Preparation method and application for aloe flower extracting solution

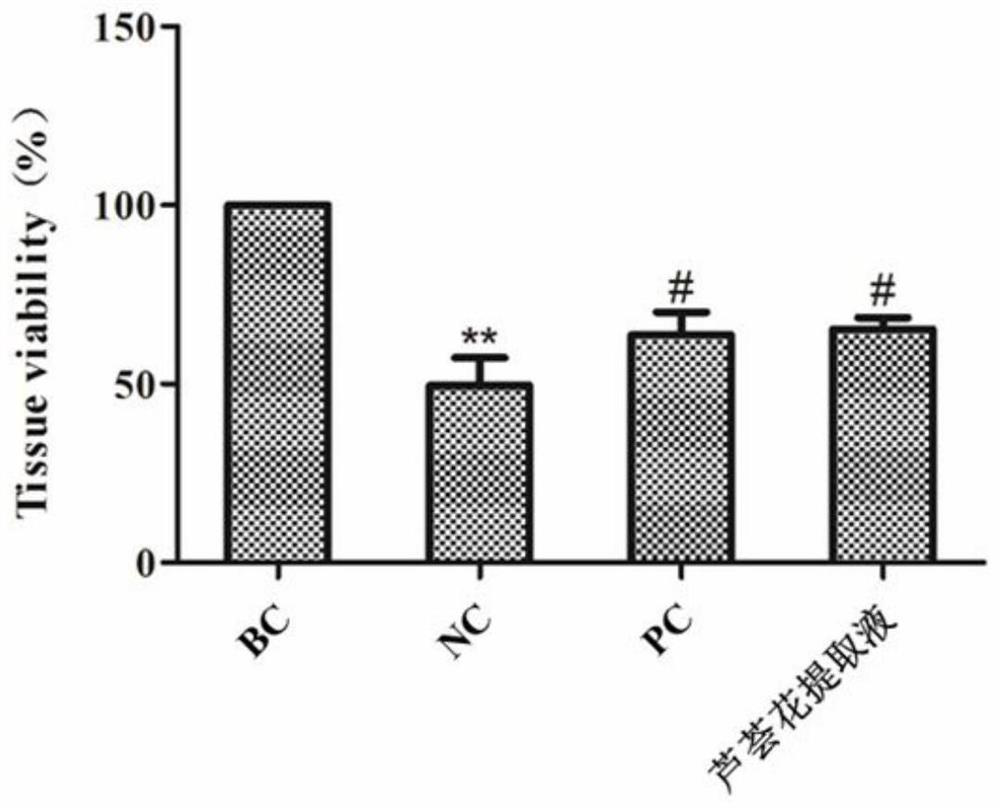

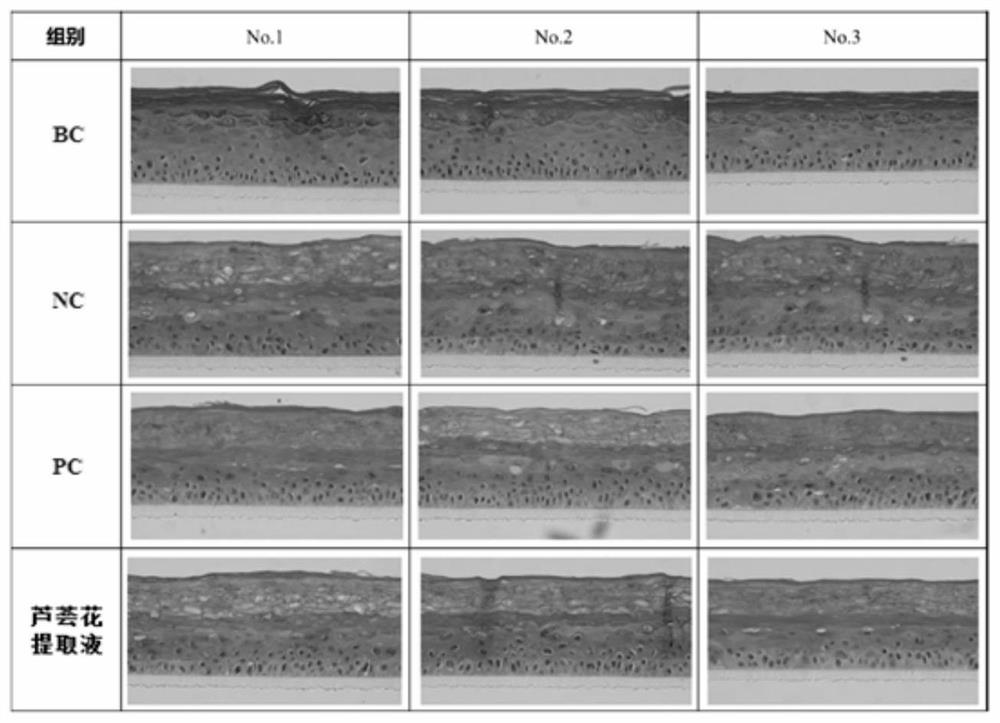

A technology for flower extraction and aloe, which is applied in the field of preparation of aloe flower extracts, can solve problems such as inability to effectively remove and affect product stability, and achieves improved product quality and quality stability, improved anti-pollution ability, and inhibited tyrosine The effect of enzymatic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation technology of aloe flower extract, comprises the following steps:

[0045] S1 Crude Extract Preparation

[0046] Take 50kg of aloe vera flowers, crush and sieve them, put them into the extraction tank, add 1700L of pure water as the extraction solvent, control the temperature in the extraction tank at about 60°C, keep the temperature for extraction for 2 hours, filter, add 500L of pure water to the filter residue, wash, filter, and combine the filtrates to obtain 2080L crude extract of aloe vera flower.

[0047] S2 crude extract pretreatment

[0048] The crude extract of aloe vera flowers was centrifuged through a tube-type high-speed centrifuge at a speed of 12000 r / min to obtain 2050 L of centrifuged liquid.

[0049] S3 microfiltration membrane desedimentation

[0050] The centrifuged liquid was separated by microfiltration using a ceramic membrane unit with a membrane pore size of 0.05 μm. The operating temperature was 50° C. and the operatin...

Embodiment 2

[0058] A kind of preparation technology of aloe flower extract, comprises the following steps:

[0059] S1 Crude Extract Preparation

