A natural gas oven for processing seaweed products and its operating method

A technology of seaweed products and natural gas, applied in separation methods, food ovens, chemical instruments and methods, etc., can solve problems such as easy scorching and uneven temperature, and achieve the goal of improving stability, product quality, and food safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

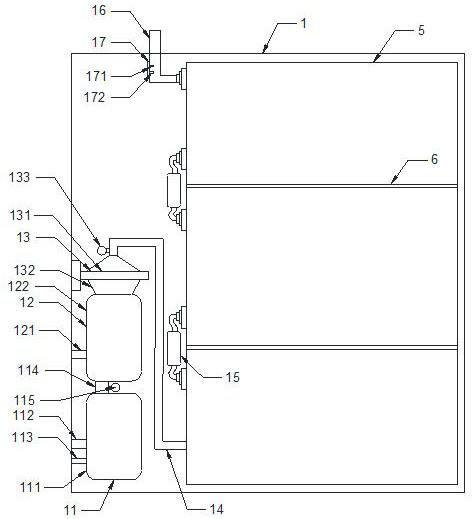

Method used

Image

Examples

Embodiment 2

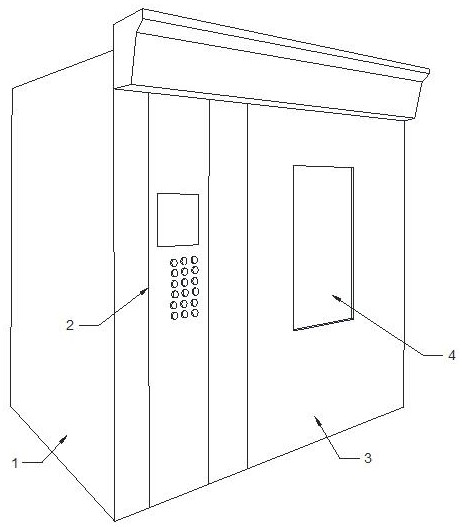

[0052] refer to Figure 6 , this embodiment provides a natural gas oven for processing seaweed products based on the same inventive concept, the difference from Embodiment 1 is:

[0053] The front end of the processing box 5 is not equipped with a processing box door 3, and the rear side of the processing box 5 is not provided with a backboard, and the front and rear lengths of the box body are customized according to the processing requirements, so that the entire equipment can be erected on the assembly line on, so as to achieve continuous processing and handling;

[0054] Because only baffle plate is set before and after, it is an unsealed state, therefore, can set up air pump or fan at the front end or rear end of processing box cooling connection pipe 15, provide power for the airflow in the box;

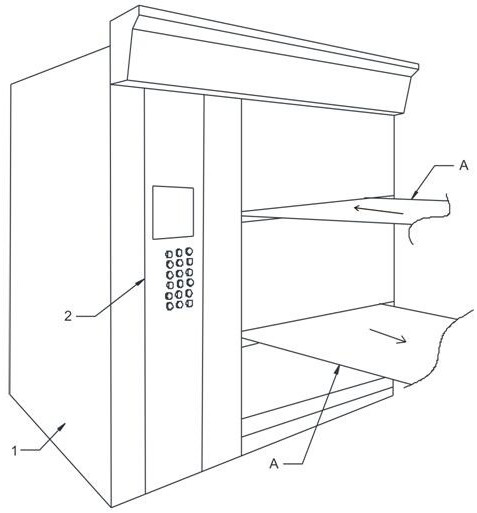

[0055] The conveyor belt exits from the front or rear end of the equipment, and then exits from the opposite end, such as Figure 6 As shown, the conveyor belt is input from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com