Combined type reaming method and device

A combined and reaming drill bit technology, which is applied in drilling equipment and methods, earthwork drilling, percussion drilling, etc., can solve the problems of low work efficiency, difficulty in drilling back, low reliability, etc., and achieve wear resistance And good stability, fast and efficient reaming, and the effect of improving reaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention provides a joint reaming method, which includes the following steps:

[0027] 1) Drilling location: Measure and pay off according to coal seam conditions to locate the drilling location;

[0028] 2) Drilling: First, use an ordinary gas extraction rig to drill an ordinary borehole through the rock layer into the coal seam, stop drilling after the ordinary borehole depth reaches the design position, and withdraw the ordinary bit;

[0029] 3) Reaming: adopting a combination of hydraulic reaming and mechanical flexible reaming for flexible joint reaming;

[0030] 31) Hydraulic reaming, using a hydraulic cutting head with a high-pressure nozzle in the radial direction for hydraulic reaming

[0031] 32) Mechanical flexible reaming. A flexible reaming bit is connected to the rear end of the hydraulic cutting head, and the flexible reaming bit is used for mechanical flexible reaming. The flexible reaming bit is driven by a drill rod with a geared motor. The hole dr...

Embodiment 2

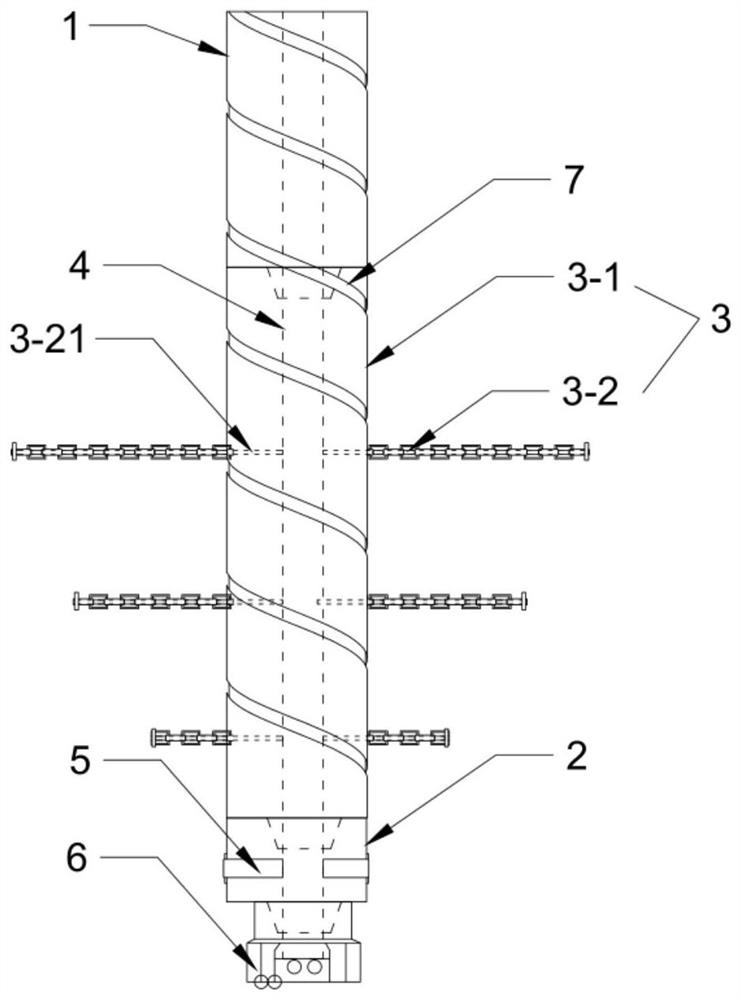

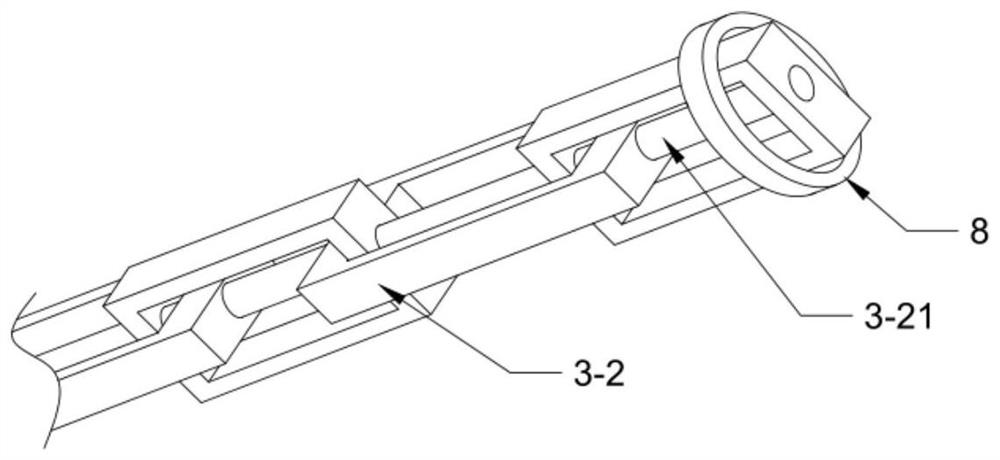

[0033] Such as Figure 1~2 As shown, the present invention also provides a combined reaming device, which includes a drill pipe 1, a hydraulic cutting head 2 and a flexible reaming drill bit 3. One end of the drill pipe 1 is in transmission connection with a geared motor (not shown in the figure) , The other end is fixedly connected to the flexible reaming drill bit 3, the hydraulic cutting head 2 is connected to the end of the flexible reaming drill bit 3 away from the drill pipe 1, the drill pipe 1, the flexible reaming drill bit 3 and the hydraulic cutting head 2 are provided There are intersecting high-pressure water channels 4, the outer circular surface of the hydraulic cutting head 2 is provided with a plurality of high-pressure nozzles 5 along the radial direction, and the end of the hydraulic cutting head 2 away from the flexible reaming drill bit 3 is also connected with a tunneling drill bit 6, The flexible reaming drill bit 3 includes a reaming seat 3-1 and a swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com