Waste liquid collecting system and method for chemical device

A waste liquid collection and waste liquid technology, applied in pipeline systems, gas/liquid distribution and storage, pipes/pipe joints/pipe fittings, etc., can solve problems such as environmental pollution, achieve the effect of simple and compact structure and improve production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Usually refers to the inside and outside relative to the outline of each part itself; "far and near" usually refers to the distance relative to the outline of each part itself.

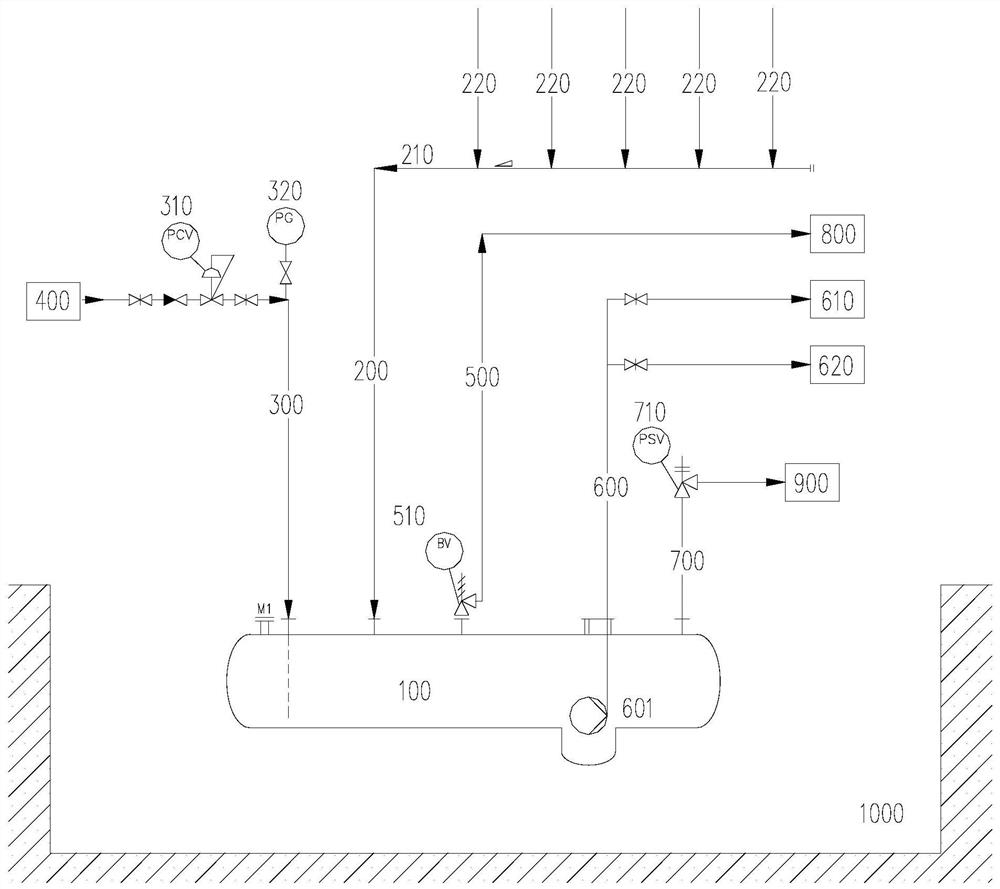

[0030] Such as figure 1 As shown, the present invention provides a chemical plant waste liquid collection system, including a buried waste liquid storage tank 100 arranged in a ground tank 1000 sunk on the ground plane and a waste liquid storage tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com