Wastewater treatment method for lean iron ore sorting factory

A sewage treatment method and sewage technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as waste, save consumption, reduce production costs, and control environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

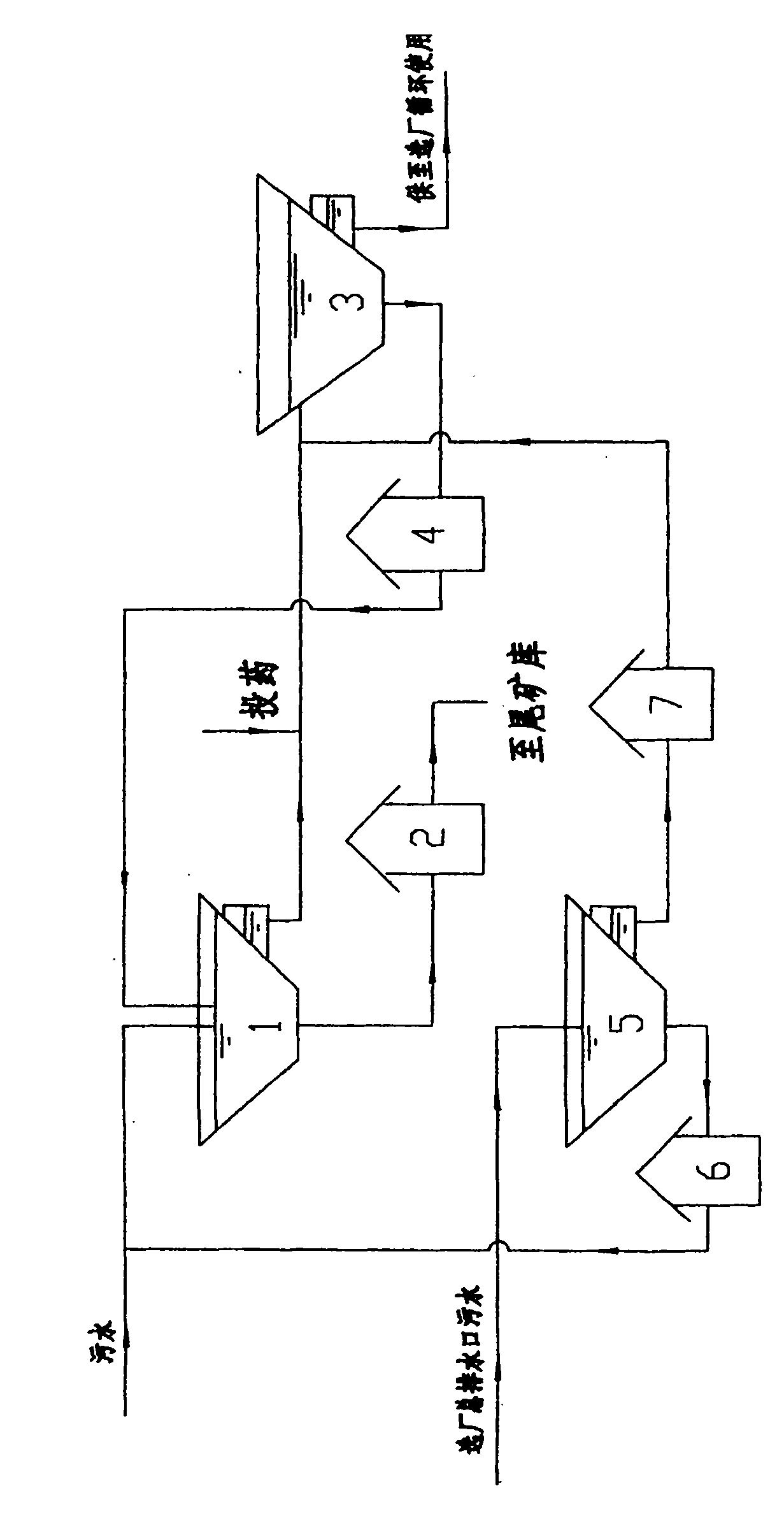

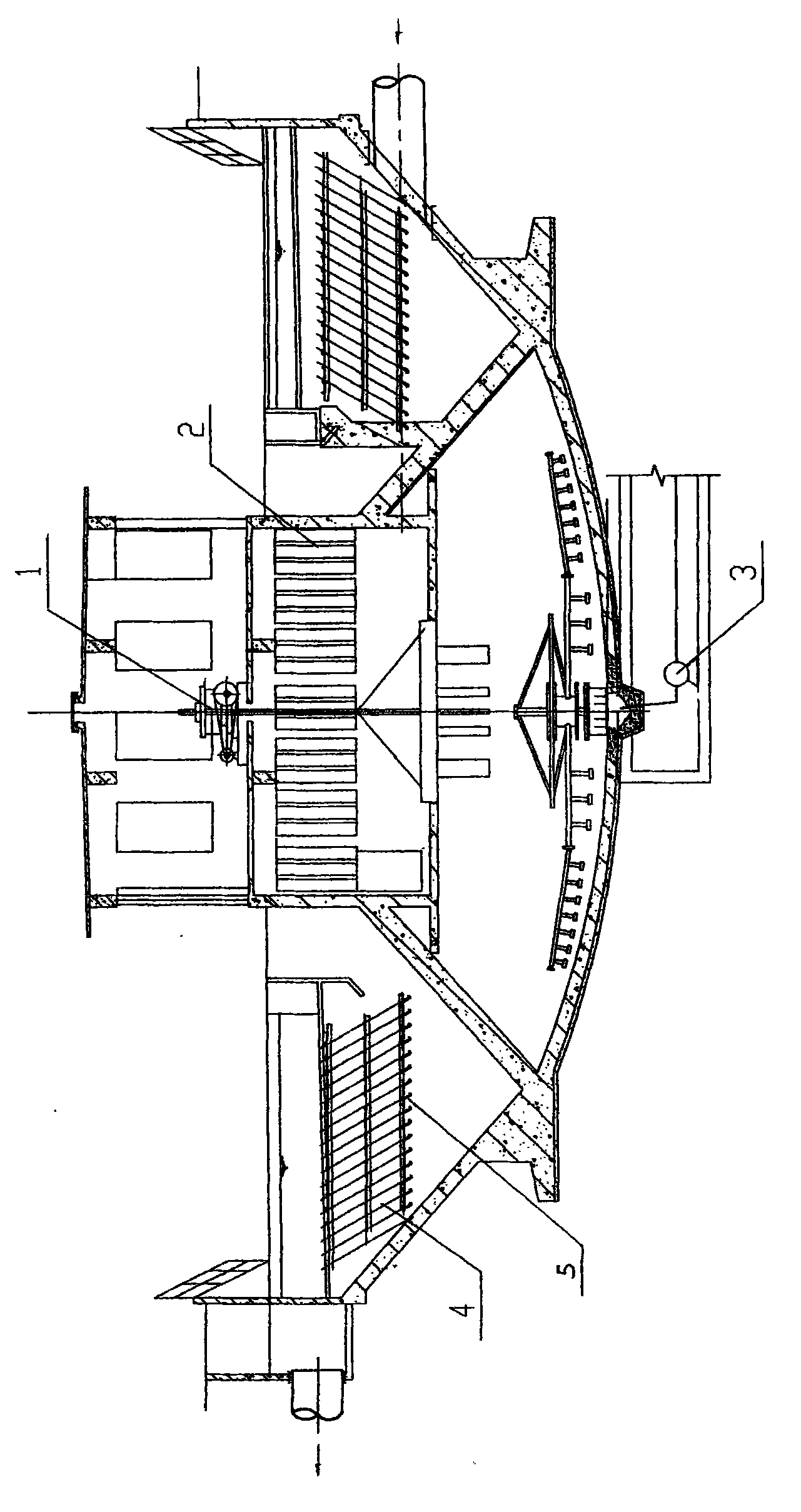

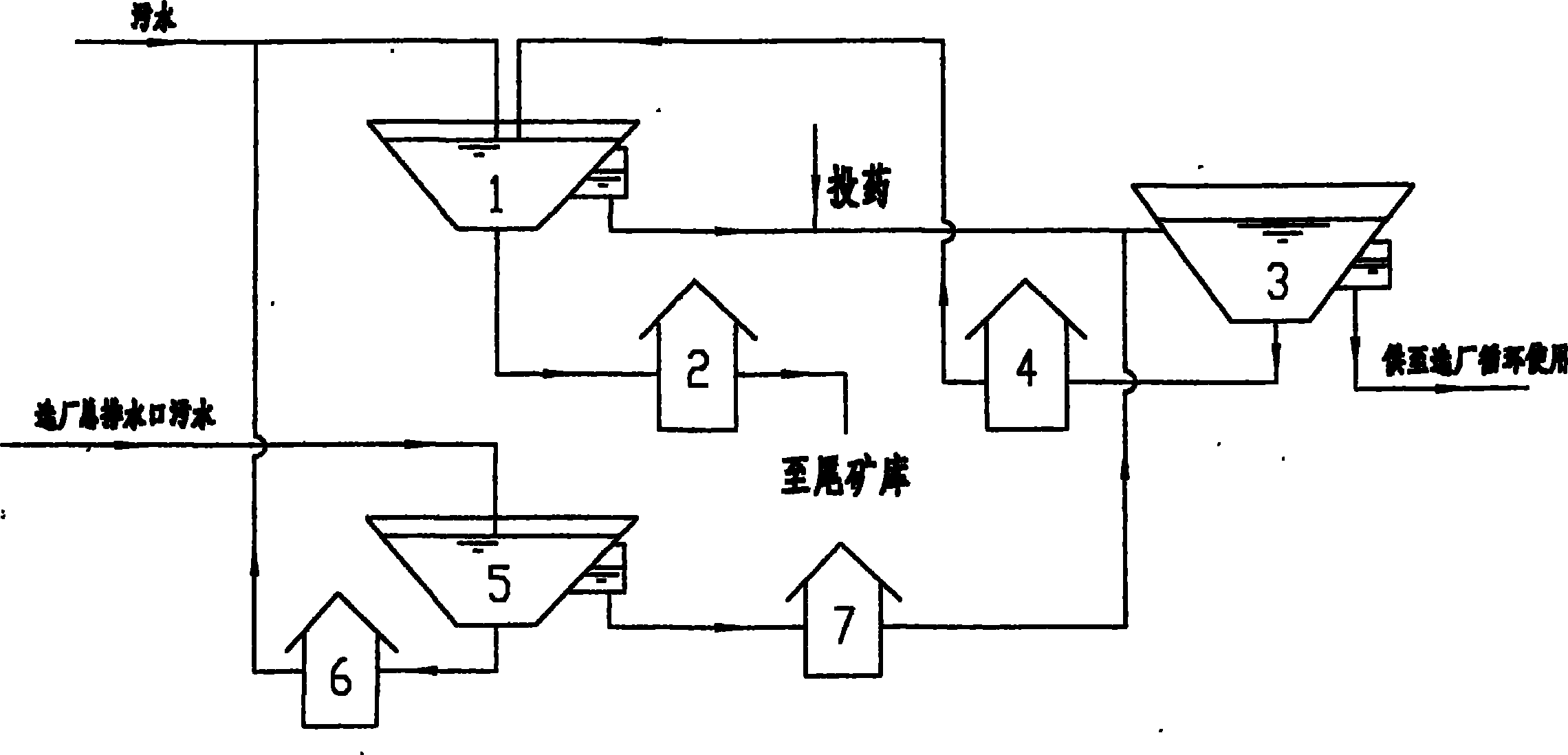

[0016] The waste water treatment method of the abject iron ore dressing plant of the present invention is realized in this way, and is described in detail below. See figure 1 , figure 2 The waste water from the abject iron ore dressing plant passes through the thickening tank 1, and after the bottom flow reaches 45%, it is sent to the tailings pond through the tailings pumping station 2. After the overflow water of the thickening tank is mixed with the chemical agent, it flows into the mechanically accelerated inclined plate clarification tank 3 by gravity. After the sewage is treated, it is sent to the dressing plant for recycling, while the bottom of the clarification tank flows through the bottom flow pumping station 4 and returns to the concentration pool 1 of the dressing plant. After concentration, it is sent to the tailings pond together with the tailings.

[0017] A sedimentation 5 is set at the main outlet of the dressing plant to retain the leaking sewage from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com