Efficient oil mist sealing device and sealing method

A sealing device and oil mist technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of safe and stable operation of the unit, increase the flow resistance, and the effect is not significant, and achieve good elasticity and wear resistance , increase sealing performance, prevent static electricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

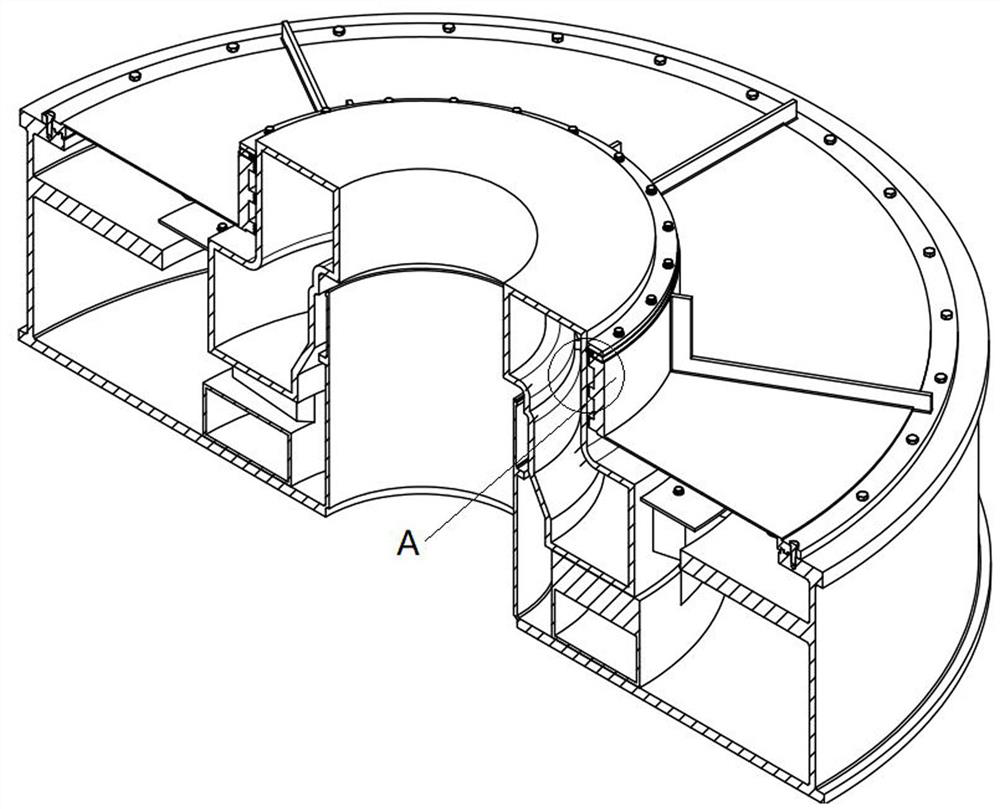

[0025] Below we combine the Figure 1-4 A high-efficiency oil mist sealing device and its use method according to the present invention will be further described.

