Water bath type emulsifying machine for cosmetic production and emulsifying method

A technology of water bath and emulsifier, applied in chemical instruments and methods, mixing methods, mixers, etc., can solve the problems of falling raw materials, insufficient emulsification, poor emulsification effect, etc., and achieve the effect of precise feeding and convenient feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

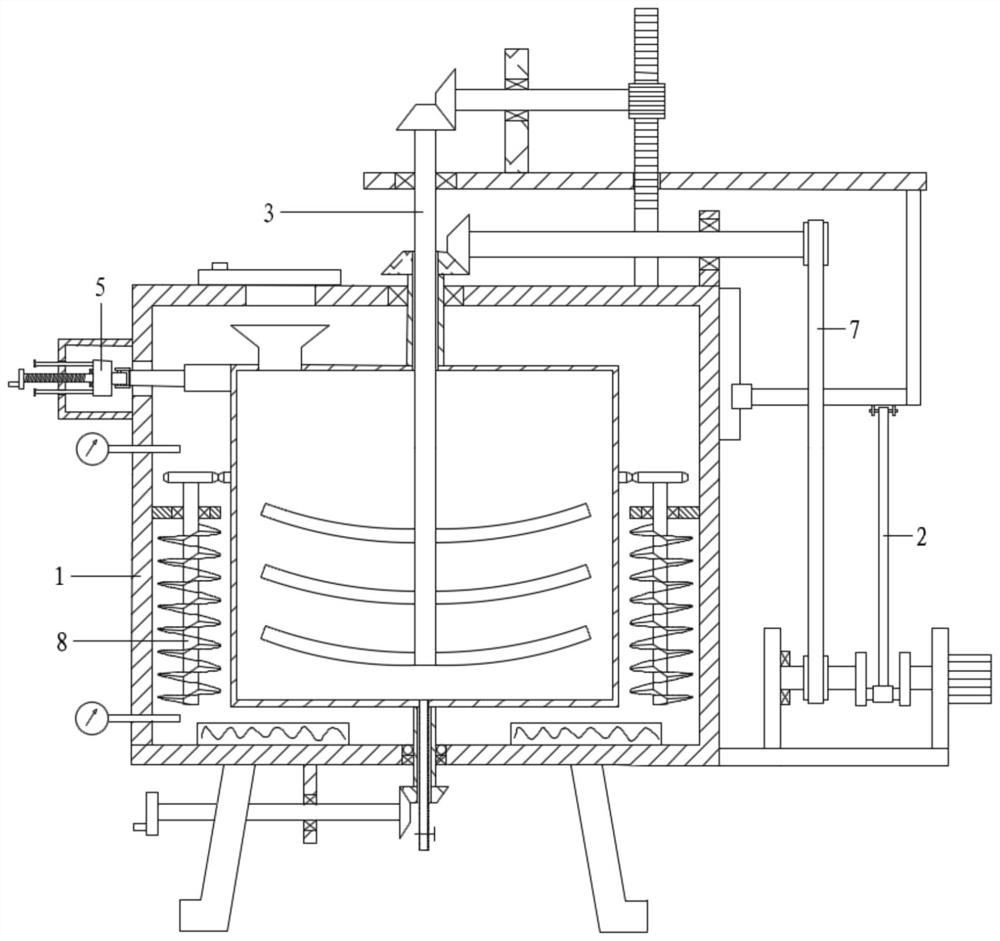

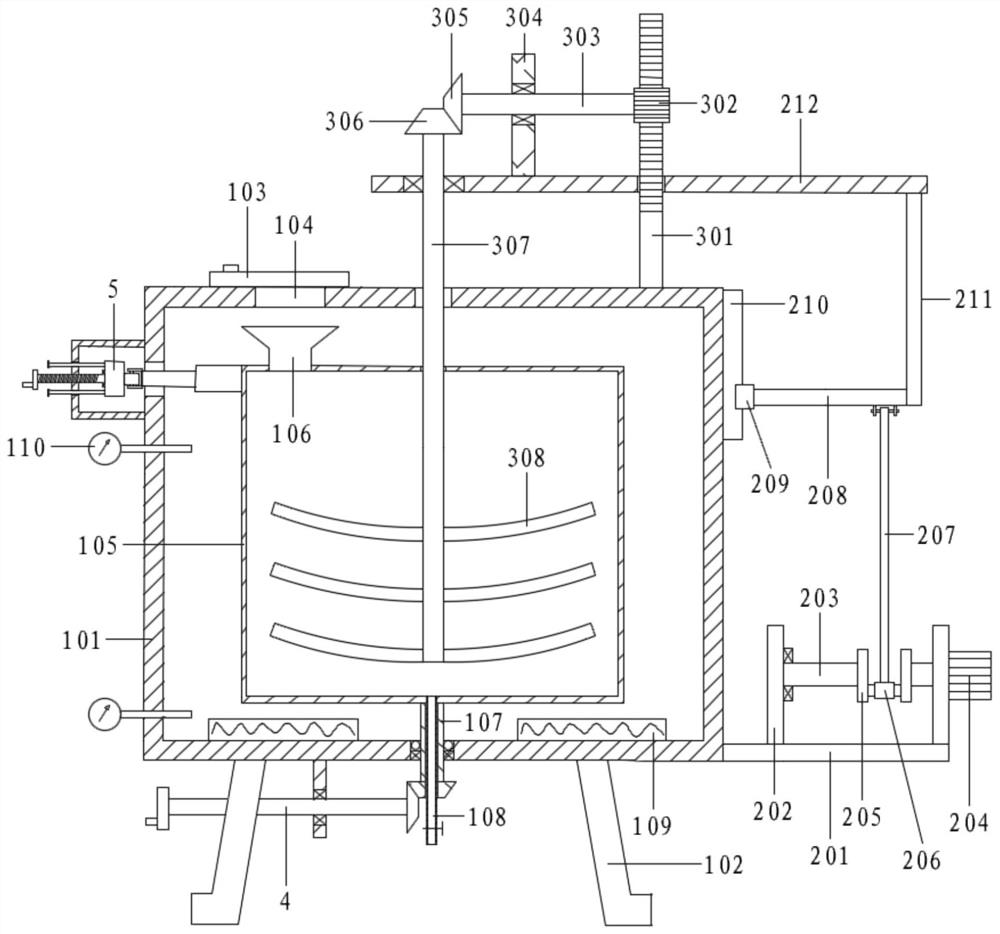

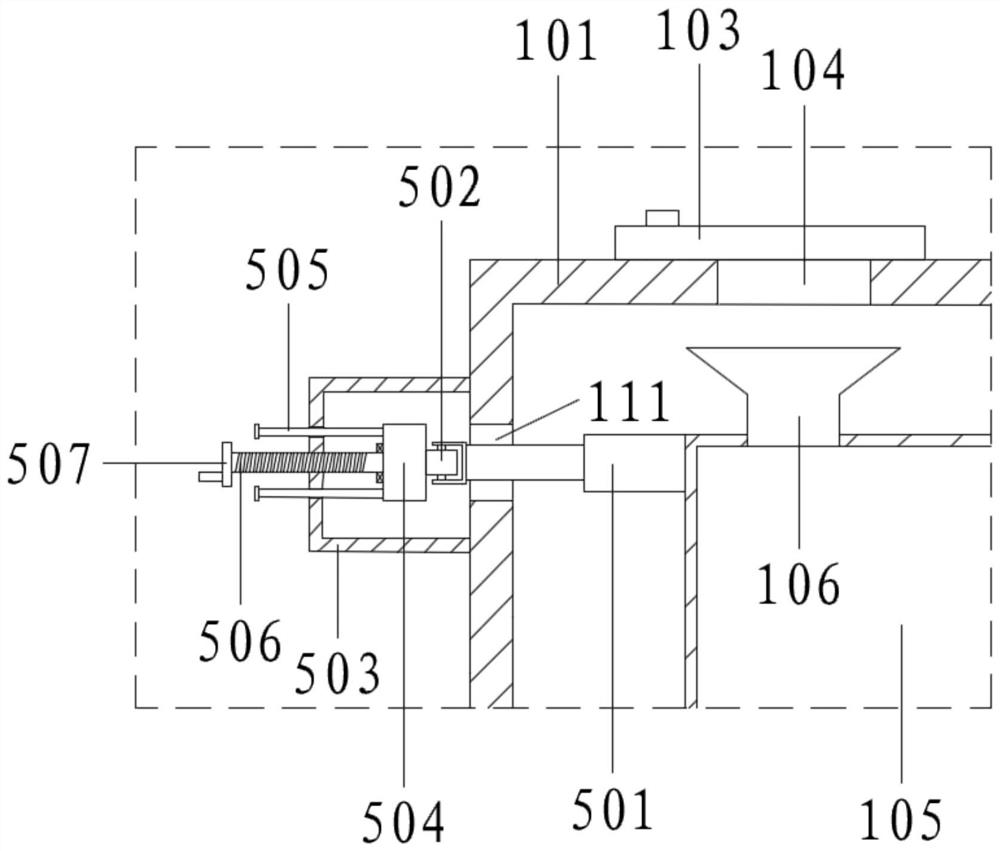

[0059] Referring to the accompanying drawings, a water-bath type emulsifier for cosmetics production includes a tank assembly 1, a lifting assembly 2, an emulsifying assembly 3, a manual adjustment assembly 4, and a positioning assembly 5;

[0060] The tank assembly 1 includes No. 1 tank 101, legs 102, No. 2 tank 105, No. 1 hollow shaft 107, discharge pipe 108, heater 109, thermometer 110 and positioning hole 111; No. 2 tank 105 is arranged on No. 1 tank 101, and set coaxially with No. 1 tank 101; No. 1 tank 101 is equipped with a thermometer 110 at intervals up and down; No. 1 tank 101 is equipped with a heater 109 at the inner bottom; 101 is