Steamed pork roll production and processing equipment with automatic feeding and discharging functions and processing method thereof

A technology for automatic loading and unloading and processing equipment, which is applied in the direction of meat processing equipment, processed meat, food coating, etc. It can solve the problems of reduced production efficiency, blade shaking, and poor work efficiency of pig liver, so as to improve work efficiency, Improves support and improves stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

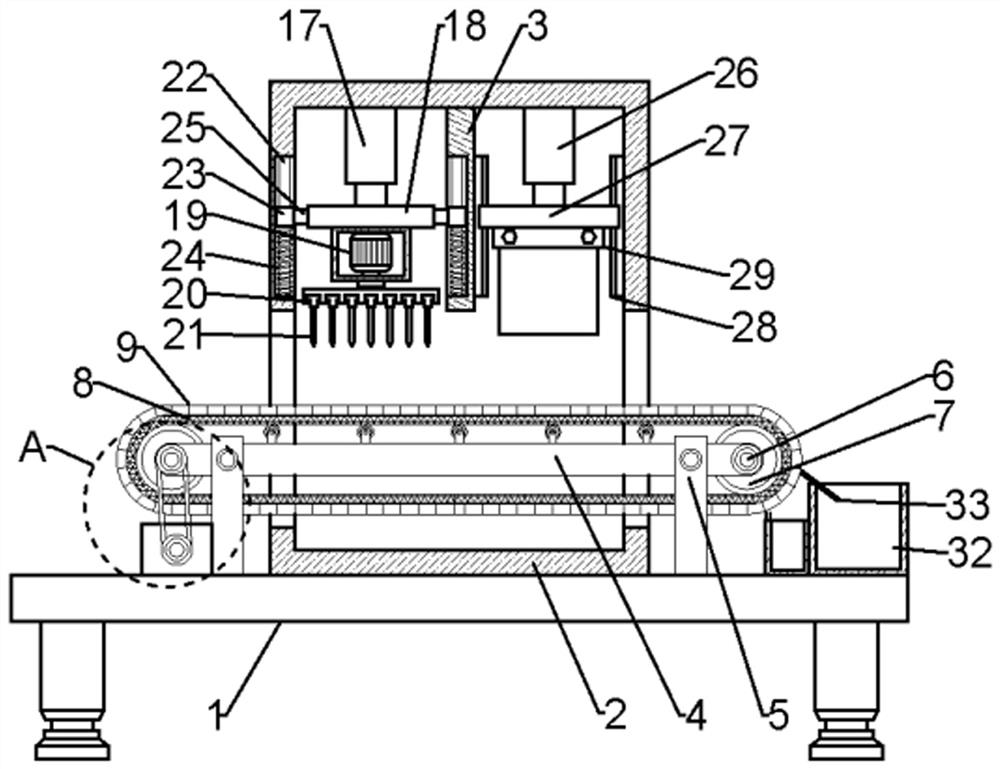

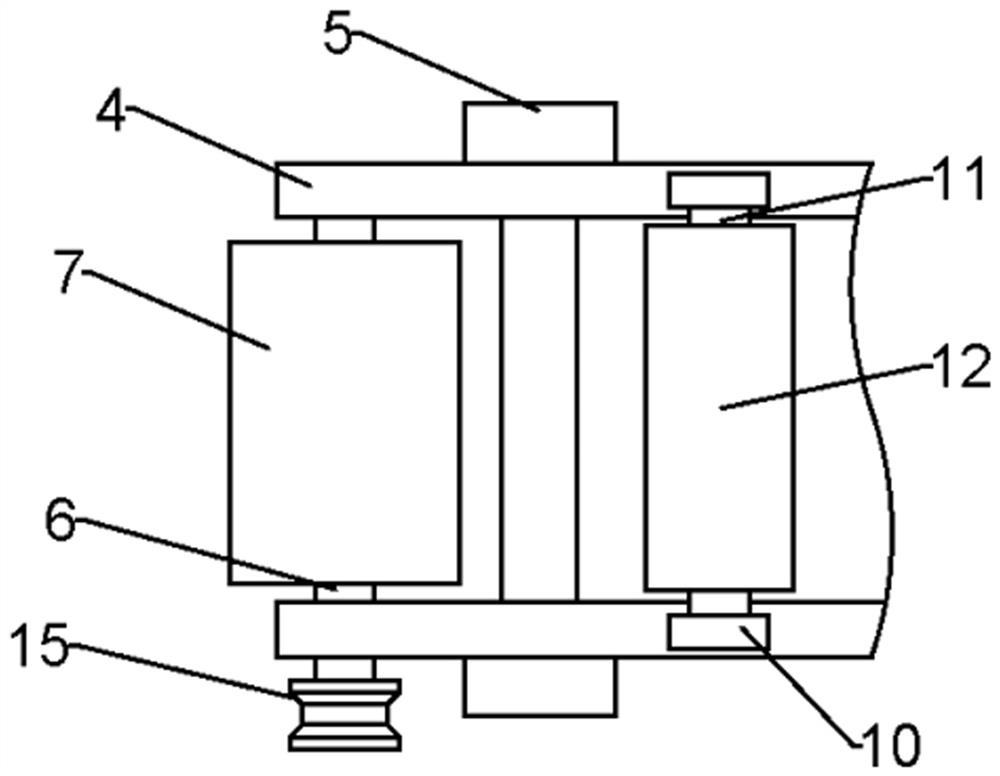

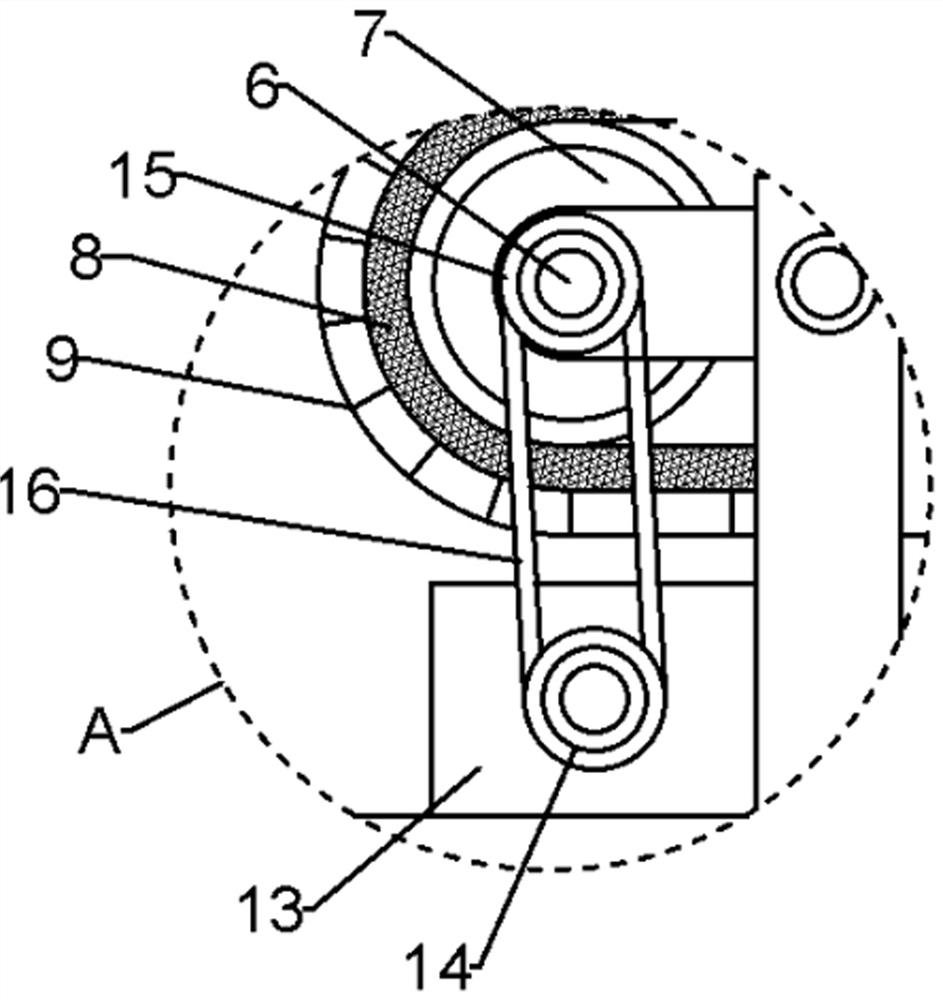

[0030] Embodiment 1: see Figure 1-4, roll meat production and processing equipment with automatic loading and unloading functions, including a base 1, the base 1 is a rectangular plate-shaped horizontally arranged, four corners of the bottom surface of the base 1 are vertically fixed with supporting legs, and the base The middle part of the top surface of 1 is fixed with a rectangular cutting box 2, and a rectangular feeding port and a discharging port are respectively provided at the lower parts of both sides of the cutting box 2; A conveying assembly is arranged horizontally between the outlet and the discharge port, and a rectangular partition plate 3 is provided on the top vertical fixing nail in the cutting box 2. The slitting assembly and the cross-cutting assembly; the conveying assembly includes a rectangular frame 4, a support column 5, a rotating shaft 6, a drum 7, a metal mesh belt 8 and a scale plate 9, and at the inlet and outlet of the cutting box 2 A rectangul...

Embodiment 2

[0034] Example 2: see Figure 5 , in the present embodiment, the present invention also proposes the processing method of the meat roll production and processing equipment with automatic loading and unloading function, comprising the following steps:

[0035] Step 1, firstly connect the first motor 13, the electric push cylinder 17, the second motor 19 and the electric push rod 26 to the external power supply through wires respectively; then the staff cleans all the required materials, and then cuts the The pork liver is scalded with boiling water and dried;

[0036] Step 2, then the dried pig liver in step 1 is placed on the surface of the scale plate 9, then the first motor 13 is controlled to drive the driving pulley 14 to rotate, and then the driving pulley 14 drives the passive pulley 15 to rotate through the belt 16, The rotation of the driven pulley 15 drives the rotating shaft 6 to rotate, the rotation of the rotating shaft 6 drives the drum 7 to rotate, the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com