Motion control card device for flame cutting numerical control system

A technology of motion control card and flame cutting, applied in general control system, digital control, control/adjustment system, etc., can solve the problems of difficult development, high price, unsuitable for flame cutting numerical control system, etc., to reduce the difficulty of development, Simple inspection and maintenance, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

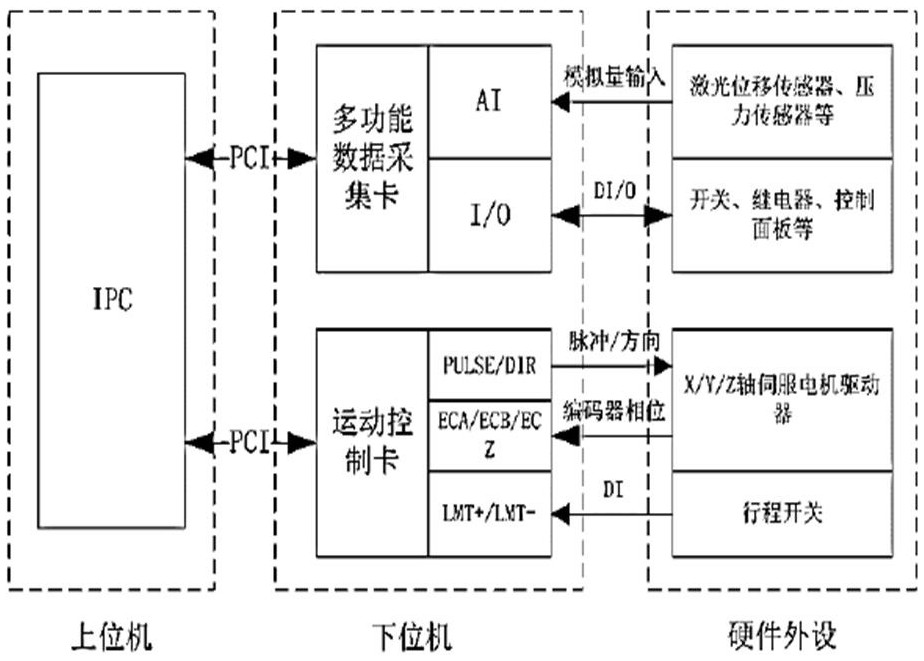

[0015] A motion control card device for a flame cutting numerical control system, comprising: an upper computer IPC, the upper computer IPC is connected to a lower computer through a peripheral component expansion interface PCI, and the lower computer includes a motion control card, the The motion control card has pulse PULSE / direct reduced iron DRI, electronic control amplifier ECA / eddy current braking ECB / comprehensive energy consumption ECZ, local maintenance terminal LMT+ / local maintenance terminal LMT-, the PULSE / DIR is connected through pulse / direction The X / Y / Z-axis servo motor driver, the X / Y / Z-axis servo motor driver is connected to the ECA / ECB / ECZ through the encoder limit, and the X / Y / Z-axis servo motor driver is connected to A travel switch, the travel switch is connected to the LMT+ / LMT-.

Embodiment 2

[0017] The motion control card device for the flame cutting numerical control system described in embodiment 1, the upper computer IPC is used to run the developed numerical control flame cutting system upper computer control software, realizes the communication with the lower computer through the PCI bus , IPC drives the machine tool to complete the cutting process by invoking system resources. At the same time, as the man-machine interface of the CNC system, the IPC has the functions of setting system working parameters, displaying the running status, and tracking the cutting trajectory.

Embodiment 3

[0019] In the motion control card device for the flame cutting numerical control system described in embodiment 1, the lower computer part is mainly composed of two parts: a motion control card and a multi-function data acquisition card; wherein the motion control card outputs pulses and direction signals, Drive the X / Y / Z axis servo motor of the machine tool to interpolate the cutting torch along the processing path, obtain the phase signal of the encoder through the encoder feedback channel, and obtain the actual position of the cutting torch; the DI on the motion control card The channel LMT / LMT‐connected to the state of each limit switch, limits the movement of each axis to ensure that each axis moves within a reasonable range of travel and avoid accidents such as overtravel. The multi-function data acquisition card is mainly composed of two types of analog input channels and DI / O channels. The analog input channels are connected to various analog signal sensors. After A / D c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com