Electronic shifter and control method thereof

A technology of electronic shifter and control method, which is applied in transmission control, components with teeth, belts/chains/gears, etc., which can solve the problems of easy touch of arms, unreliable positioning, and occupation of the whole vehicle, etc., to achieve The structure is simple and reliable, and the effect of occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention discloses an electronic shifter and a control method of the electronic shifter. The specific implementation manners of the present invention will be further described below in combination with preferred embodiments.

[0060] The "locking structure", "locking mechanism", "self-locking structure", and "self-locking mechanism" that may be involved in various embodiments of the present invention are the same concept and will not be distinguished.

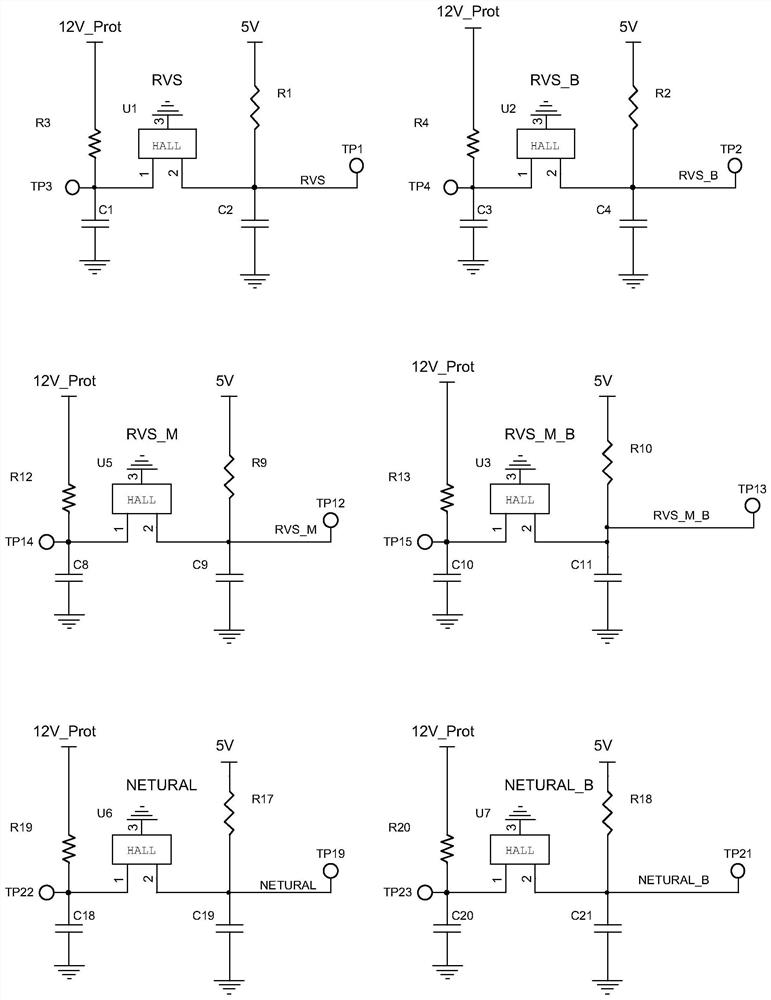

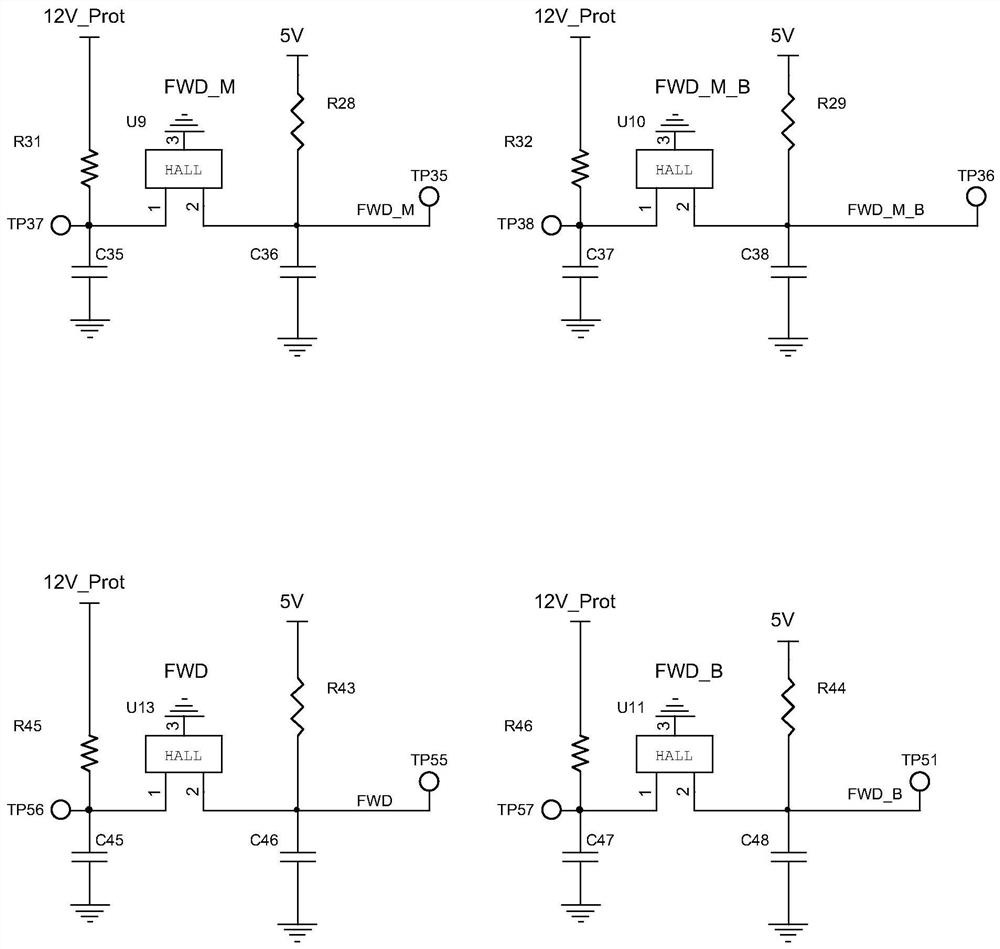

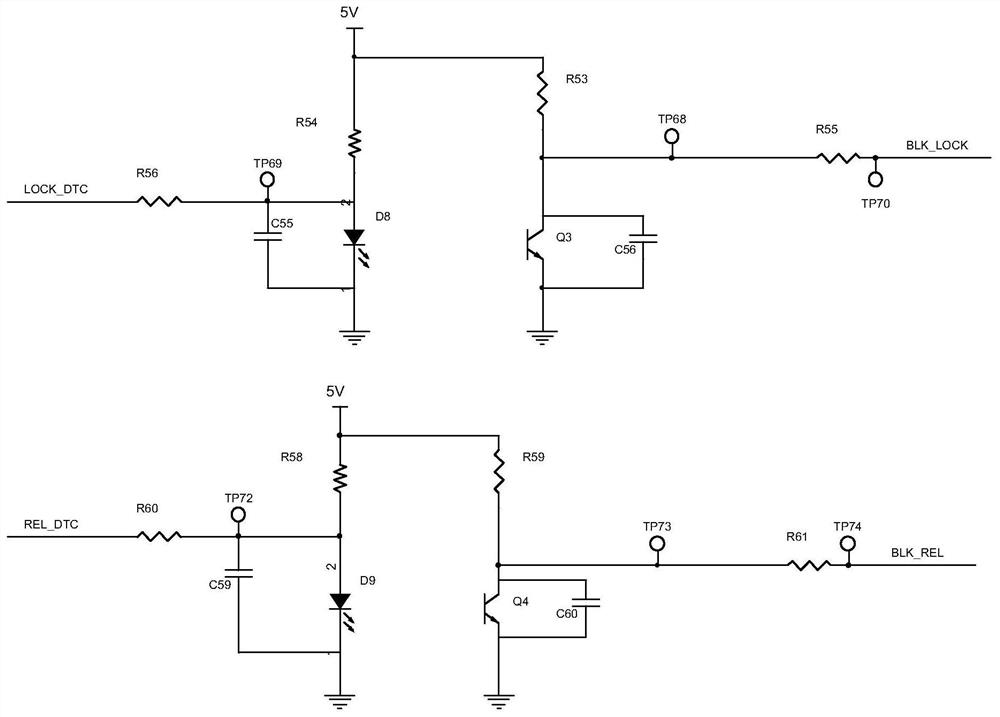

[0061] see attached Figure 1A and Figure 1B , respectively showing a partial circuit structure of the gear sensor of the present invention; figure 2 Shows the circuit structure of the unlocking and locking module of the present invention; image 3 Shows the circuit structure of the main connector of the present invention; Figure 4 Shows the circuit structure of the start switch interface of the present invention; Figure 5A and Figure 5B Partial circuit structures of the power management module of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com