Quick assembly type guardrail

An assembled guardrail technology, which is applied in the direction of fences, building types, buildings, etc., can solve the problems of welding guardrail processing troubles, high repair and maintenance costs, and low labor efficiency, so as to avoid Faraday shielding effect and facilitate installation. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

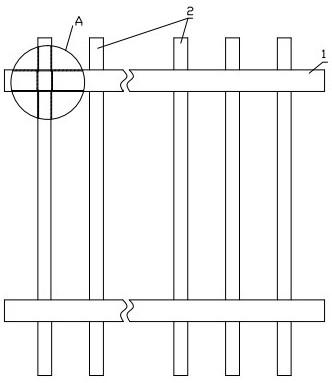

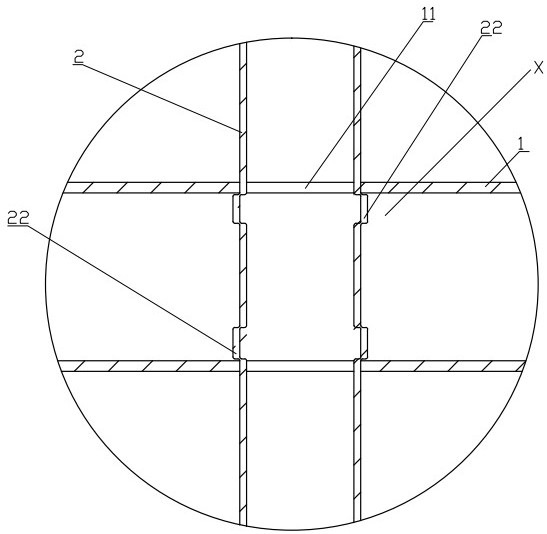

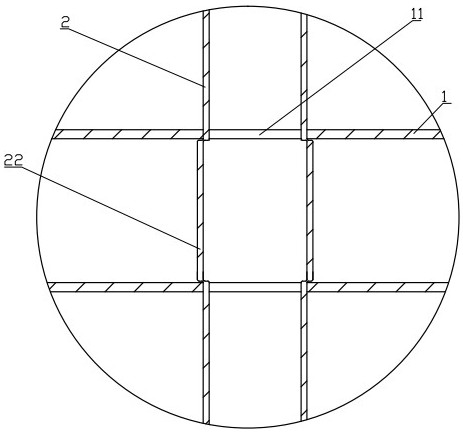

[0024] as attached figure 1 and figure 2 As shown, the embodiment of the quick-assembled guardrail provided by the present invention includes a plurality of crossbeams 1 arranged at intervals and arranged horizontally and longitudinal beams 2 arranged at intervals and arranged vertically. In this embodiment, the crossbeams and The longitudinal beams are all made of square tubes, and two cross beams are provided. The cross beams are provided with a plurality of insertion holes 11 arranged at intervals and vertically through, and the insertion holes of the adjacent upper and lower beams are vertically aligned. , on the opposite two pipe walls on the square pipe are processed opposite through holes, the two opposite through holes and the inner cavity of the square pipe between the two through holes jointly form the insertion hole, the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com