High-resolution industrial imaging equipment and imaging method for curved surface

An imaging device and high-resolution technology, applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the contradiction between high resolution and narrow depth of field, to expand the effective range, improve detection accuracy and detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

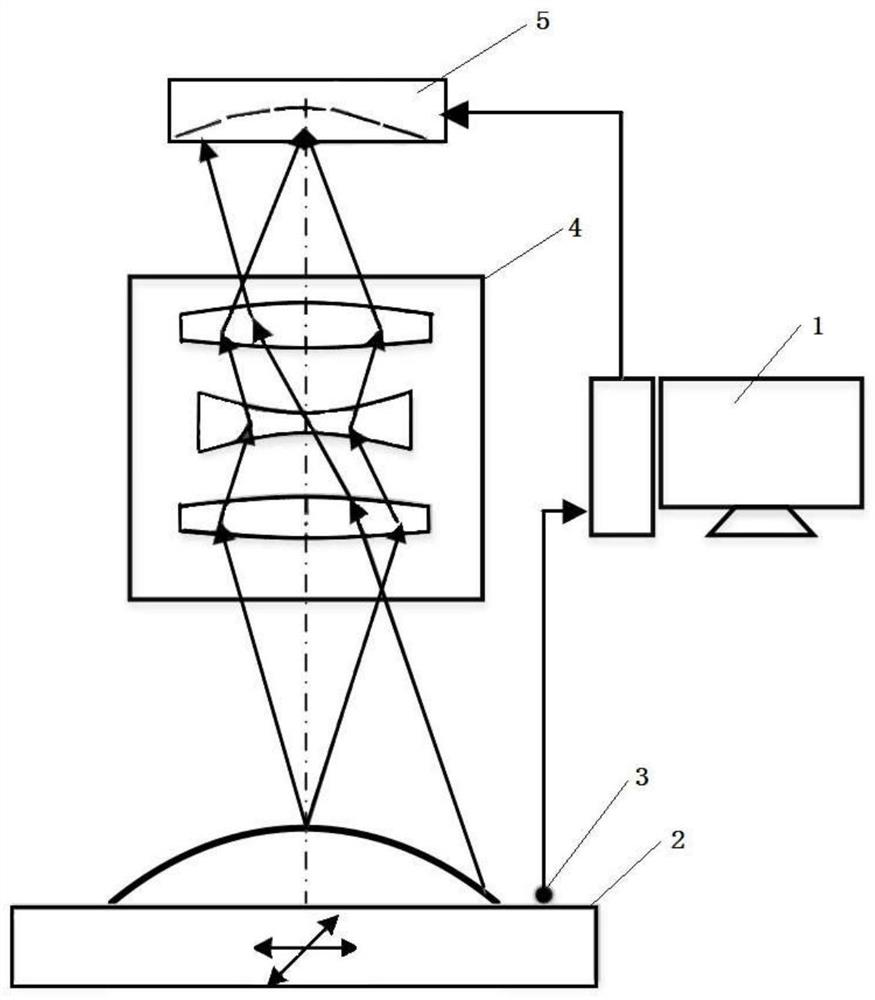

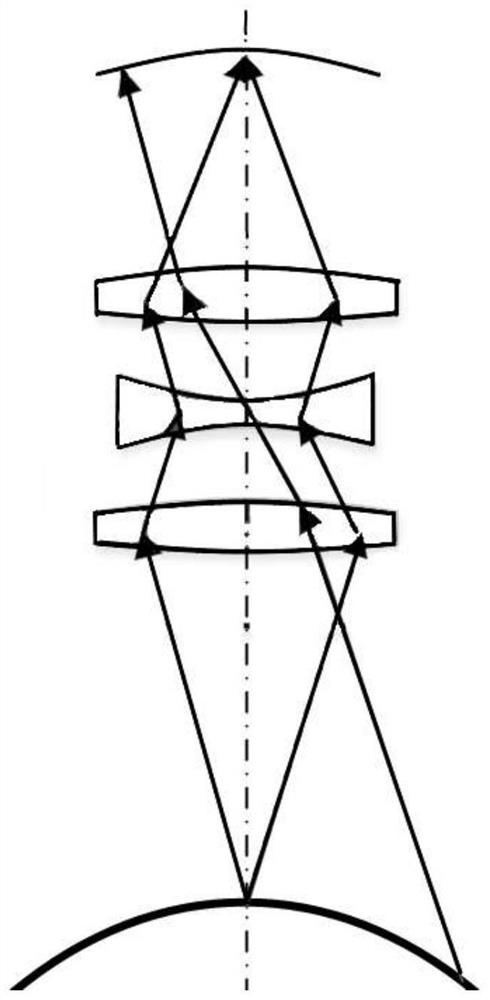

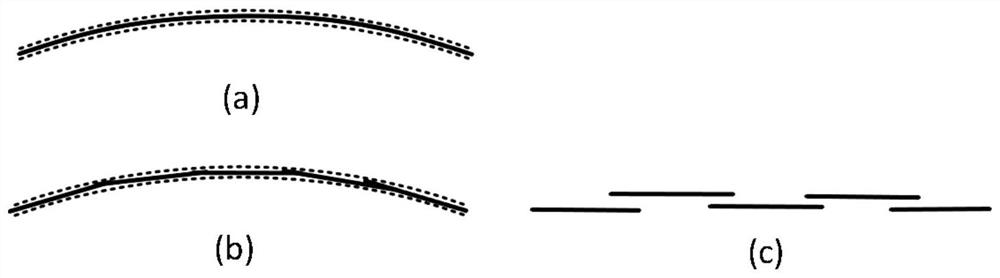

[0030] like Figure 1-2 Shown: the high-resolution curved surface industrial imaging equipment of the present invention includes a computer 1, a curved surface scanning motion subsystem 2, a scanning position sensor 3, an optical lens 4 and a field curvature adaptive linear array detector module 5; the curved surface scanning motion subsystem The system is used to realize the relative movement of its curved surface relative to the optical lens according to the scanning route planned by the computer. The scanning position sensor is used to detect the current scanning position of the curved surface of the curved surface scanning motion subsystem in real time; the computer scans the curved surface of the curved surface scanning motion subsystem in real time. Calculate the position of the curved image plane after passing through the optical lens, and obtain the matching position of each linear array detector in the field curvature adaptive linear array detector module with the curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com