Preparation method of phosphate adsorbent with high adsorption selectivity

A phosphate adsorbent, selective technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water treatment parameter control, etc., can solve the problems of low adsorption selectivity, phosphorus impurities, etc., and achieve the goal of improving adsorption selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

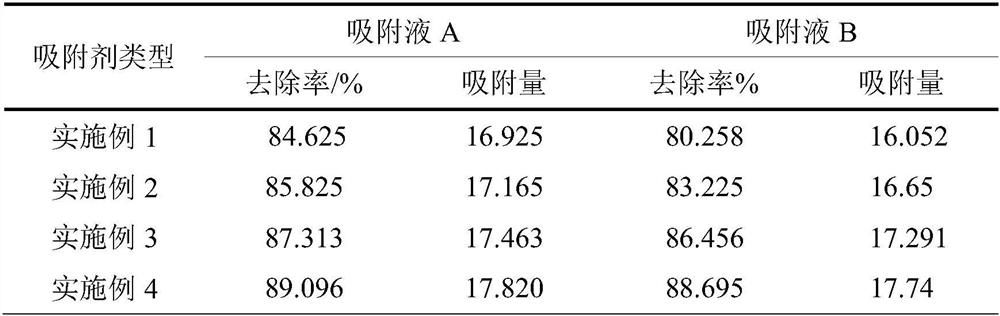

Examples

Embodiment 1

[0020] The preparation method of the high adsorption selectivity phosphate adsorbent of the present invention specifically comprises the following steps:

[0021] (1) Ultrasonic dispersion of modified attapulgite in deionized water to form attapulgite suspension;

[0022] (2) Slowly add humic acid and zirconium dioxide to the attapulgite suspension, the mass ratio of attapulgite, humic acid and zirconium dioxide is 1: 0.3: 0.1; the mixed solution is continuously ultrasonicated for 30 minutes, Then stirred and reacted in a water bath at 70° C. for 2 hours. After the reaction was completed, the obtained mixture was dried in an oven at 110° C. and passed through a 0.074 mm sieve to obtain a mixture A;

[0023] (3) Add a certain amount of polyhydroxyalkanoate into chloroform, and stir slowly. After the polyhydroxyalkanoate is completely dissolved, add mixture A to chloroform, and continue to stir until mixture A is completely dispersed in In chloroform, the addition mass ratio of...

Embodiment 2

[0031] The preparation method of the high adsorption selectivity phosphate adsorbent of the present invention specifically comprises the following steps:

[0032] (1) Ultrasonic dispersion of modified attapulgite in deionized water to form attapulgite suspension;

[0033] (2) Slowly add humic acid and zirconium dioxide to the attapulgite suspension, the mass ratio of attapulgite, humic acid and zirconium dioxide is 1: 0.3: 0.3; the mixed solution is continuously ultrasonicated for 30 minutes, Then stirred and reacted in a water bath at 70° C. for 2 hours. After the reaction was completed, the obtained mixture was dried in an oven at 110° C. and passed through a 0.074 mm sieve to obtain a mixture A;

[0034] (3) Add a certain amount of polyhydroxyalkanoate into chloroform, and stir slowly. After the polyhydroxyalkanoate is completely dissolved, add mixture A to chloroform, and continue to stir until mixture A is completely dispersed in In chloroform, the addition mass ratio of...

Embodiment 3

[0039] The preparation method of the high adsorption selectivity phosphate adsorbent of the present invention specifically comprises the following steps:

[0040] (1) Ultrasonic dispersion of modified attapulgite in deionized water to form attapulgite suspension;

[0041](2) Slowly add humic acid and zirconium dioxide to the attapulgite suspension, the mass ratio of attapulgite, humic acid and zirconium dioxide is 1: 0.4: 0.5; the mixed solution is continuously ultrasonicated for 30 minutes, Then stirred and reacted in a water bath at 70° C. for 2 hours. After the reaction was completed, the obtained mixture was dried in an oven at 110° C. and passed through a 0.074 mm sieve to obtain a mixture A;

[0042] (3) Add a certain amount of polyhydroxyalkanoate into chloroform, and stir slowly. After the polyhydroxyalkanoate is completely dissolved, add mixture A to chloroform, and continue to stir until mixture A is completely dispersed in In chloroform, the addition mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com