Three-dimensional knitting machine for carbon fiber preforms

A carbon fiber prefabricated body and weaving machine technology, which is applied in the direction of braided fabrics, textiles and papermaking, to achieve the effect of shortening the production cycle and increasing the weaving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

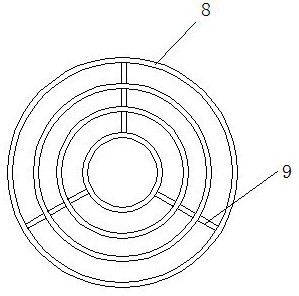

[0027] Embodiment 1: A three-dimensional weaving machine for carbon fiber prefabricated bodies, including a frame 1, the frame 1 includes a base plate and four vertically arranged vertical rods arranged around the base plate on the base plate, and the frame is arranged sequentially from top to bottom Annular disperser 2, orbital disc 3, automatic drive yarn carrier 4, shaper 5, preforming card 6, preforming device 7, annular disperser 2 includes annular rings 8 of different sizes arranged concentrically and connecting annular rings Some struts 9 of 8, the annular ring 8 of annular disperser 2 are annular rings, and the spacing between adjacent two annular rings 8 is equal; On the orbital disc 3, be provided with several circles of threading holes 10, adjacent two The distances between the circle threading holes 10 are equal, the distances between two adjacent circles of threading holes 10 are equal, the number of threading holes 10 in each circle is equal, and the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com