Tailing thickening system and using method thereof

A tailings thickening technology, applied in separation methods, chemical instruments and methods, earth drilling and mining, etc., can solve the problems that the tailings thickening system can only work continuously, cannot be stored, and the rake frame is high, so as to achieve long-term Effects of time storage, storage capacity improvement, and increased mud layer height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

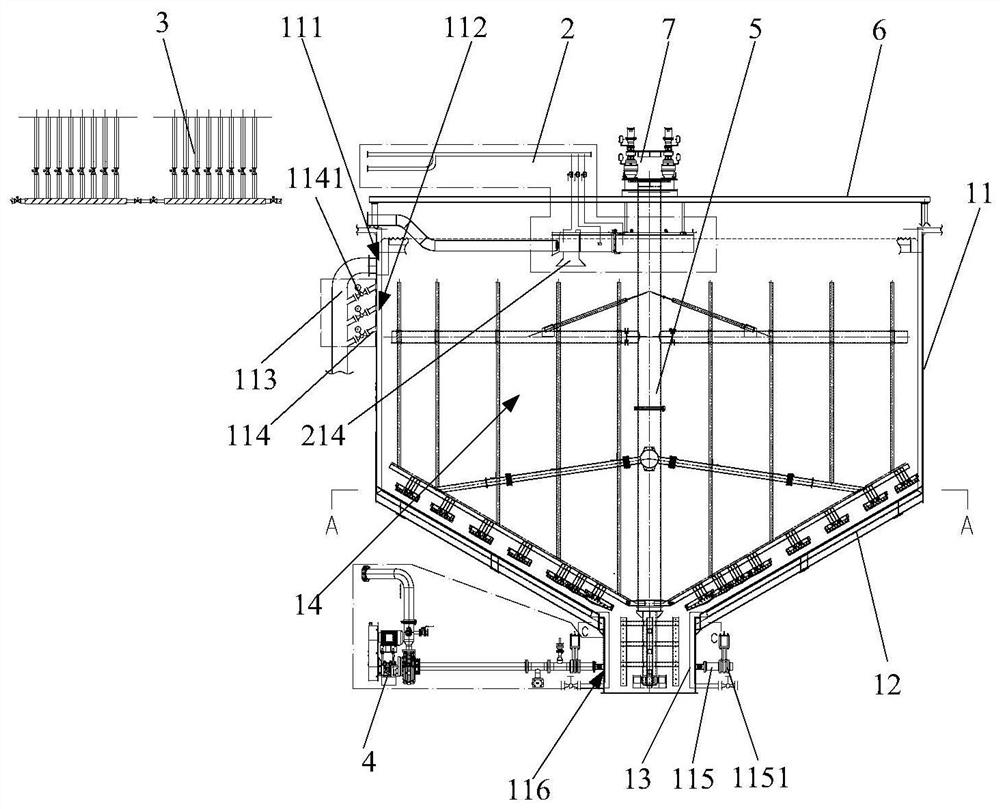

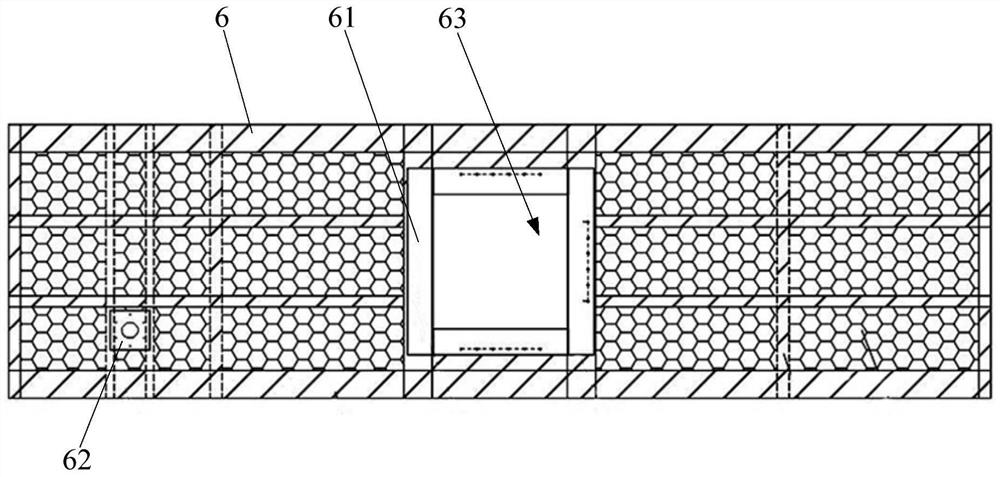

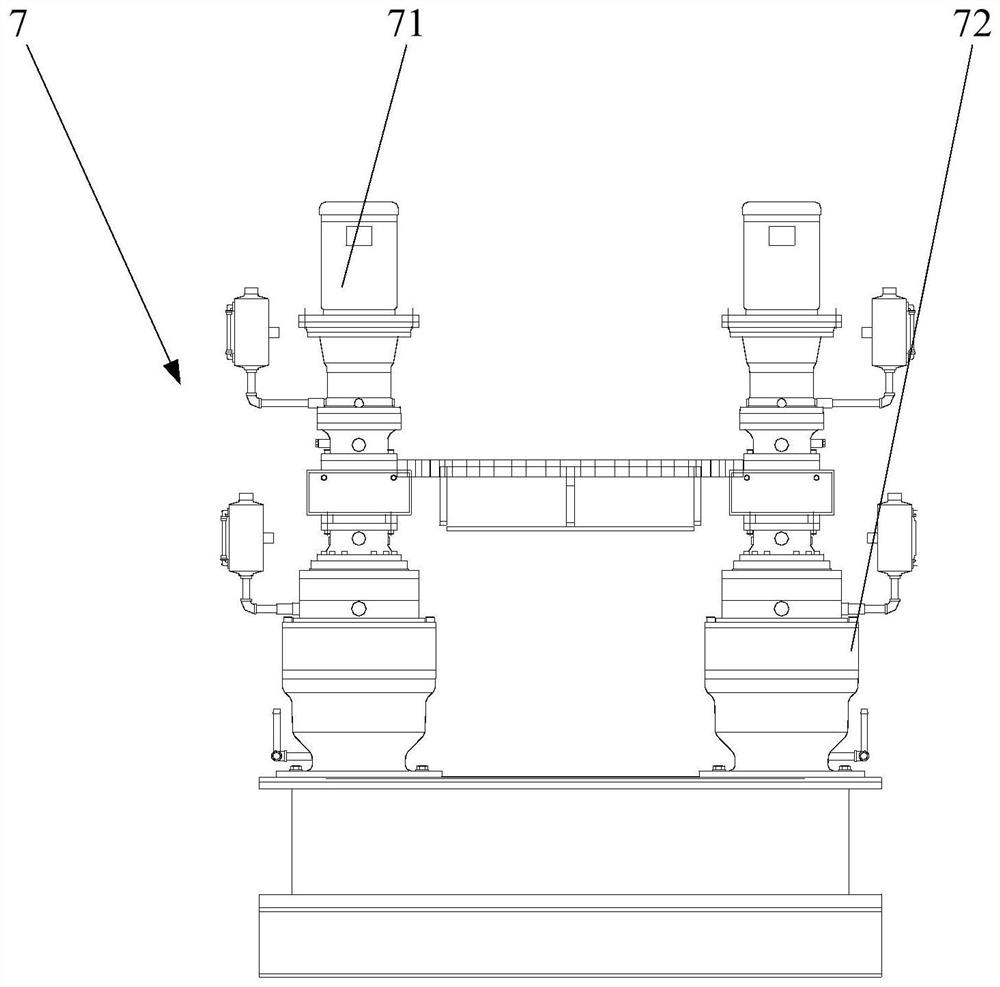

[0074] Such as Figure 1 to Figure 12 As shown, this embodiment provides a tailings thickening system, including: a housing device 1, a feeding device 2, a stirring rake device 5, a driving device 7, a fluidized slurry making device 3 and a discharge device; A housing chamber 14 is formed in the device 1, and the feeding device 2 communicates with the housing chamber 14 for feeding tailings slurry into the housing chamber 14 and dehydrating the tailings; the stirring rake device 5 Set in the accommodation chamber 14 to stir the tailings in the accommodation chamber 14, and shear and compress the tailings flocs; the driving device 7 is connected with the stirring rake device 5, and is used to drive the The stirring rake device 5 rotates; the fluidized slurry making device 3 communicates with the accommodation chamber 14 for fluidizing the tailings in the accommodation chamber 14; the discharge device communicates with the accommodation chamber 14, It is used to discharge the t...

Embodiment 2

[0120] This embodiment provides a method for using the tailings thickening system. Using the tailings thickening system provided in Example 1 includes the following steps:

