A kind of conductive fabric/polyaniline composite material electrode and preparation method thereof

A technology of conductive fabrics and composite materials, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, textiles and papermaking, etc., can solve the problem of difficult control of polyaniline growth rate, polyaniline microstructure and loading capacity, difficult to achieve Large-scale production of conductive fabric/polyaniline composite electrodes, etc., to overcome discontinuity defects and avoid uncontrollable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

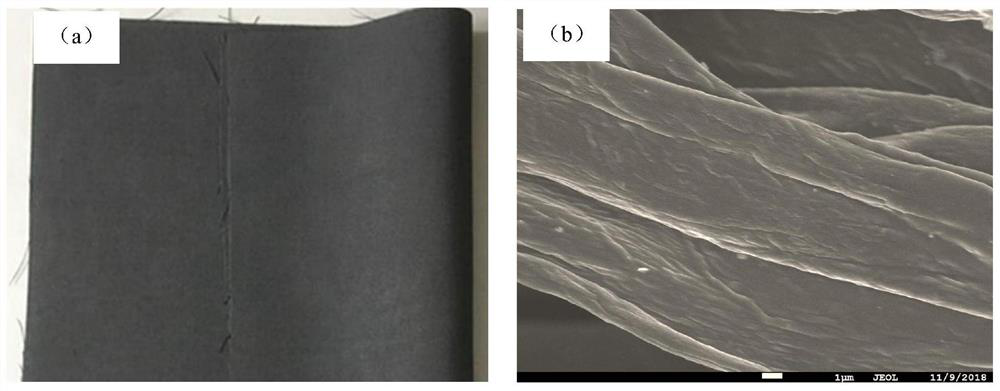

[0028] After the commercialized carbon cloth (W0S1009) was ultrasonically cleaned with deionized water and acetone to remove impurities, the carbon cloth was taken out, washed with a large amount of deionized water until the filtrate was neutral, and dried in a blast drying oven to obtain the pretreated carbon cloth. cloth, its macroscopic and microscopic morphology is shown in figure 1 , (a) is the macroscopic topography figure of the commercialized carbon cloth in Example 1 of the present invention, (b) is the scanning electron microscope image of the commercialized carbon cloth in the Example 1 of the present invention, by figure 1 It can be seen that the carbon cloth is made of carbon fiber, and the surface of the carbon fiber is smooth;

[0029] Add 5 mL of aniline to 10 mL of absolute ethanol and 15 mL of hydrochloric acid (1mol L -1 ) in the mixed solution, recorded as solution A. A certain amount of ammonium persulfate was added to 15 mL of dilute hydrochloric acid (...

Embodiment 2

[0032] The commercial carbon cloth (W1S1009) was ultrasonically cleaned with deionized water and acetone to remove impurities, and then the carbon cloth was taken out, washed with a large amount of deionized water until the filtrate was neutral, and dried in a blast drying oven to obtain the pretreated carbon cloth ;

[0033] Add 5 mL of aniline to 10 mL of absolute ethanol and 15 mL of sulfuric acid (1mol L -1 ) in the mixed solution, recorded as solution A. A certain mass of ammonium persulfate was added to 15 mL of dilute sulfuric acid (1mol L -1 ), recorded as solution B, wherein the molar ratio of ammonium persulfate to aniline was 1.2. The A solution and the B solution were quickly mixed, and placed in an ice-water bath to stand for 20 h. After the reaction, the dark green product was filtered and washed with water until the filtrate was neutral, and the filter cake was dried in a blast drying oven to obtain polyaniline powder. Weigh 30mg of the above polyaniline and...

Embodiment 3

[0036] Commercialized carbon cloth (W0S1002) was cleaned with deionized water and methyl ethyl ketone ultrasonically to remove impurities, and then the carbon cloth was taken out, washed with a large amount of deionized water until the filtrate was neutral, and dried in a blast drying oven to obtain a pretreated carbon cloth;

[0037] Add 4 mL of aniline to 10 mL of absolute ethanol and 15 mL of perchloric acid (1.5 mol L -1) in the mixed solution, recorded as solution A. A certain amount of ammonium persulfate powder was added to 15 mL of dilute perchloric acid (1.5 mol L -1 ) to prepare ammonium persulfate solution, which is recorded as B solution, wherein the mol ratio of ammonium persulfate to aniline is 1.5. The A solution and the B solution were quickly mixed, and placed in an ice-water bath to stand for 24 hours. After the reaction, the dark green product is filtered and washed with water until the filtrate is neutral, and the filter cake is put into a blast drying ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com