also connected with water inlet and outlet pipes (not shown), and is equipped with valves for charging or discharging the medium; No. 1 hollow shaft 107 is coaxially connected to the bottom of No. No. tank 101 bottom (the connection is also provided with a sealing ring to avoid water leakage); the bottom of No. 1 hollow shaft 107 protrud...

Embodiment 2

[0062] Referring to the accompanying drawings, a water-bath type emulsifier for cosmetics production includes a tank assembly 1, a lifting assembly 2, an emulsifying assembly 3, a manual adjustment assembly 4, and a positioning assembly 5;

[0063] The tank assembly 1 includes No. 1 tank 101, legs 102, No. 2 tank 105, No. 1 hollow shaft 107, discharge pipe 108, heater 109, thermometer 110 and positioning hole 111; No. 2 tank 105 is arranged on No. 1 tank 101, and set coaxially with No. 1 tank 101; No. 1 tank 101 is equipped with a thermometer 110 at intervals up and down; No. 1 tank 101 is equipped with a heater 109 at the inner bottom; 101 is also connected with water inlet and outlet pipes (not shown), and is equipped with valves for charging or discharging the medium; No. 1 hollow shaft 107 is coaxially connected to the bottom of No. No. tank 101 bottom, (the connection is also provided with a sealing ring, to avoid water leakage); No. 1 hollow shaft 107 bottom extends out ...

Embodiment 3

[0082] On the basis of embodiment 2,

[0083] Also includes rotating assembly 7; rotating assembly 7 includes No. 1 transmission wheel 701, transmission belt 702, No. 2 transmission wheel 703, No. 5 rotating shaft 704, No. 5 support plate 705, No. 5 bevel gear 706, No. 6 bevel gear 707 and No. 2 hollow shaft 708;

[0084] No. 1 transmission wheel 701 is installed on No. 1 shaft 203; No. 5 support plate 705 is fixedly connected to the right end of No. 1 tank 101 top, No. 5 shaft 704 runs through and rotatably connects No. 5 support plate 705; No. 2 shaft 704 is installed on the right end Transmission wheel 703, No. 2 transmission wheel 703 and No. 1 transmission wheel 701 are connected by transmission belt 702; No. 5 bevel gear 706 is fixedly connected to the left end of No. 5 rotating shaft 704; No. 2 hollow shaft 708 is coaxially connected to the top of No. 2 tank 105, No. 2 hollow shaft 708 passes through and connects the top of No. 1 tank 101 through bearing rotation; No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com