Pipe condition control intelligent irrigation valve, irrigation system and irrigation method

A technology for intelligent control and situation management, applied in control/adjustment systems, non-electric variable control, liquid fertilizer adjustment systems, etc., can solve problems such as pipe rupture or burst, soil structure damage, low water and fertilizer utilization rate, etc., to achieve precise The effect of water and fertilizer irrigation, avoiding tube detachment or bursting, and reducing testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

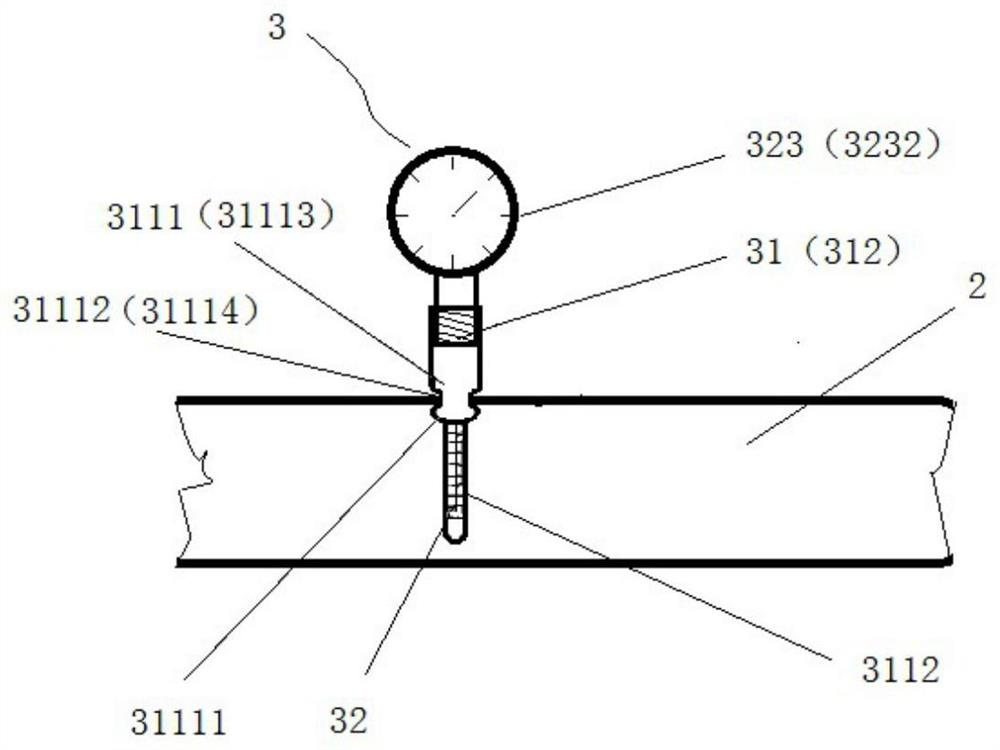

[0031] Pipe condition control intelligent irrigation valve, such as figure 1 and image 3As shown, it includes an electric valve 1, an electric valve opening control device and a pipe situation feedback system. The pipe situation feedback system includes a pipe situation detection device 3 arranged on a water belt hose 2. The pipe situation detection device 3 includes a fixed The sensor housing 31 on the water belt hose 2 and the pipe condition detection sensor 32 extending into the water belt hose 2 through the sensor housing 31; the electric valve opening control device receives the pipe After receiving the fluid information in the pipe from the condition detection sensor 32, the valve opening of the electric valve 1 is comprehensively adjusted according to the preset fluid information, and then the pipe condition feedback control between the hose 2 and the electric valve 1 is realized, and the electric valve 1 is driven. The spool of valve 1 is rotated to the appropriate v...

Embodiment 2

[0034] Different from the above-mentioned embodiments, such as figure 1 As shown, the sensor housing 31 includes a lower housing 311 and an upper housing 312 that are screwed together, and the lower housing 311 includes a pipe-through structure 3111 and a probe protection structure 3112. The probe protection structure 3112 is inserted into the water hose 2 through the side wall of the hose 2, and the sensing element of the pipe condition detection sensor 32 is placed in the filter cavity of the probe protection structure 3112. The pipe-through structure 3111 includes a lower protrusion 31111 and a sealing part 31112. The lower protrusion 31111 is located inside the hose 2 and is connected to the probe protection structure 3112. The sealing part 31112 snaps and seals the The detection hole on the side wall of hose hose 2.

[0035] Preferably, the probe protection structure 3112 includes a cylindrical shell, and the filter cavity is formed by a mesh filter or a strip filter set...

Embodiment 3

[0039] Different from the above-mentioned embodiments, such as figure 2 As shown, the sealing part 31112 includes a sealing tube external thread 31115 arranged above the lower protrusion 31111 and a sealing nut 31116 matching the sealing tube external thread 51115. The side wall of the hose 2 It is clamped between the lower protrusion 31111 and the sealing nut 31116 and seals the detection hole.

[0040] Preferably, the sealing part 31112 includes a sealing pipe external thread 31115 provided above the lower protrusion 31111 and a sealing pipe internal thread provided below the upper housing 312 , the side of the hose 2 The wall is clamped between the lower protrusion 31111 and the upper housing 312 and the detection hole is sealed by screwing the external thread 31115 of the sealing tube and the internal thread of the sealing tube.

[0041] As a preference, a threading hole 313 is provided above the upper accommodating housing 312 for the wired transmission device 3231 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com