Multistage Stirling engine and steady-state operation parameter regulating and controlling method thereof

A Stirling machine and mechanical energy technology, applied in the field of multi-stage Stirling machine and its steady-state operation parameter control, can solve the problem of poor adaptability of piston pump gas, inability to reduce the unit cost of Stirling engine, and increase the complexity of equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

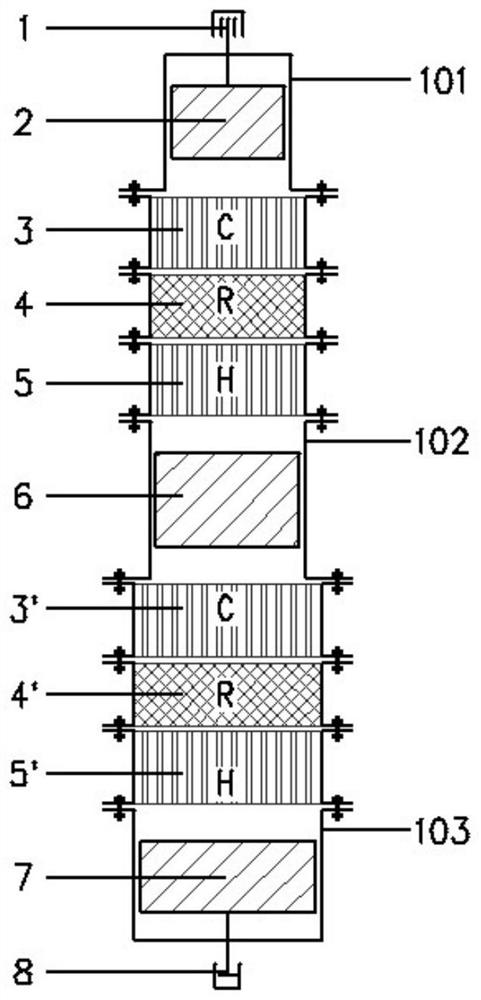

[0122] A multistage Stirling machine (as attached figure 2 As shown), a mechanical energy input device 1 is arranged at one end thereof, and the mechanical energy input device 1 is connected with the mechanical energy input piston 2, and the mechanical energy input piston 2 is arranged in the first cylinder 101; the first cylinder 101 passes through the first radiator 3, the second A regenerator 4, the first heat absorber 5 communicate with the second cylinder 102, and the second cylinder 102 is provided with a mechanical energy transfer double-acting free piston 6; the second cylinder 102 passes through the second radiator 3', the second regenerator 4'. The second heat absorber 5' communicates with the last-stage cylinder 103, and the mechanical energy output piston 7 is arranged in the last-stage cylinder 103; the other end of the mechanical energy output piston 7 is connected with the mechanical energy output device 8. A closed working space is formed between the mechanical ...

Embodiment 2

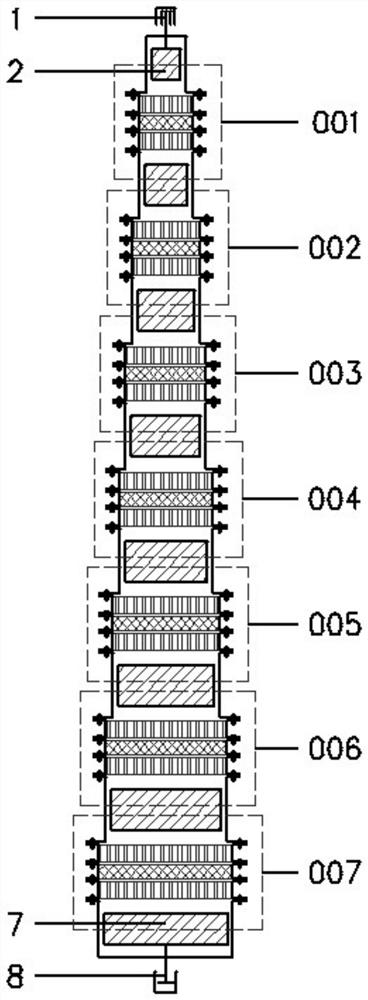

[0124] A kind of multi-stage Stirling machine, a mechanical energy input device 1 is arranged at one end thereof, the mechanical energy input device 1 is connected with a mechanical energy input piston 2, and the mechanical energy input piston 2 is arranged in a first cylinder 101; the first cylinder 101 passes through the first The radiator 3, the first regenerator 4, and the first heat absorber 5 communicate with the second cylinder 102, and the second cylinder 102 is provided with a mechanical energy transfer double-acting free piston 6; the second cylinder 102 passes through the second radiator 3', The second regenerator 4' and the second heat absorber 5' communicate with the third cylinder, and the third cylinder is equipped with a mechanical energy transfer double-acting free piston; the third cylinder passes through the radiator, heat regenerator, heat absorber and the final The first stage cylinder 103 is connected, and the mechanical energy output piston 7 is arranged ...