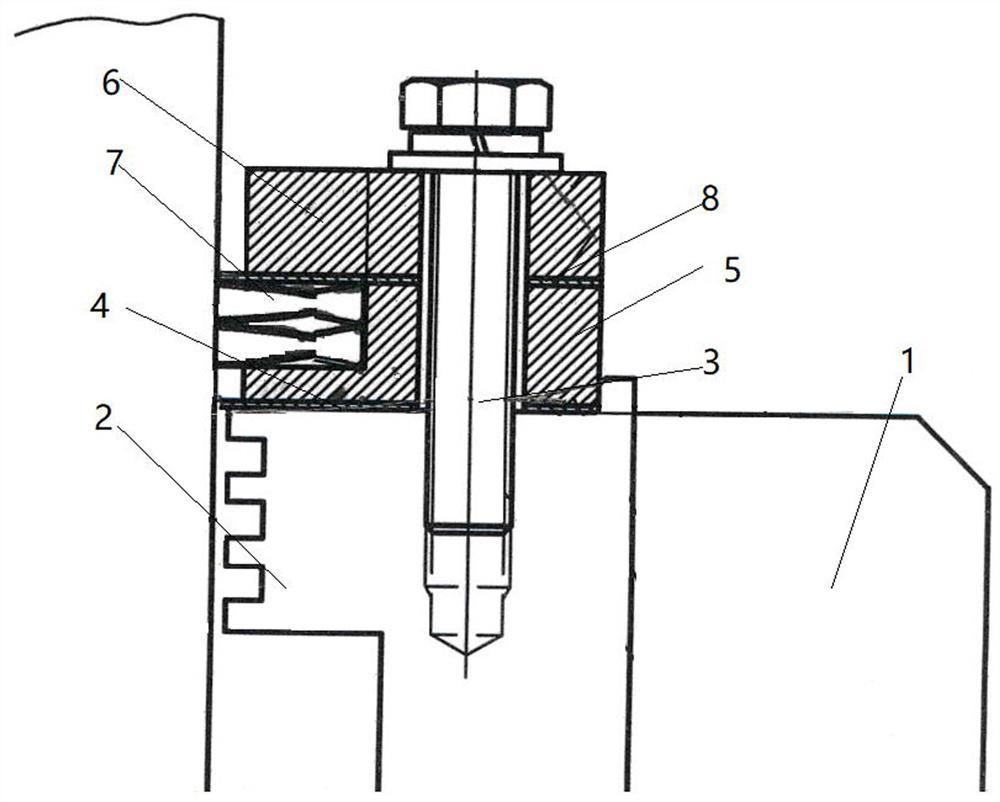

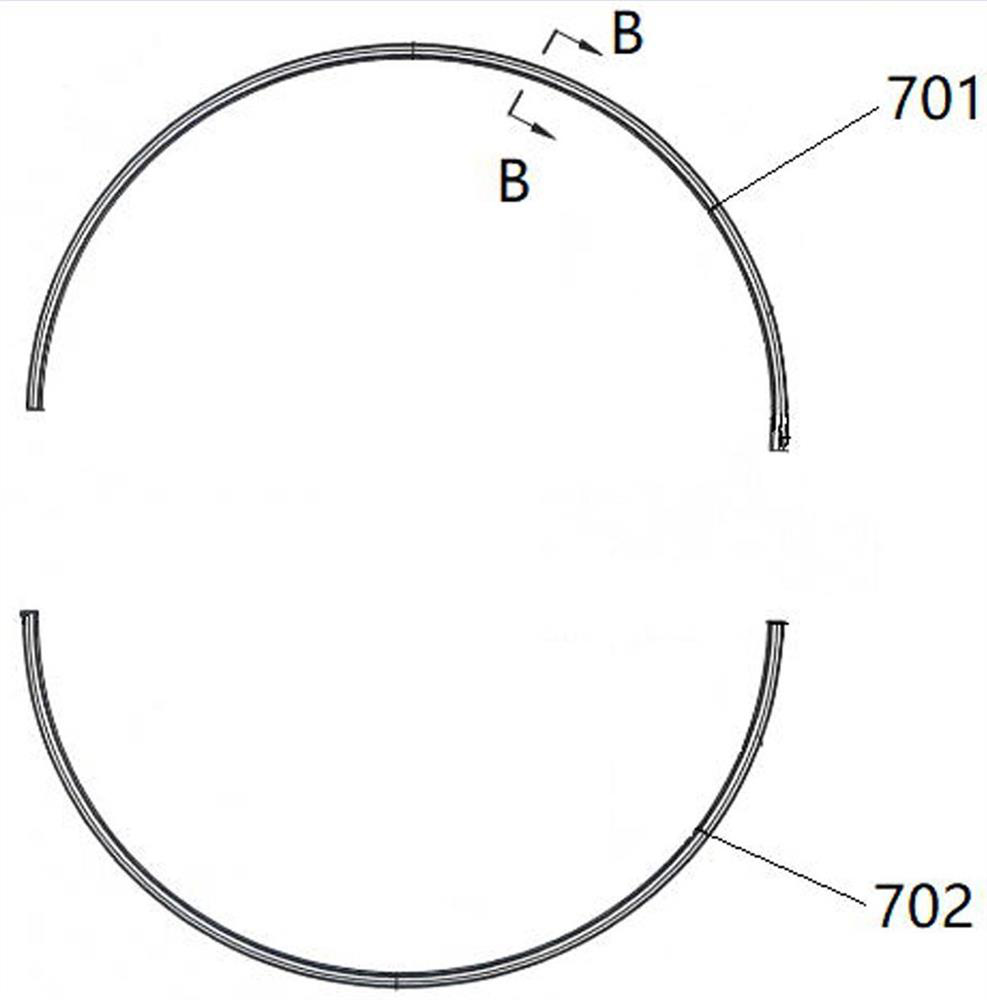

[0026] See attached Figure 1-2 As shown, a high-efficiency oil mist sealing device in this embodiment includes: a bracket 1, a labyrinth seal ring 2 installed on the bracket 1, a gasket 4 installed on the labyrinth seal ring 2, and a seal gasket installed on the gasket 4. Brush seat 5, sealing plate 8 installed on brush seat 5, pressure plate 6 installed on sealing plate 8, sealing brush 7 is installed on brush seat 5, sealing brush 7 includes base 703 and bristle assembly 704 installed on the base , through the non-contact seal of the labyrinth seal ring 2 and the contact seal of the seal brush 7, the oil mist generated during the operation of the equipment can be sealed twice to improve the sealing performance and achieve the purpose of preventing oil mist leakage.

[0027] See attached Figure 2-3 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com