Method, device and equipment for generating order picking task in internal distribution warehouse-out, and storage medium

A distribution and task technology, applied in the field of warehousing and logistics management, can solve problems such as low picking efficiency and excessive picking storage spaces, and achieve the effect of improving picking efficiency and reducing the number of storage spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for generating a picking task during in-house delivery provided in this embodiment is applicable to generating a picking task for an in-house out-of-warehouse operation in a warehouse. The method can be executed by a device for generating picking tasks in the built-in warehouse, the device can be implemented by software and / or hardware, and the device can be integrated in an electronic device installed with a warehouse logistics management system, such as a notebook computer, desktop computer or server etc. see figure 1 , the method of this embodiment specifically includes the following steps:

[0027] S110. When receiving multiple in-stock outbound orders delivered to the same destination warehouse, split each in-house outbound order according to the item category identifier, and generate an outbound order corresponding to each item category identifier in each in-house outbound order. Stock order.

[0028] Among them, the destination warehouse is the deli...

Embodiment 2

[0043] This embodiment further optimizes "generating picking tasks for each target subtask" on the basis of the first embodiment above. The explanations of terms that are the same as or corresponding to the above-mentioned embodiments will not be repeated here. see figure 2 , the method for generating the picking task in the in-house delivery warehouse provided by this embodiment includes:

[0044] S210. When receiving multiple internal distribution outbound orders delivered to the same destination warehouse, split each internal distribution outbound order according to the item category identifier, and generate an outbound order corresponding to each item category identifier in each internally equipped outbound order. Stock order.

[0045] S220. Taking the minimum number of generated target sub-tasks as the goal, split and / or merge each outbound sub-order according to the quantity of items in each outbound sub-order corresponding to the corresponding item category identifie...

Embodiment 3

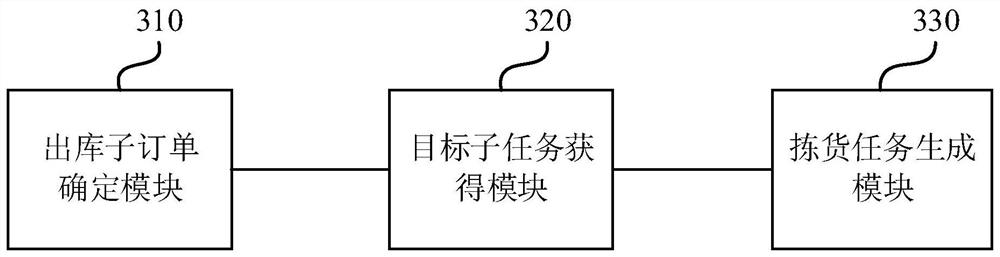

[0060] This embodiment provides a device for generating picking tasks in internal distribution and outbound warehouses, see image 3 , the device specifically includes:

[0061] Outbound sub-order determination module 310, configured to split each internally equipped outbound order according to the item category identifier when receiving multiple internally equipped outbound orders delivered to the same destination warehouse, and generate each internally equipped outbound order Outbound sub-orders corresponding to the item category identifiers in ;

[0062] The target subtask obtaining module 320 is used for merging each outbound sub-order according to the item quantity and the first preset item quantity in each outbound sub-order corresponding to the corresponding item category identifier for each item category identifier, to obtain At least one target subtask; wherein, the quantity to be picked of the target subtask does not exceed the first preset number of items, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com