Graphene heating film, graphene heating sheet and preparation method thereof

A technology of graphene heating sheet and ene heating film, which is applied in the field of graphene, can solve the problems that limit the wide application of graphene heating sheets, short service life, and inability to fold, and achieve low cost, fast heating speed, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

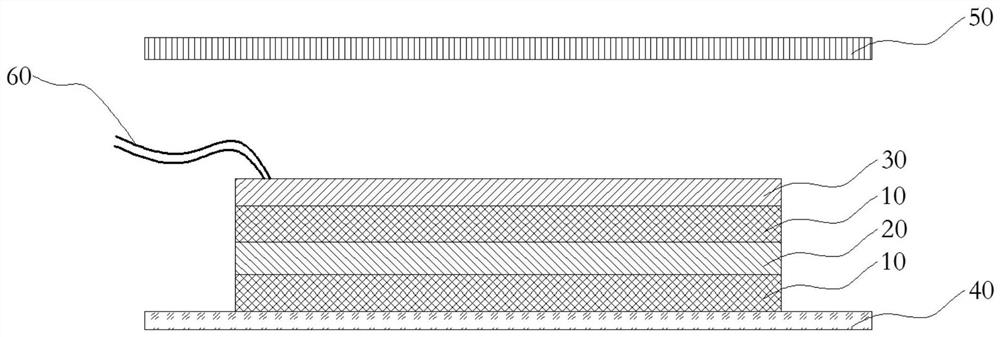

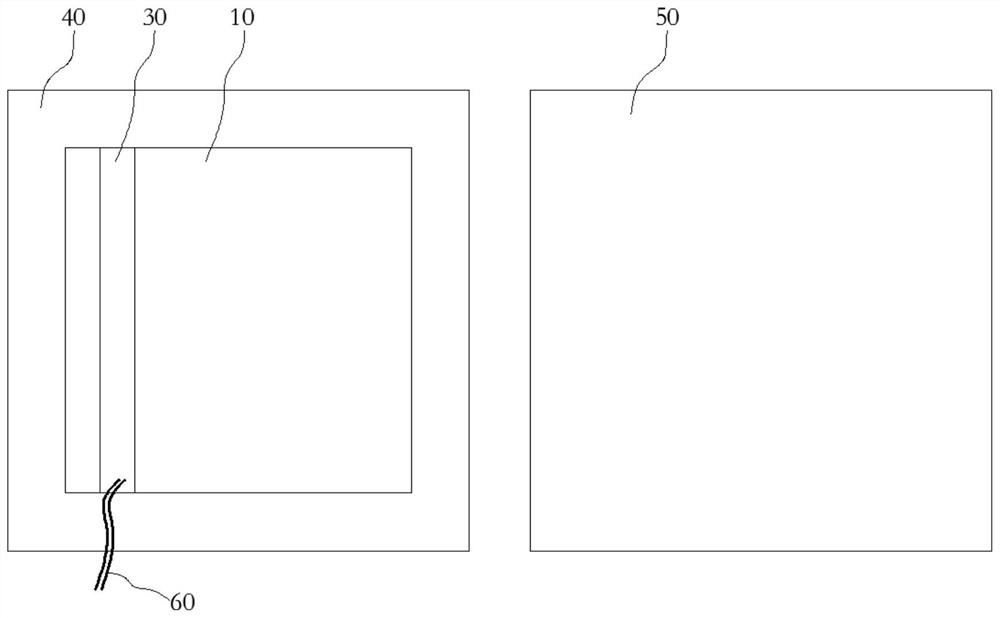

[0025] Such as Figure 1~2 As shown, the present embodiment 1 provides a graphene heating sheet and a preparation method thereof, and the preparation method comprises:

[0026] Add the binder SBR and the dispersant CMC to the solvent, stir, and disperse evenly, then add the tubular carbon material and the sheet-like graphene material, the mass ratio of the tubular carbon material to the sheet-like graphene material is 1:5, stir, Obtain graphene slurry; Wherein, the length of tubular carbon material is 100~200um, the D of tubular carbon material 50 10-30um, the graphene material is single-layer graphene; the weight ratio of binder: dispersant: tubular carbon material and flake graphene material is 3:1:100;

[0027] The graphene slurry is coated on both sides of an aramid fiber layer 20 by coating, and the coating amount of each layer is 0.2ml / cm 2 ;

[0028] drying the solvent, and forming the graphene heating film 10 from the graphene slurry;

[0029] A copper conductor 30...

Embodiment 2

[0032] Add the binder SBR and the dispersant CMC to the solvent, stir, and disperse evenly, then add the tubular carbon material and the sheet-like graphene material, the mass ratio of the tubular carbon material to the sheet-like graphene material is 2:3, stir, Obtain graphene slurry; Wherein, the length of tubular carbon material is 100~200um, the D of tubular carbon material 50 10-30um, the graphene material is single-layer graphene; the weight ratio of binder: dispersant: tubular carbon material and flake graphene material is 5:3:100;

[0033] The graphene slurry is coated on both sides of an aramid fiber layer 20 by coating, and the coating amount of each layer is 1ml / cm 2 ;

[0034] drying the solvent, and forming the graphene heating film 10 from the graphene slurry;

[0035] A copper conductor 30 and a power supply line 60 are provided, the copper conductor 30 is a printed copper layer, which is electrically connected with the graphene heating film 10 and is electric...

Embodiment 3

[0038] Add the binder SBR and the dispersant CMC to the solvent, stir, and disperse evenly, then add the tubular carbon material and the sheet-like graphene material, the mass ratio of the tubular carbon material to the sheet-like graphene material is 5:1, stir, Obtain graphene slurry; Wherein, the length of tubular carbon material is 100~200um, the D of tubular carbon material 5010-30um, the graphene material is single-layer graphene; the weight ratio of binder: dispersant: tubular carbon material and flake graphene material is 4:2:100;

[0039] The graphene slurry is coated on both sides of an aramid fiber layer 20 by coating, and the coating amount of each layer is 0.4ml / cm 2 ;

[0040] drying the solvent, and forming the graphene heating film 10 from the graphene slurry;

[0041] A copper conductor 30 and a power supply line 60 are provided, the copper conductor 30 is a printed copper layer, which is electrically connected with the graphene heating film 10 and is electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com