A tcp perforating method

An electronic and switching technology, applied in the field of TCP perforation, can solve the problems of short delay time of gunpowder and accidental perforation accidents, and achieve the effect of strong process applicability, ensuring safety, and avoiding accidental shooting accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments of the present invention and the accompanying drawings. Obviously, the described embodiments do not limit the present invention.

[0027] The technical problem to be solved by the present invention is to make the perforation controllable during the perforation dragging process to avoid false perforation due to the short delay time of the gunpowder, especially how to stop the perforation when a fault occurs during the perforation dragging process , to ensure that there is no accidental perforation accident. In addition, the construction cost of coiled tubing is high. For non-high pressure formations, the use of ordinary tubing to realize the dragging process can reduce the cost of perforating construction.

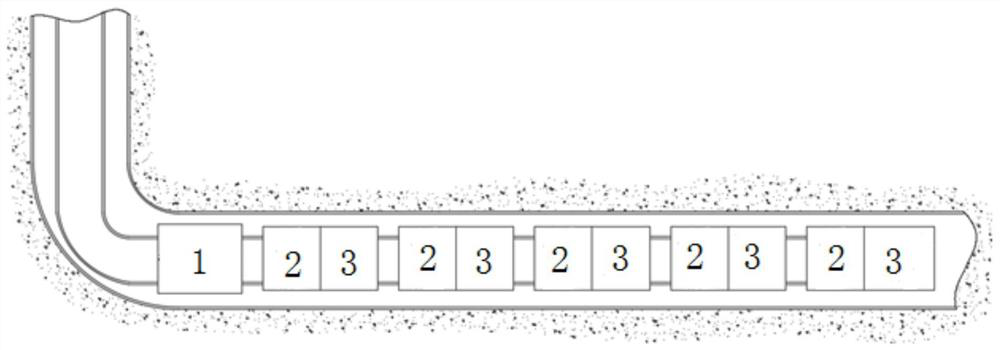

[0028] like figure 1 , to solve the above problems mainly to improve the perforating pipe string down to the well, the pipe string inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com