Wet desulphurization accident slurry system

A wet desulfurization and accident technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems such as the inability of the slurry to be effectively re-injected and reused, the waste of the slurry, and the low utilization rate of water circulation, so as to improve the water circulation. Effectiveness of utilization, prevention of waste, prevention of pressure imbalance in the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

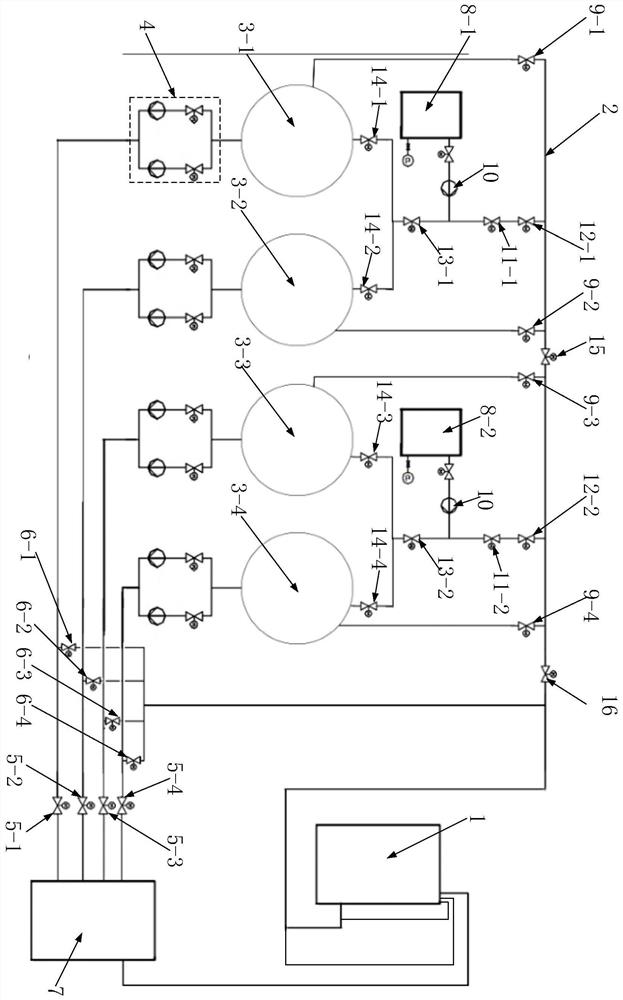

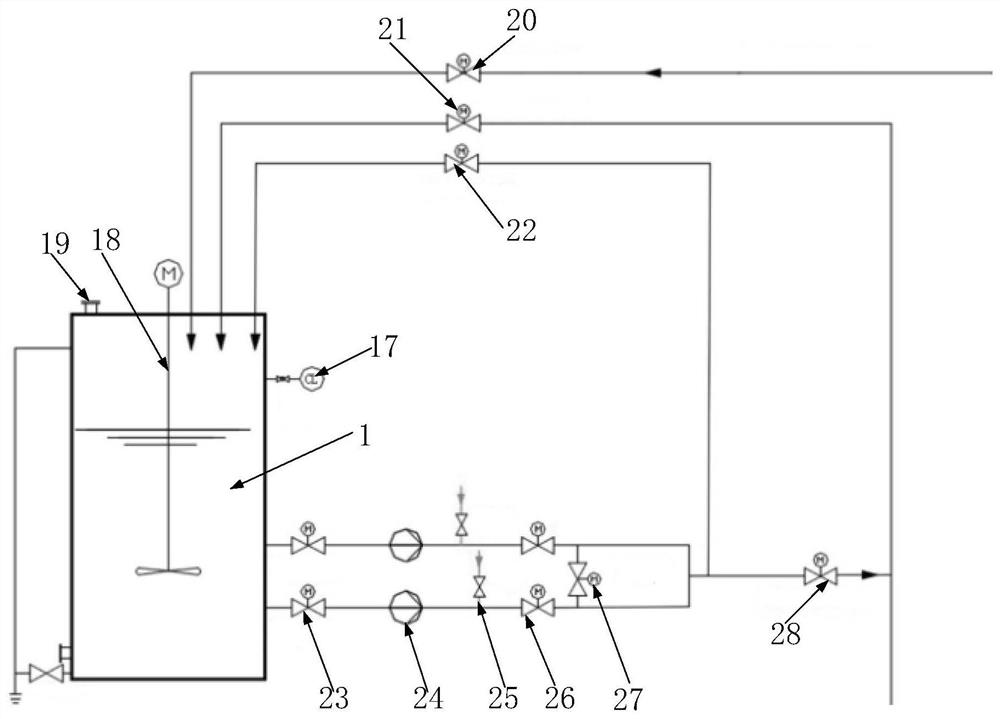

[0030] A wet desulfurization accident slurry system includes an accident slurry recovery component, an absorption tower component, a drainage pit component, a gypsum slurry tank 7 and a main pipe 2.

[0031] The accident slurry recovery component includes the accident slurry tank 1 and the outlet pump group. The liquid inlet of the accident slurry tank 1 is respectively connected with the liquid outlet of the gypsum slurry tank 7 and the main pipe 2 through pipelines, and the liquid outlet of the accident slurry tank 1 is connected through pipelines. The outlet pump group is connected with the main pipe 2. In this embodiment, the liquid outlet of the gypsum slurry tank 7 communicates with the liquid inlet of the emergency slurry tank 1 through the filtrate water recovery main door 20 .

[0032] In this example, if figure 1 , 2 As shown, the outlet pump group includes an accident slurry pump connection valve 27, an accident slurry recirculation door 22, two sets of emergency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com