Ice and snow quick-melting agent

A technology of ice and snow and calcium chloride, which is applied in the field of compound salt, can solve the problems of metal and cement concrete corrosion, slow snow removal speed, harmful plants, etc., and achieve the effect of reduced corrosion, fast ice melting and snow removal speed, and reduced corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

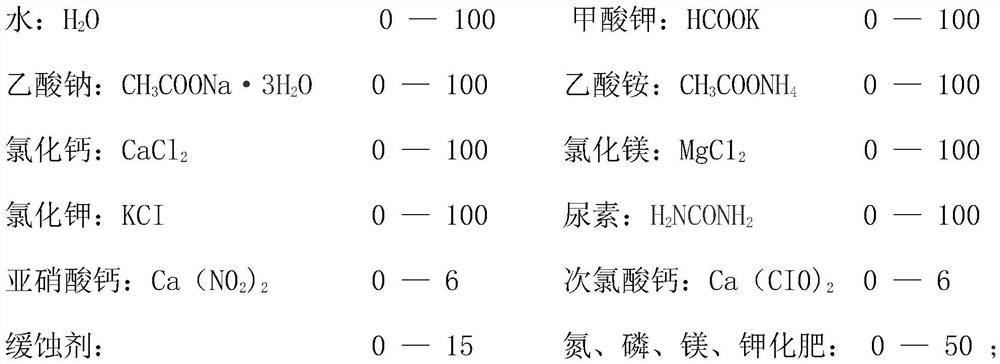

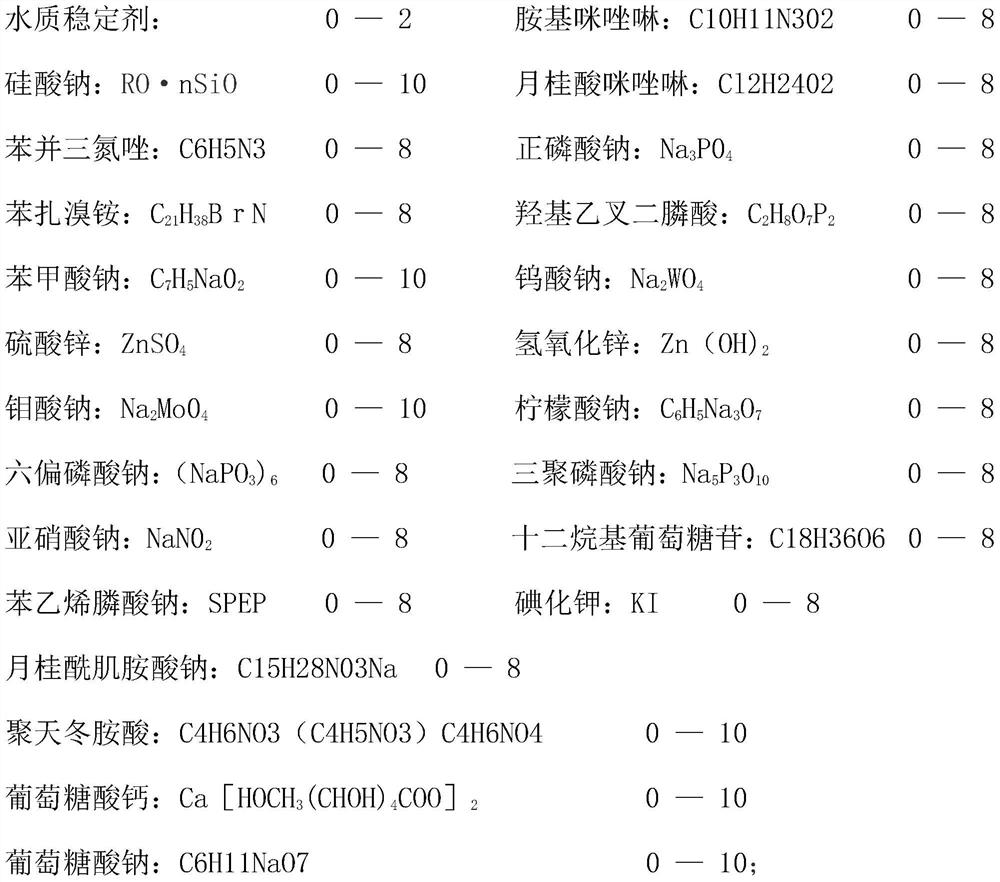

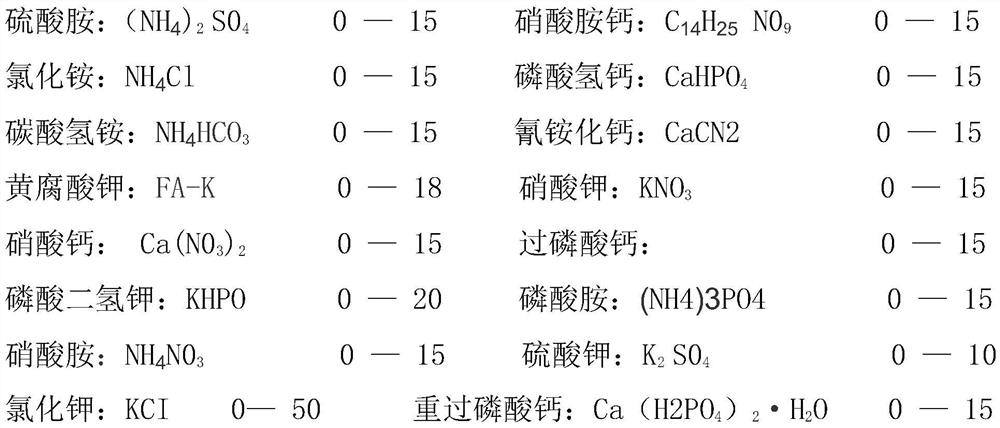

[0055] It is used when the minimum temperature is above -12°C, and the external environment is: various bridges with reinforced concrete structures, airport roads, docks, elevated roads and expressways, when the traffic roads are covered with ice and snow, and when motor vehicles are driving intensively. Its technical formula is components by weight: (1=100kg / consumption)

[0056]

[0057] Potassium formate, sodium acetate and ammonium acetate, their sulfate ion SO 4 2— The content of calcium hypochlorite is zero, which can effectively reduce the corrosion of steel bars and concrete for reinforced concrete structures, docks, airport roads, etc. Calcium hypochlorite has many functions such as bleaching and deblackening, deodorization and deodorization, disinfection and sterilization of water after melting ice and snow. For this function, urea acts as an activator in this technical formula, making it react quickly and speed up the speed of ice melting and snow removal.

[0...

Embodiment 2

[0060] It is used when the minimum temperature is above -16°C, and the external environment is: airport roads, viaducts, overpasses, docks, traffic roads are covered with ice and snow, and when motor vehicles are driving intensively. Its technical formula is components by weight: (1=100kg / consumption)

