Power plant and power output increase controlling method for power plant

A technology of power generation equipment and control methods, which is applied in the direction of controlling water supply, mechanical equipment, lighting and heating equipment, etc., can solve the problems of equipment cost increase and equipment cost increase, and achieve the effect of suppressing the increase of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, embodiments of the present invention will be described in detail using the drawings.

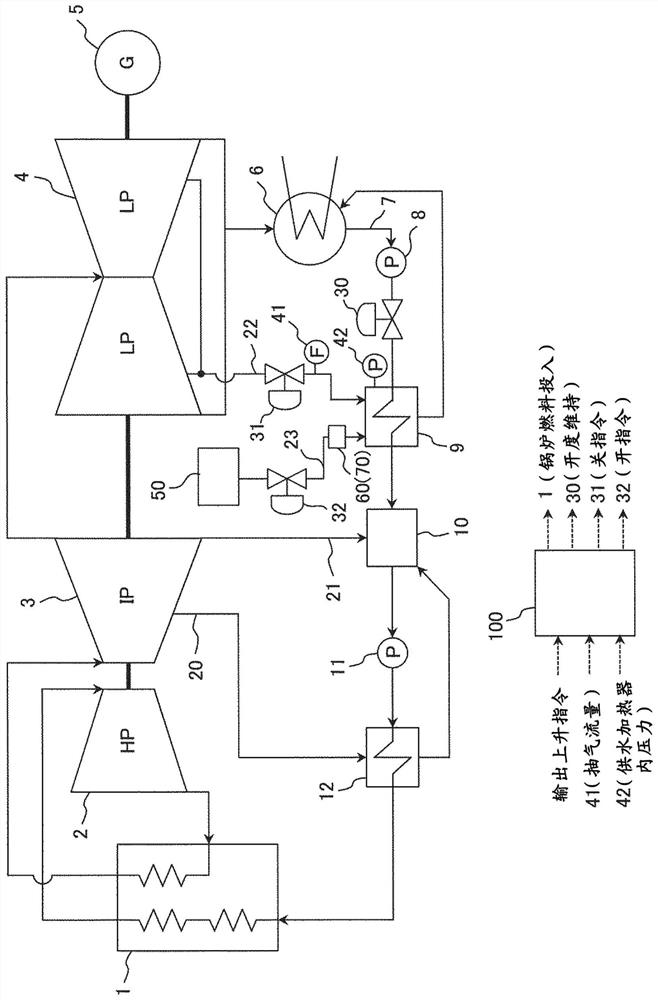

[0012] figure 1 A structural example of the power generation facility of the present invention is shown. In addition, illustration of valves such as a main steam valve and other auxiliary machines such as a desalination device is omitted in the drawings.

[0013] The power generation facility (steam turbine power generation facility) is composed of a boiler (steam generator) 1, a high-pressure turbine 2 driven by the main steam from the boiler 1, and a steam turbine 2 obtained by reheating the exhaust steam of the high-pressure turbine 2 by the boiler 1. An intermediate pressure turbine 3 driven by reheat steam, a low pressure turbine 4 driven by the exhaust steam of the intermediate pressure turbine, a generator 5 driven by the high pressure turbine, the intermediate pressure turbine and the low pressure turbine. In addition, the power generation facility includes a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com