Embodiment 3

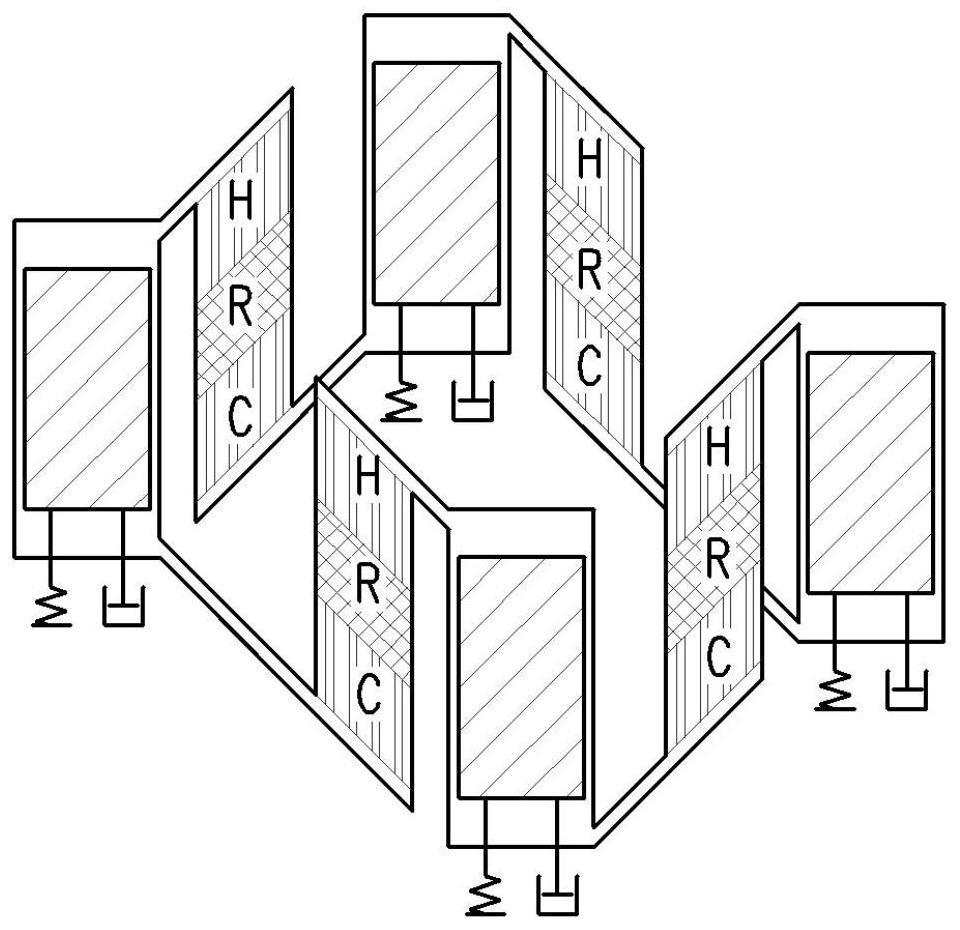

[0126] A multi-stage Stirling engine that utilizes the exhaust heat of an internal combustion engine. Biogas power generation generally uses internal combustion engines. The exhaust temperature of internal combustion engines is about 500°C. It is generally used for heat preservation of biogas tanks. The waste heat cannot be fully utilized in the three seasons of spring, summer and autumn every year due to low heat preservation requirements. In this embodiment, the exhaust gas is used to heat the temperature of the heat transfer oil from 300°C to 350°C as the heat source of the multi-stage Stirling engine, so as to realize efficient utilization of exhaust heat. The cold source adopts the thermal insulation water of the biogas tank, and the temperature of the thermal insulation water is heated from 50°C to 90°C to realize the utilization of low-temperature waste heat. The multi-stage Stirling engine of this embodiment is as attached image 3 As shown, the vertical arrangement i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com