Dust removal and denitration method

A denitrification and square technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve problems such as waste, blockage of screen meshes, and primary filtration of smoke and dust affecting flue gas transportation, so as to improve the utilization rate, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] as attached figure 1 to attach Figure 9 Shown:

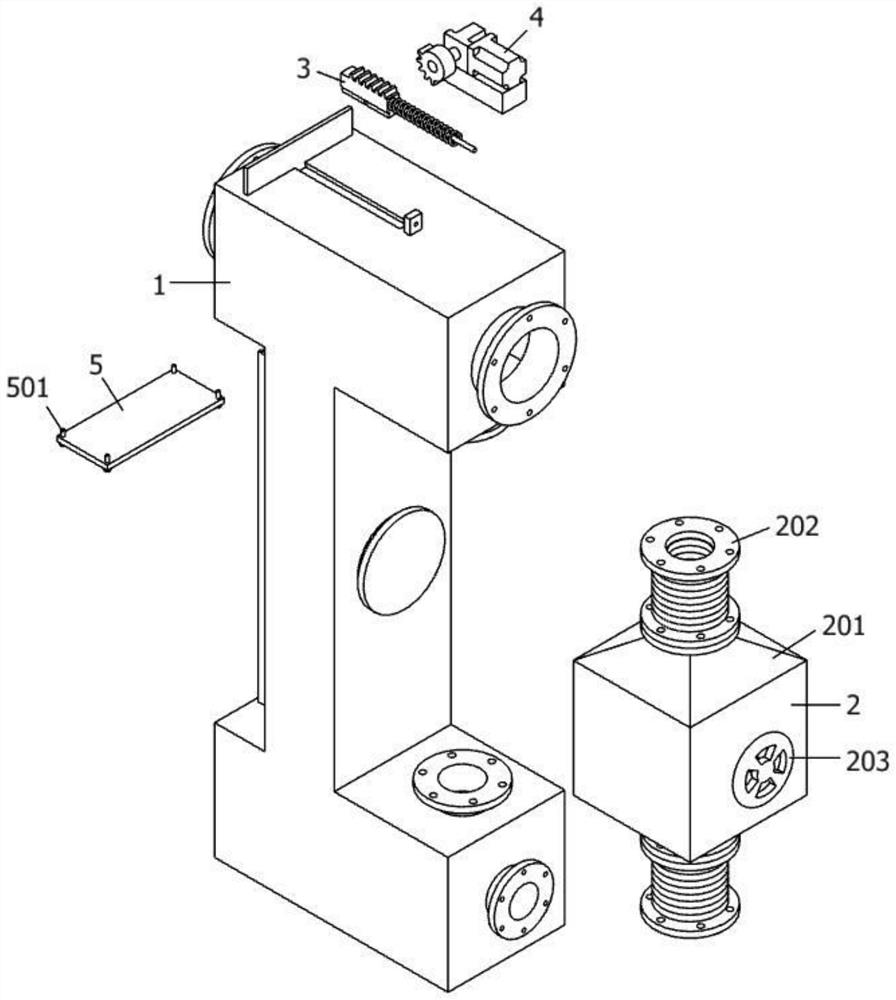

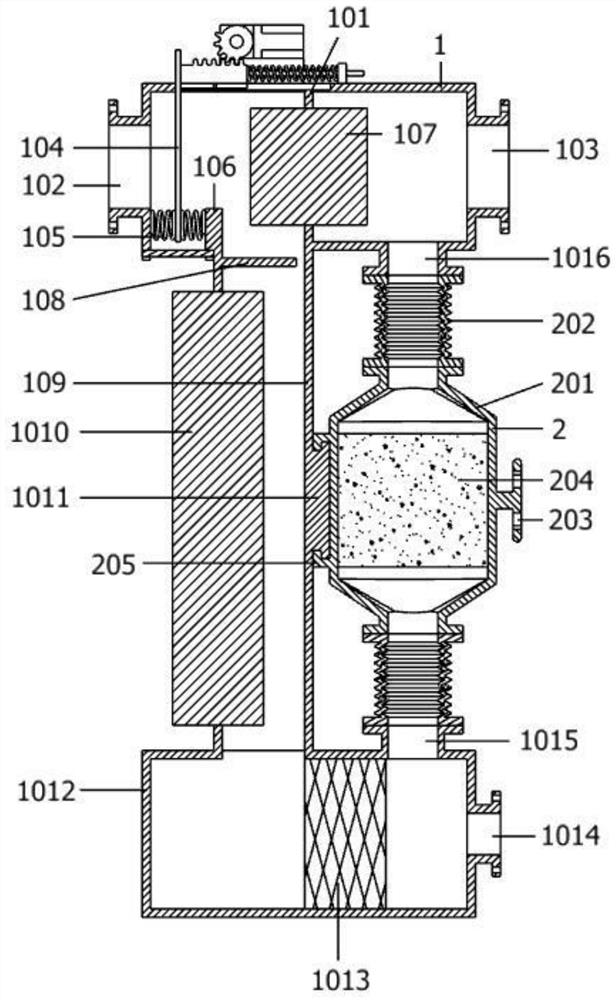

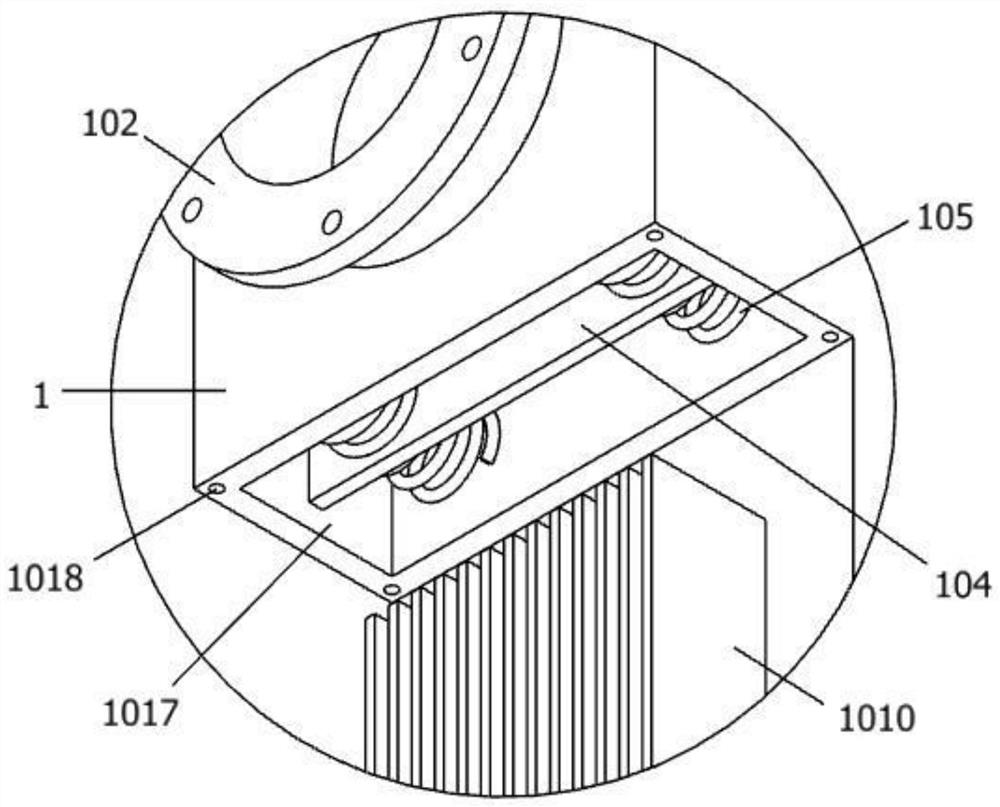

[0036] The present invention provides a dust removal and denitrification method. The method realizes dust removal and denitrification through an integrated dust removal and denitrification device equipped with an upper rectangular housing 1, a square housing 2, an intermittent dust removal mechanism 3, a driving mechanism 4, and a rectangular plate 5;

[0037] The dust removal and denitrification integrated equipment includes: an upper rectangular housing 1, a square housing 2 is arranged on the lower right side of the upper rectangular housing 1; an intermittent dust cleaning mechanism is installed slidingly on the left side of the top surface of the upper rectangular housing 1 3. On the left side of the top surface of the upper rectangular housing 1, a driving mechanism 4 is fixedly installed in engagement with the intermittent dust cleaning mechanism 3; on the left side of the bottom surface of the upper rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com