A symmetrical eccentric spindle assembly hammer mill

A technology for assembling hammers and pulverizers, which is applied in grain processing, etc., can solve the problems of reduced sieving efficiency of crushed materials, reduced work efficiency, and low opening rate of screen mesh, so as to reduce screen blocking faults and improve work efficiency , Improve the effect of sieving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

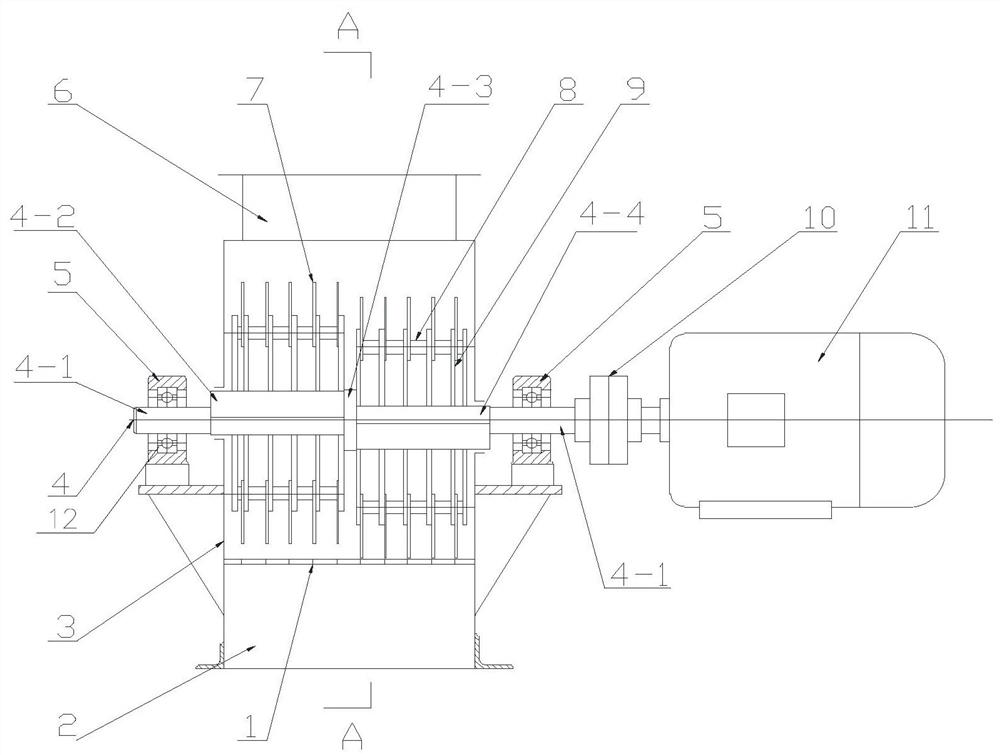

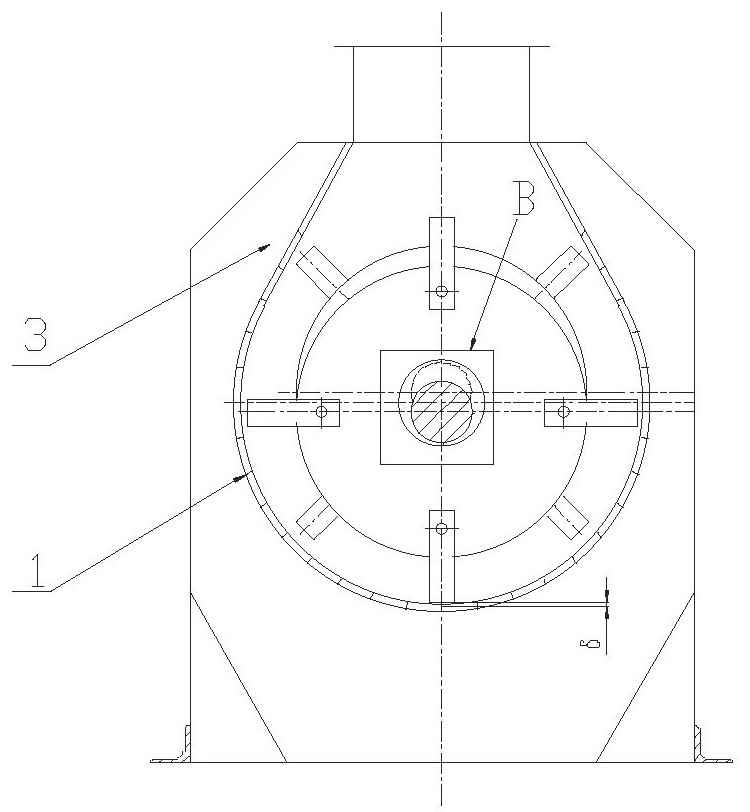

[0016] The symmetrical eccentric spindle assembly hammer mill of this embodiment, such as Figure 1-3 As shown, it includes a crushing bin 3, which is provided with a crushing main shaft 4, a screen 1, and several hammer blades 7 installed on the crushing main shaft 4. The crushing bin 3 is fixed on the foundation, and its upper part is a feeding Port 6, the lower part is the discharge port 2, and a bearing seat 5 is fixedly connected to the left and right sides of the crushing bin 3, and the two ends of the crushing main shaft 4 are installed on the housing of the crushing bin 3 through two bearings 12.

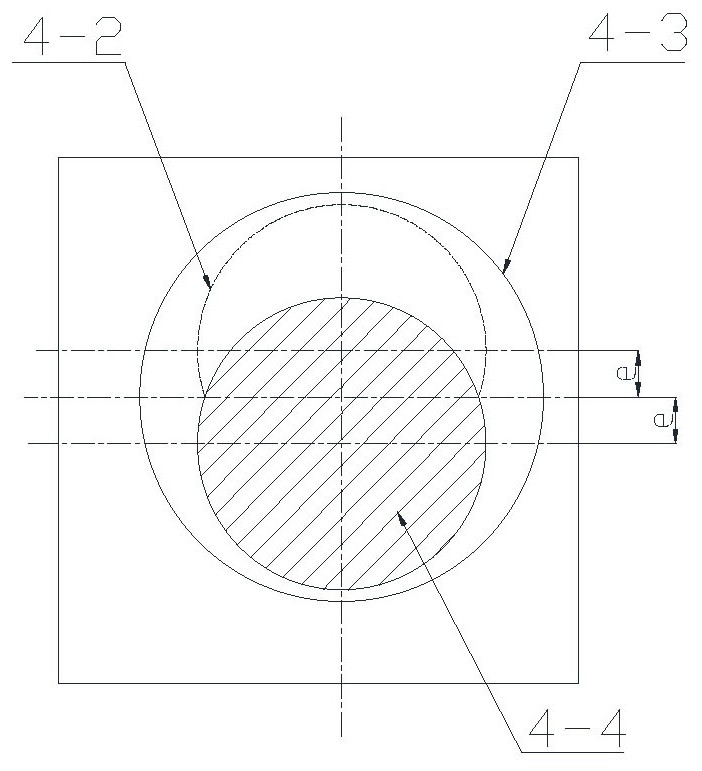

[0017] The crushing main shaft 4 is an integral part, which is successively divided into a left connecting section 4-1, a left eccentric section 4-2, an intermediate shaft shoulder 4-3, a right eccentric section 4-4 and a right connecting section 4-5. The left connection section 4-1 and the right connection section 4-5 are symmetrically arranged left and right and also serve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com