Ultrasonic electronic cigarette atomization core, atomizer and ultrasonic electronic cigarette

An electronic vaping device and electronic smog technology, which is applied in the field of electronic cigarettes, can solve the problems that the ultrasonic electronic vaping device does not realize modularization, affects the atomization effect of ultrasonic atomizing sheets, and has high maintenance and use costs, so as to improve the taste of vape , simple structure, low cost of use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

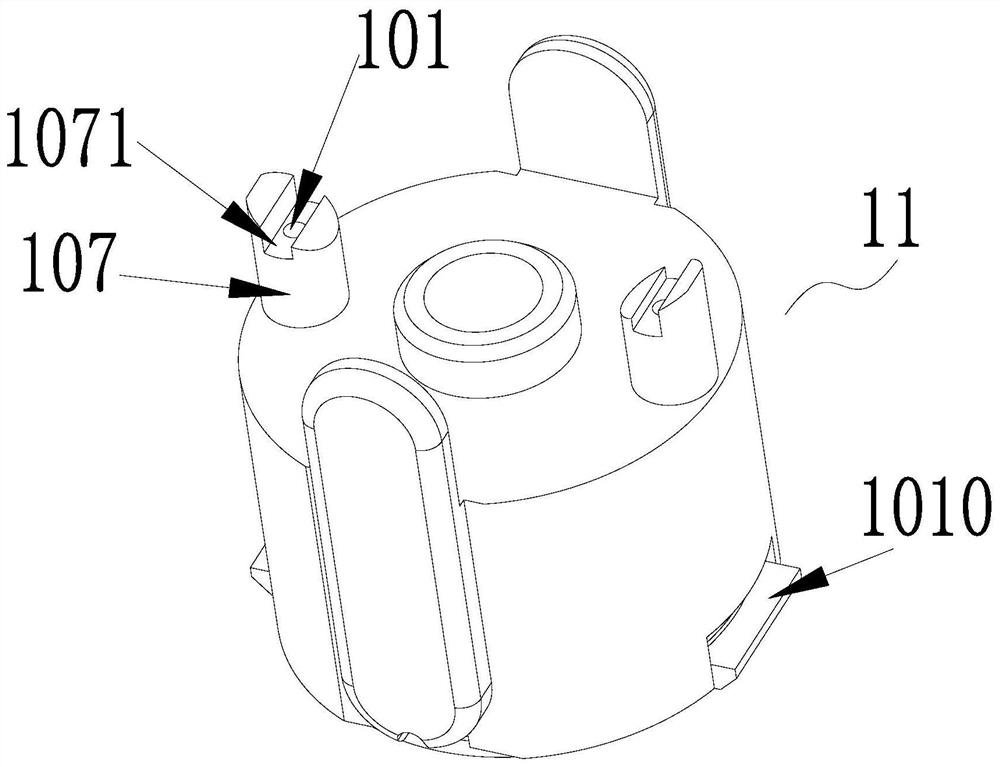

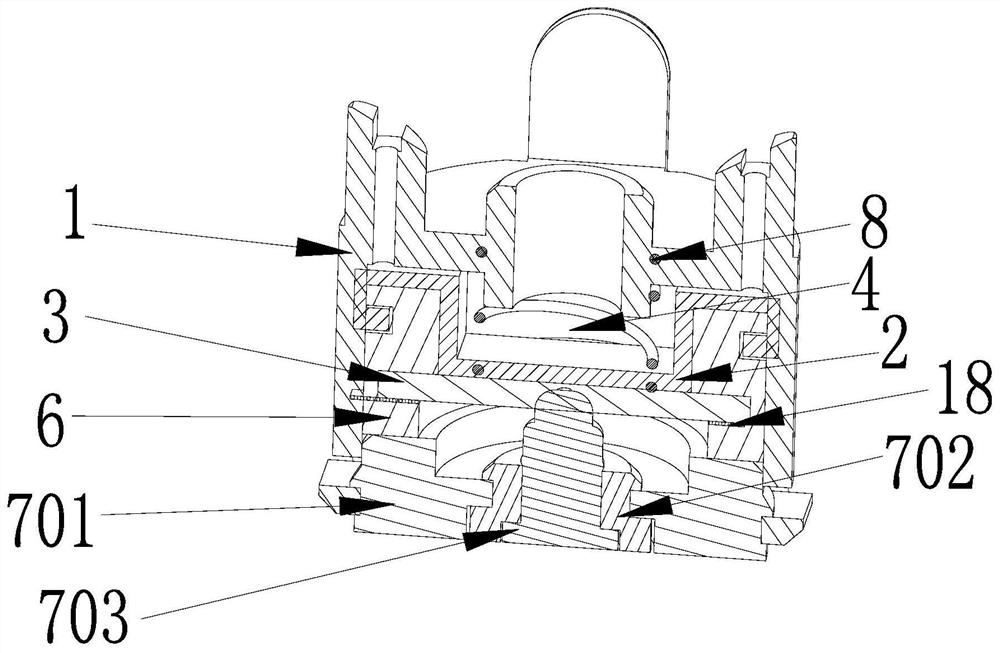

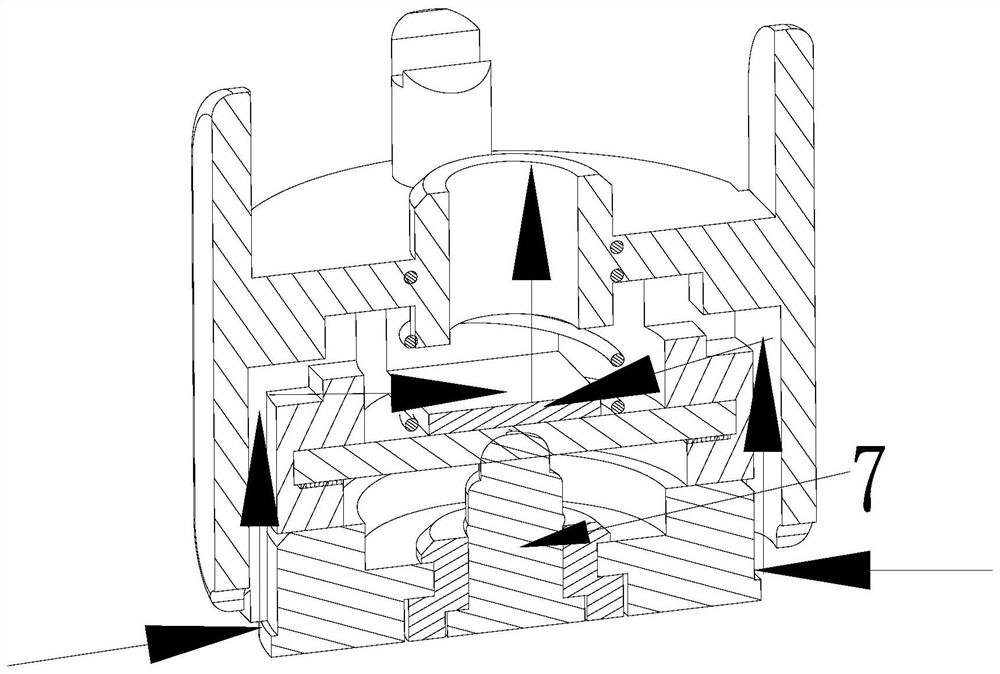

[0051] Such as Figure 1 to Figure 14 As shown, the ultrasonic electronic atomization core 11 includes a base 1, an oil guiding mechanism 2 and an ultrasonic atomizing sheet 3, the oil guiding mechanism 2 and the ultrasonic atomizing sheet 3 are fixed in the base 1, and the oil guiding mechanism 2 and the ultrasonic atomizing sheet The atomizing surfaces of the sheets 3 are in contact with each other, and the base 1 is also provided with a drainage column 107, and an oil inlet hole 101 connecting the outside world and the oil guide mechanism 2 is opened on the drainage column 107.

[0052] The oil supply unit 9 corresponding to the atomizing core 11 is provided with a sealing plug 17 that seals the oil tank 10. During the production process, the oil tank 10 of the oil supply unit 9 is pre-injected with e-liquid, and the atomizing core 11 and the During the connection process of the oil supply unit 9, the drainage column 107 on the atomizing core 11 pierces the sealing plug 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com