High-temperature-resistant explosion-proof camera device with built-in fill-in light

A camera device, high temperature resistant technology, applied in optics, image communication, camera body and other directions, can solve the problem of device overheating, cannot be used normally, high temperature, etc., to achieve the effect of strong practicability, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described further:

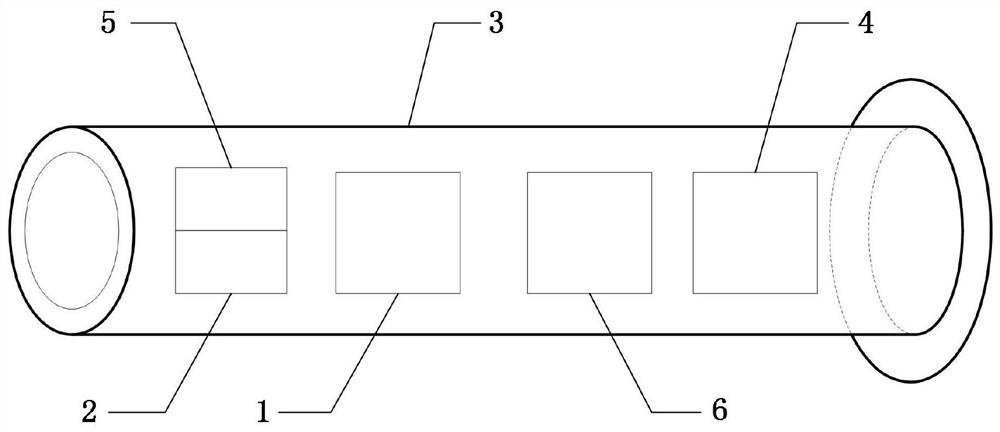

[0011] Such as figure 1 As shown, a high-temperature-resistant explosion-proof camera device with a built-in supplementary light is mainly composed of a core control unit 1, a video unit 2, an explosion-proof unit 3, a semiconductor refrigeration unit 4, an auxiliary light source unit 5, and a communication unit 6. It is characterized in that , the video unit 2 and the auxiliary light source unit 5 jointly complete the video acquisition work, and convert the collected optical signal into a video signal, and the video unit 2 outputs a digital video signal and transmits it to the core control unit 1, and the core The control unit 1 outputs digital signals after processing, and the communication unit 6 outputs the signals to the computer client for display.

[0012] Among them, the explosion-proof unit 3 uses a flameproof explosion-proof shell; the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com