[0061]

[0062] Potassium formate and its sulfate ion SO 4 2— The content of urea is zero, which can effectively reduce the corrosion of steel bars and concrete for reinforced concrete structures, docks, airport roads, etc. Urea participates in the combination of potassium formate in this technical formula and acts as an activator to make it respond quickly. Accelerate the speed of melting ice and snow, and calcium hypochlorite has multiple functions such as bleaching and deblackening, deodorization and deodorization, disinfection and sterilization of water after ice and snow melt.

[0063] First of all, according to the technical formula combination of ice and snow quick-...

Embodiment 3

[0065] It is used when the minimum temperature is above -18°C, and the external environment is: airport roads, viaducts, overpasses, docks, traffic roads are covered with ice and snow, and when motor vehicles are driving intensively. Its technical formula is components by weight: (1=100kg / consumption)

[0066]

[0067]

[0068] First of all, according to the technical formula combination of ice and snow quick-melting agent, various chemical raw materials required are inspected. After the inspection is determined to meet the quality standards, potassium formate: 5500kg; sodium acetate: 3500kg; urea: 800kg; zinc sulfate: 340kg; sodium silicate: 30kg; calcium gluconate 90kg; lauryl glucoside: 90kg; sodium tungstate: 50kg. The material is placed in the mixer and allowed to stir to make it evenly stirred; again, it is placed in the granulator for granulation, so that it can reach the quality standard of 1mm ~ 6mm solid particles; finally, it will meet the quality standard Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com