Chemical production equipment with function of uniformly adding reaction raw materials

A technology for reaction raw materials and chemical production, which is applied in the field of chemical production equipment with the function of uniformly adding reaction raw materials, can solve problems such as limited reaction speed, and achieve the effects of simple structure, convenient use and guaranteed efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

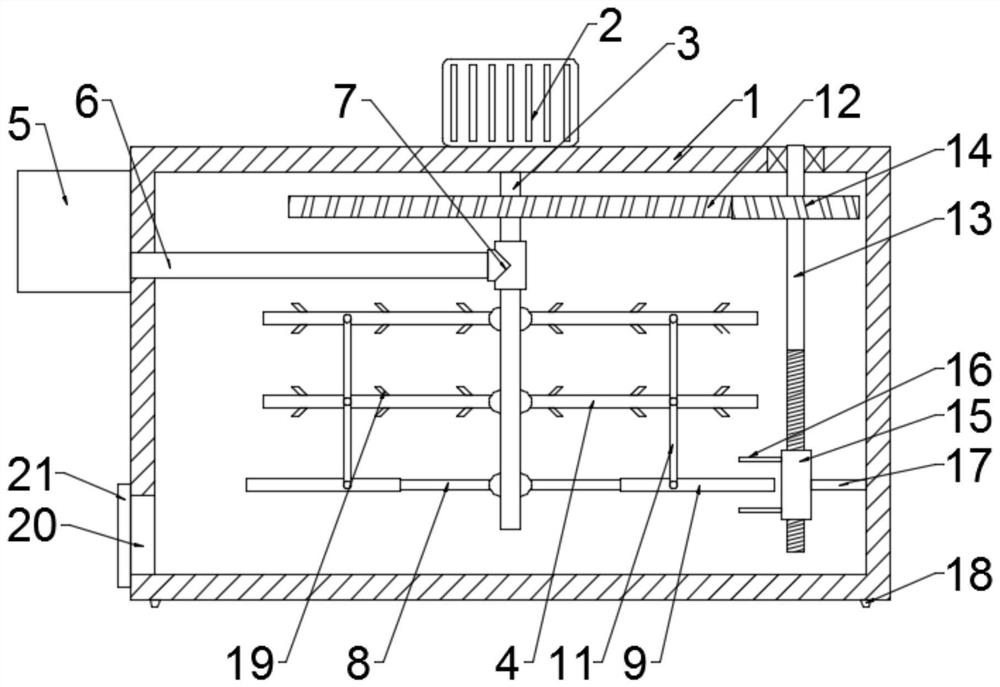

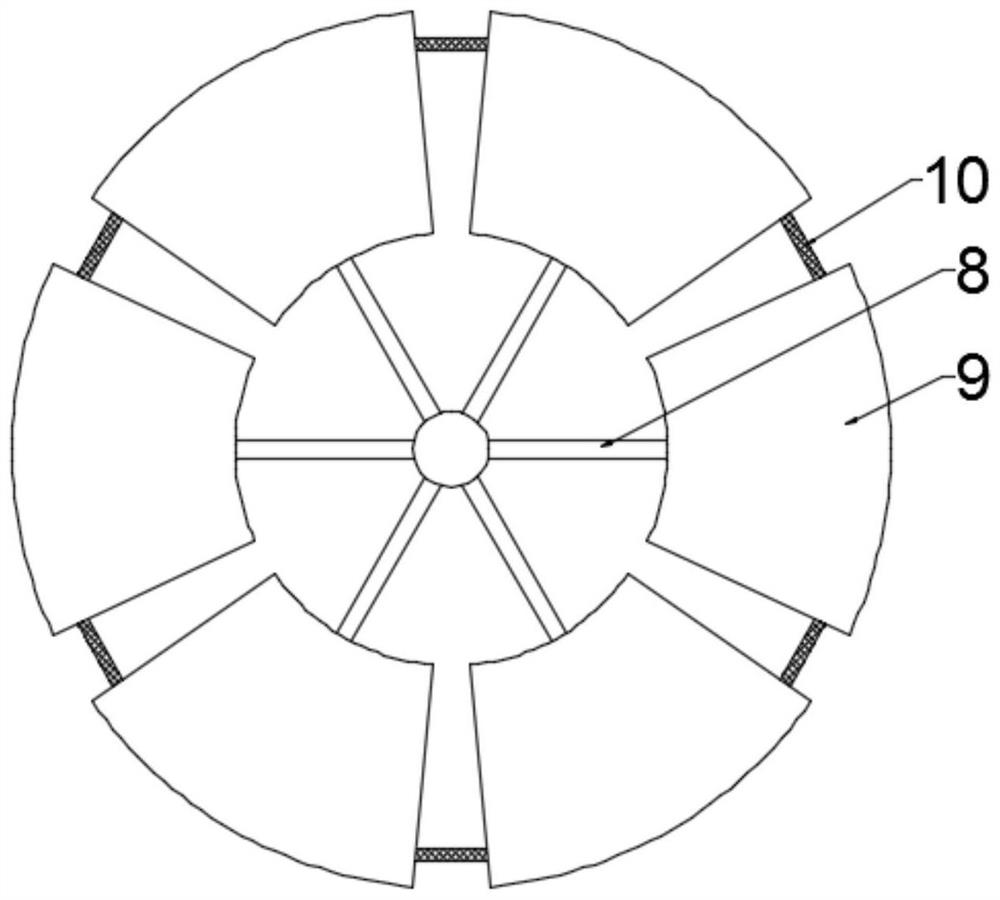

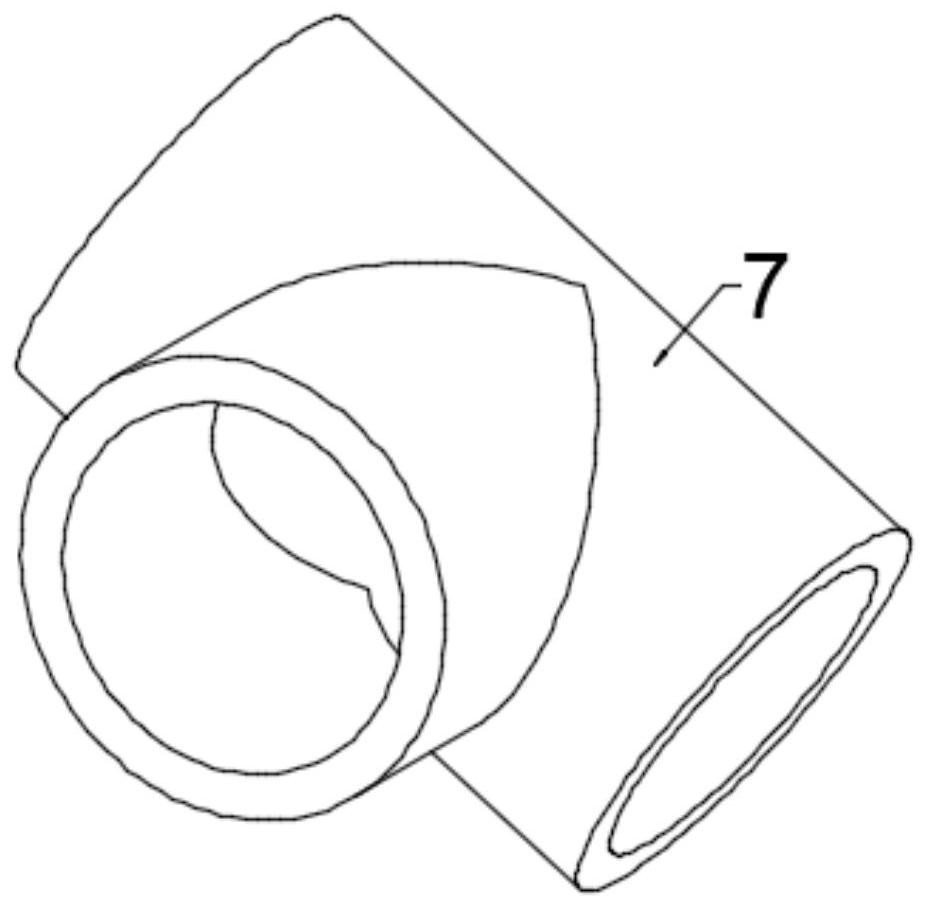

[0022] Example 1: Please refer to Figure 1-4 , a chemical production equipment with the function of evenly adding reaction raw materials, including a reaction box 1, a motor 2 is fixedly connected to the top of the reaction box 1, and a longitudinal rotation tube 3 is fixedly connected to the output end of the motor 2, and the longitudinal rotation tube 3 rotates with the reaction box 1 The vertical rotation pipe 3 is connected with a swing pipe 4 for left and right symmetrical rotation, and the swing pipe 4 communicates with the longitudinal rotation pipe 3 through a flexible pipe. Through 7, the tee 7 is rotationally connected with the longitudinally rotating pipe 3, and the tee 7 is connected with the inner side of the longitudinally rotating pipe 3;

[0023] Turn on the motor 2 when in use, the rotation of the motor 2 drives the rotation of the longitudinal rotation tube 3, the rotation of the longitudinal rotation tube 3 rotates, the rotation of the longitudinal rotation...

Embodiment 2

[0034] Example 2: Please refer to Figure 1-4 , a chemical production equipment with the function of evenly adding reaction raw materials, including a reaction box 1, a motor 2 is fixedly connected to the top of the reaction box 1, and a longitudinal rotation tube 3 is fixedly connected to the output end of the motor 2, and the longitudinal rotation tube 3 rotates with the reaction box 1 The vertical rotation pipe 3 is connected with a swing pipe 4 for left and right symmetrical rotation, and the swing pipe 4 communicates with the longitudinal rotation pipe 3 through a flexible pipe. Through 7, the tee 7 is rotationally connected with the longitudinally rotating pipe 3, and the tee 7 is connected with the inner side of the longitudinally rotating pipe 3;

[0035] Turn on the motor 2 when in use, the rotation of the motor 2 drives the rotation of the longitudinal rotation tube 3, the rotation of the longitudinal rotation tube 3 rotates, the rotation of the longitudinal rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com