Cemented sand and gravel mixing device

A gelled gravel and stone mixing technology, which is applied in the field of mixing methods, can solve the problems of affecting the quality of finished products, splashing, disadvantages, etc., and achieve the effects of improving the quality of finished products, preventing excessive accumulation, and preventing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

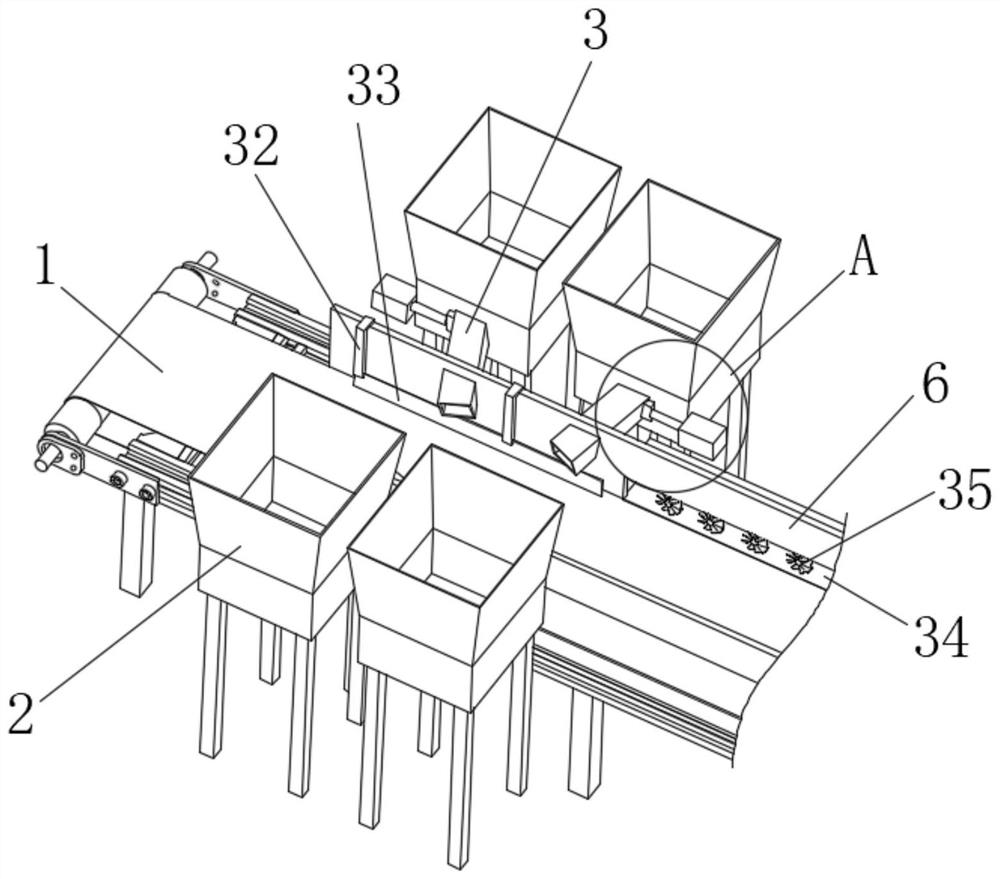

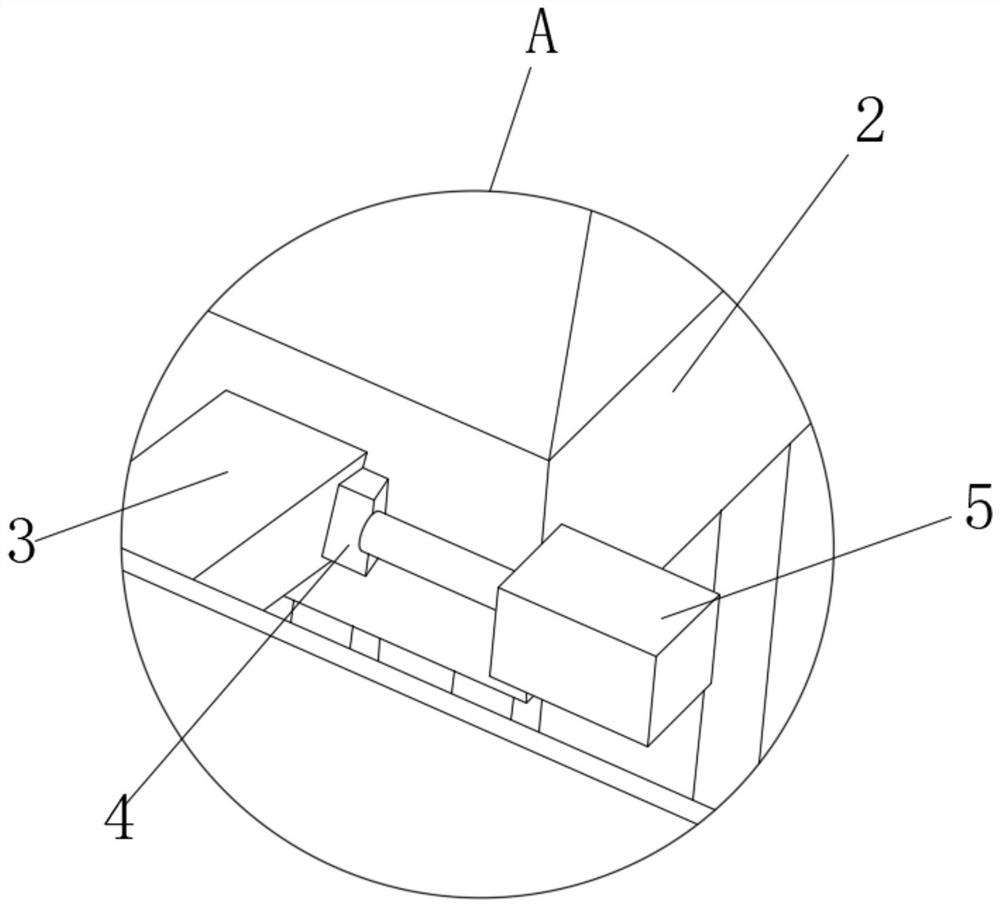

[0026] Such as Figure 1-7 The cemented sand and gravel mixing equipment shown includes a conveyor belt 1 and a control room. Several aggregate hoppers 2 are arranged symmetrically on both sides of the conveyor belt 1. The aggregate hoppers 2 extend close to the outer surface of the conveyor belt 1. Out of the discharge pipe 3, the ends of several discharge pipes 3 extend towards the direction close to each other, the outer surface of the discharge pipe 3 is movably inserted with a blocking mechanism, and the front and bottom of the conveyor belt 1 is fixedly installed with a feeding channel 7, and the feeding One side of the road 7 is provided with an ashes box 8, and the outer surface of the ash box 8 extends over the feeding cylinder 9 above the feeding channel 7, and the inner side of the feeding cylinder 9 is rotated to be equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com