Design method for integrated case and charging pile of automated guided vehicle (AGV) and system

A technology of automatic guided vehicles and design methods, which is applied in the direction of electric vehicle charging technology, charging stations, electrical devices, etc., and can solve the problems of small space for design improvement, high maintenance difficulty, difficult function replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0060] This embodiment provides an integrated chassis and charging pile design scheme applied to unmanned guided vehicles. The implementation of the scheme specifically includes the following steps:

[0061] S1, the functional module design of the integrated chassis and charging pile.

[0062] S2. Schematic design of control board and charging control board.

[0063] S3, PCB design of control board and charging control board.

[0064] S4, the circuit assembly of the control board and the charging control board.

[0065] S5, the appearance design of the integrated chassis and charging pile.

[0066] S6. Assembly of integrated chassis and charging pile.

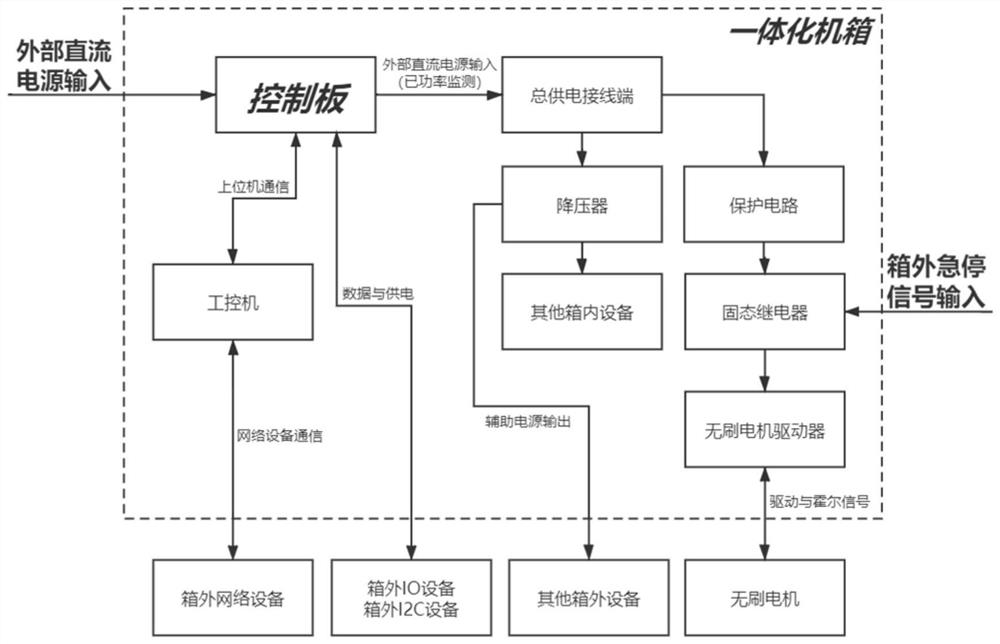

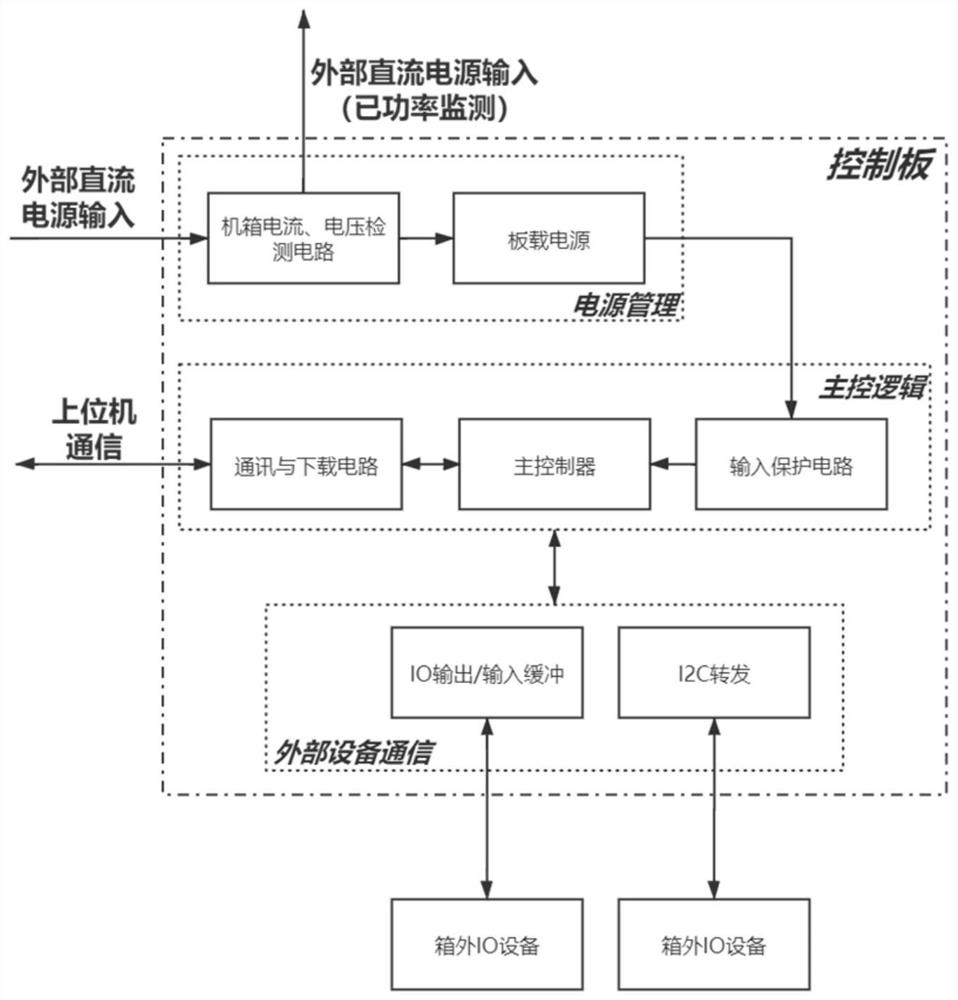

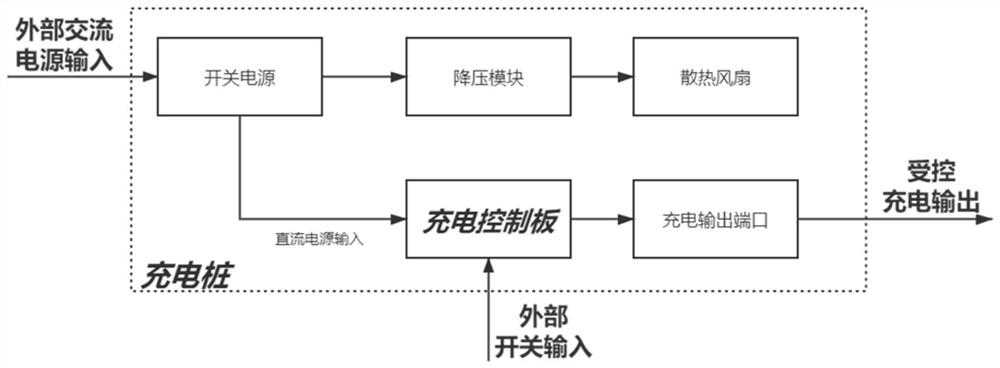

[0067] During the implementation of step S1, a rough function distribution block diagram is obtained, such as figure 1 , figure 2 , image 3 with Figure 4 shown.

[0068] During the implementation of step S2, the schematic diagram design is performed using Electronic Design Automation (EDA) software.

[0069] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com