[0121] S1, the tailings slurry is continuously conveyed to the feeding device 2, and the tailings slurry is conveyed to the accommodation chamber 14 through the feeding device 2;

[0122] Step S1 is preferably that the low-concentration tailings mortar of the dressing plant is connected to the feed port 231 of the mixing tank 23, and the tailings are continuously transported from the feed port 231 into the mixing tank 23 for 24 hours, and the flocculant dosing device 221 will flocculate The flocculant is transported to the flocculant pipeline 222, the flocculant is mixed and diluted with the water entering the dilution pipeline 224, and then enters the mixing tank 23 through the multi-point feeding pipe 223, and the frequency conversion motor 211 drives the stirring blade 212 to rotate, and the accommodatin...

Embodiment 3

[0132] This embodiment provides a method for using the tailings thickening system. Using the tailings thickening system provided in Example 1 includes the following steps:

[0133] S1, the tailings slurry is continuously conveyed to the feeding device 2, and the tailings slurry is conveyed to the accommodation chamber 14 through the feeding device 2;

[0134] Step S1 is preferably that the low-concentration tailings mortar of the dressing plant is connected to the feed port 231 of the mixing tank 23, and the tailings are continuously transported from the feed port 231 into the mixing tank 23 for 24 hours, and the flocculant dosing device 221 will flocculate The flocculant is transported to the flocculant pipeline 222, the flocculant is mixed and diluted with the water entering the dilution pipeline 224, and then enters the mixing tank 23 through the multi-point feeding pipe 223, and the frequency conversion motor 211 drives the stirring blade 212 to rotate, and the accommodatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com