Overhead line system additional line erection traction device

A traction device and catenary technology, applied in the direction of overhead lines, etc., can solve the problems of many construction workers, high risk factor, high labor intensity, etc., and achieve the goal of improving work efficiency, maintaining stable and strong traction force, increasing stability and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

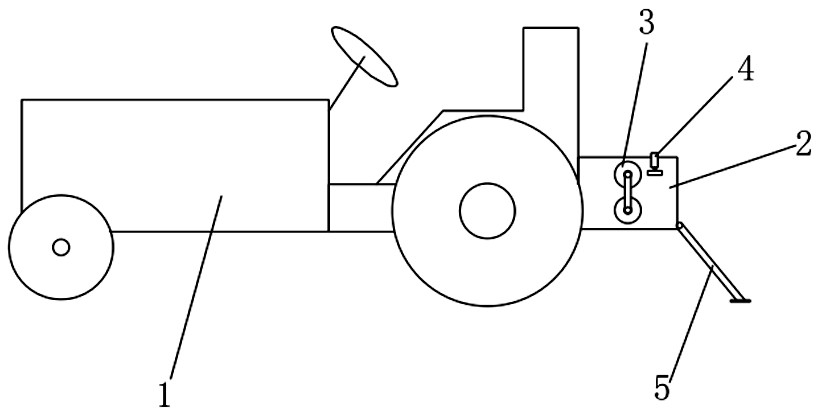

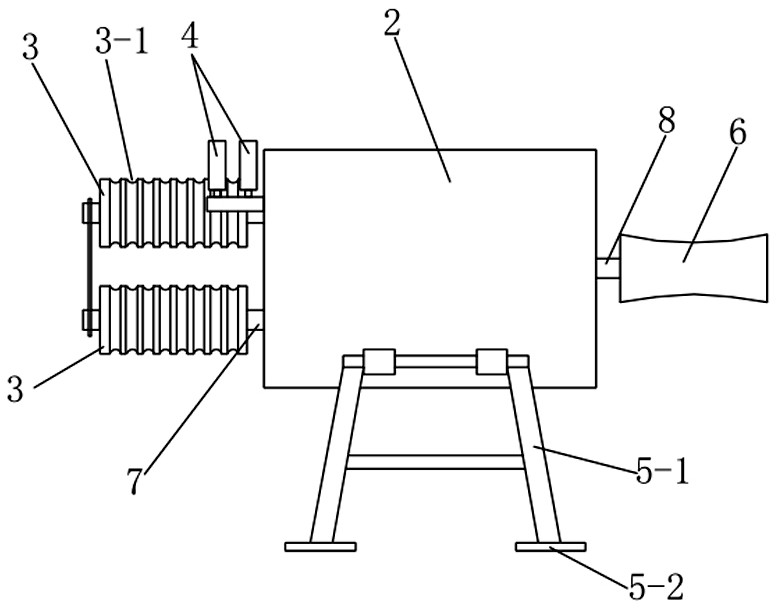

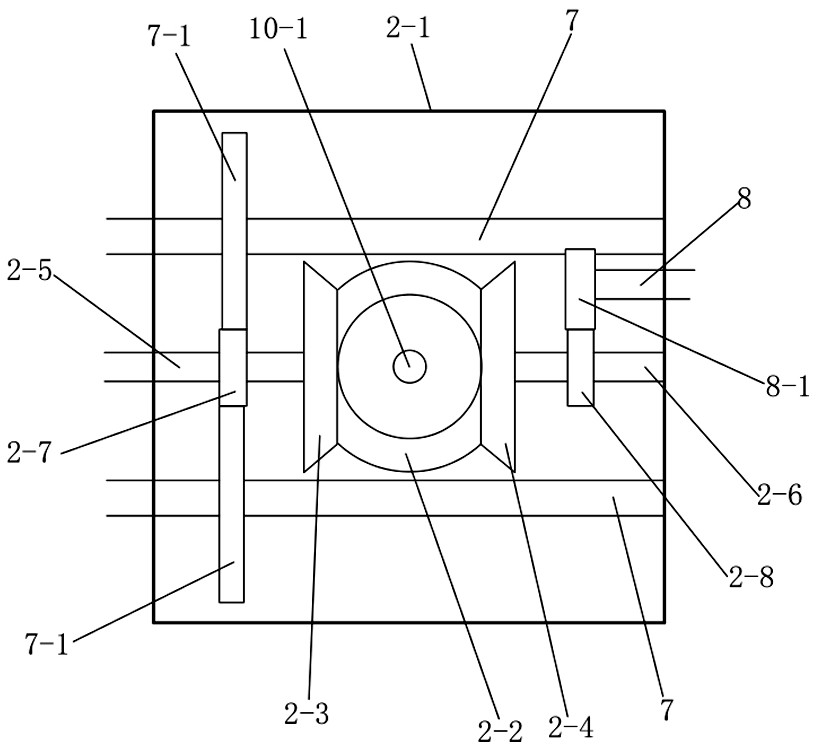

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a tractor 1, a gearbox 2 is arranged at the rear end of the tractor 1, the rear output shaft of the tractor 1 is connected with the power input shaft 9 of the gearbox 2, and a first An output shaft 7, a traction winch 3 is arranged on the first output shaft 7, a second output shaft 8 is stretched out on the other side of the gearbox 2, and a wire winder 6 is arranged on the second output shaft 8, in the transmission Case 2 rear end is provided with anti-reversing support 5.

[0019] Among them, the tractor 1 is a small steering wheel tractor 1 for agricultural use. The small tractor 1 can provide sufficient power, and the driver can easily complete the transfer when the site is changed. The tractor 1 itself has a certain weight and can be more stable during the traction process. .

[0020] There are two traction winches 3, two traction winches 3 are arranged side by side up and down, each traction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com