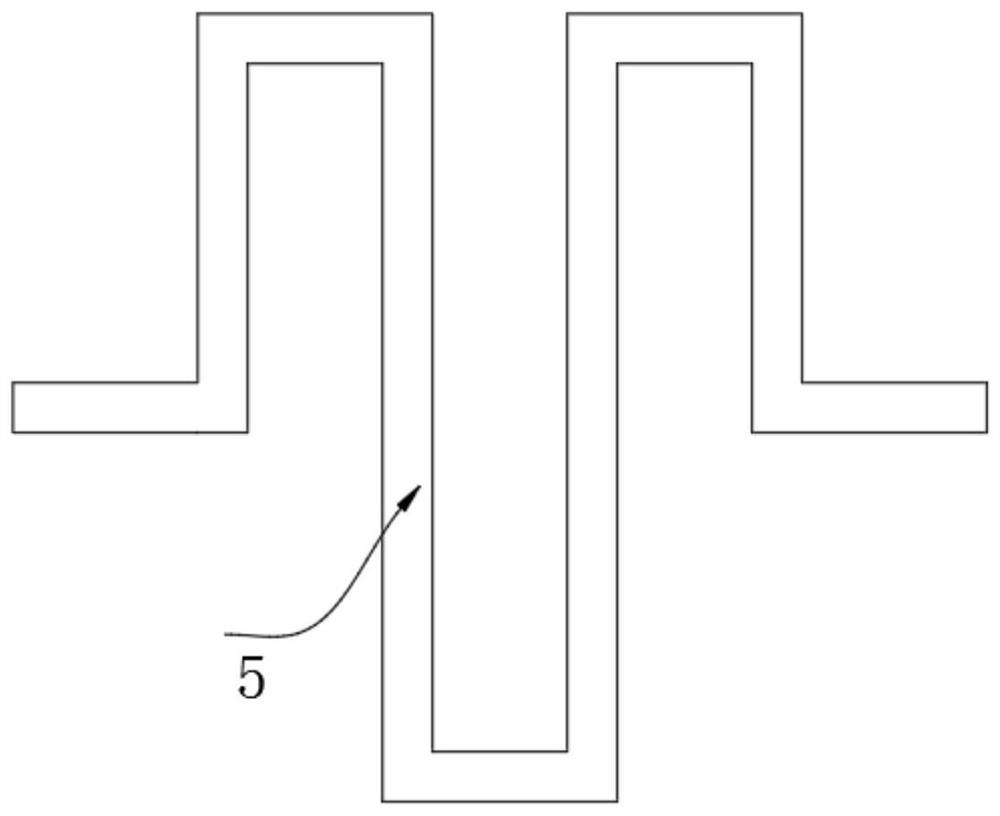

[0020] refer to Figure 1-3 , an energy-saving and environment-friendly garbage incineration system, comprising an incinerator 1 and a smoke exhaust pipe 3 for the exhaust of the incinerator 1, a pretreatment box 2 and a discharge pipe 6 fixed on the pretreatment box 2, the pretreatment box 2 There is a heating chamber 4 in the lower part, and a heating tube 5 is inserted through the side wall of the heating chamber 4. The heating tube 5 is arranged in a circle inside the heating chamber 4 to expand the heat dissipation range, increase the time of passing through the heating chamber 4, and make full use of the heat of the flue gas. , to achieve effective waste heat utilization, the bottom of the discharge pipe 6 is inserted with a discharge pipe 7, the two ends of the heating pipe 5 are respectively connected with the smoke exhaust pipe 3 and the discharge pipe 7, and the side wall of the pretreatment box 2 is provided with an annular ventilation chamber 11. There are four dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com