Composite chemical nickel remover and application thereof

A chemical nickel and remover technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve problems such as poor effect, achieve improved COD removal effect, simplify treatment procedures, and remove chemical nickel Effects of Chemical Phosphorus Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of compound chemical nickel removal agent, by ferrous sulfate, ferric chloride, Al(NH 3 ) 3 , aluminum chloride, NaClO 3 , sulfonic acid, additives and water are polymerized in proportion.

[0020] Its mass ratio is 0.35:0.25:0.10:0.05:0.05:0.05:0.08:0.07.

[0021] Take a 1L glass beaker, add 70ML water, turn on the mixer, and slowly add FeSO into the beaker 4 .7H 2 O 350G, after ten minutes slowly add solid FeCl to the beaker 3 250G, at this time the beaker starts to release heat, continue to add AlCl to the beaker 3 50G, continue to stir when the temperature reaches about 40°C, add 20ML of dissolved sulfonic acid, stir for 15 minutes, continue to add dissolved Al(NH 3 ) 3 100ML, add NaClO after 5 minutes 3 50G, when the temperature continues to rise to about 80°C, add 80G of additives, continue to stir and react for 1 hour, and after aging for 24 hours, a composite chemical nickel remover is obtained.

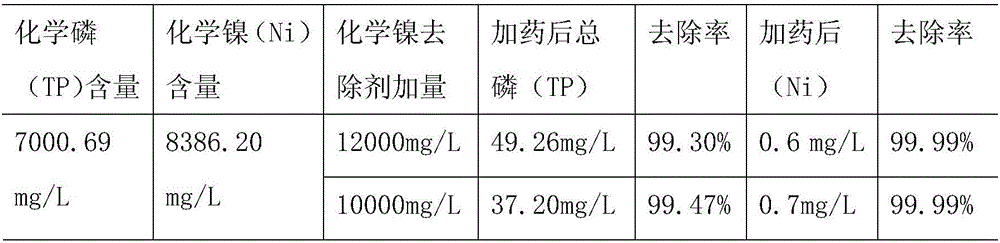

[0022] Utilize above-mentioned compound chemi...

Embodiment 2

[0027] Identical with the component of embodiment 1 and operating condition, difference is: this a kind of composite chemical nickel remover, this composite chemical nickel remover is made of ferrous sulfate, ferric chloride, Al(NH 3 ) 3 , aluminum chloride, NaClO 3 , sulfonic acid, additives, and water are polymerized in proportion.

[0028] Its mass ratio is 0.30:0.30:0.08:0.07:0.05:0.05:0.08:0.07.

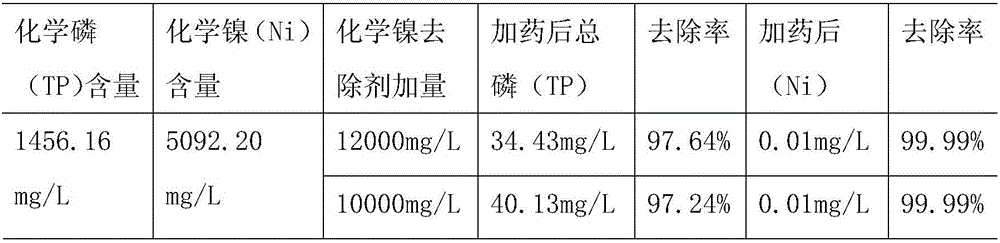

[0029] Take a 1L glass beaker, add 70ML water, turn on the mixer, and slowly add solid FeCl to the beaker 3 300G, after ten minutes slowly add FeSO into the beaker 4 .7H 2 O 300G, at this time the beaker starts to release heat, continue to add AlCl to the beaker 3 70G, continue to stir when the temperature reaches about 40°C, add 20ML of dissolved sulfonic acid, stir for 15 minutes, continue to add dissolved Al(NH 3 ) 3 80ML, add NaClO after 5 minutes 3 50G, when the temperature continues to rise to about 80°C, add 80G of additives, continue to stir and react for 1 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com