[0060] Take 50kg of aloe vera flowers, crush and sieve them, put them into an extraction tank, add 800L of pure water as an extraction solvent, control the temperature in the extraction tank at about 80°C, keep the temperature for extraction for 1 hour, filter, add 500L of pure water to the filter residue, wash, filter, and combine the filtrates to obtain 1120L crude extract of aloe vera flower.

[0061] S2 crude extract pretreatment

[0062] The crude extract of aloe vera flowers was centrifuged through a disc high-speed centrifuge at a speed of 8000 r / min to obtain 1090 L of centrifuged liquid.

[0063] S3 microfiltration membrane desedimentation

[0064] The centrifuged liquid was separated by microfiltration using an organic membrane with a membrane pore size of 0.2 μm at an operating temperature of 40° C. and an operating pressure of 8 ...

Embodiment 3

[0072] A kind of preparation technology of aloe flower extract, comprises the following steps:

[0073] S1 Crude Extract Preparation

[0074] Take 50kg of aloe vera flowers, crush and sieve them, put them into the extraction tank, add 1000L pure water as the extraction solvent, control the temperature in the extraction tank at about 70°C, keep the temperature for extraction for 2 hours, filter, add 350L pure water to the filter residue, wash, filter, and combine the filtrates to obtain 1170L of aloe vera flower crude extract.

[0075] S2 crude extract pretreatment

[0076] The crude extract of aloe vera flowers is sent to the horizontal screw discharge centrifuge-disc high-speed centrifuge unit for centrifugal separation through the pipeline, wherein the drum speed of the horizontal screw discharge centrifuge is 2000r / min, and the differential speed is 30r / min; The speed of the centrifuge was 10000r / min, and 1150L of centrate was obtained.

[0077] S3 microfiltration membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com