Compressing mechanism and compressor with same

A compression mechanism and a rotary compressor technology, applied in the field of compressors, can solve the problems of poor applicability and reliability of the exhaust valve plate, difficulty in designing the stiffness of the exhaust valve plate, and limited design flexibility, so as to improve design flexibility performance and applicability, improve the timeliness and reliability of closing, and improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

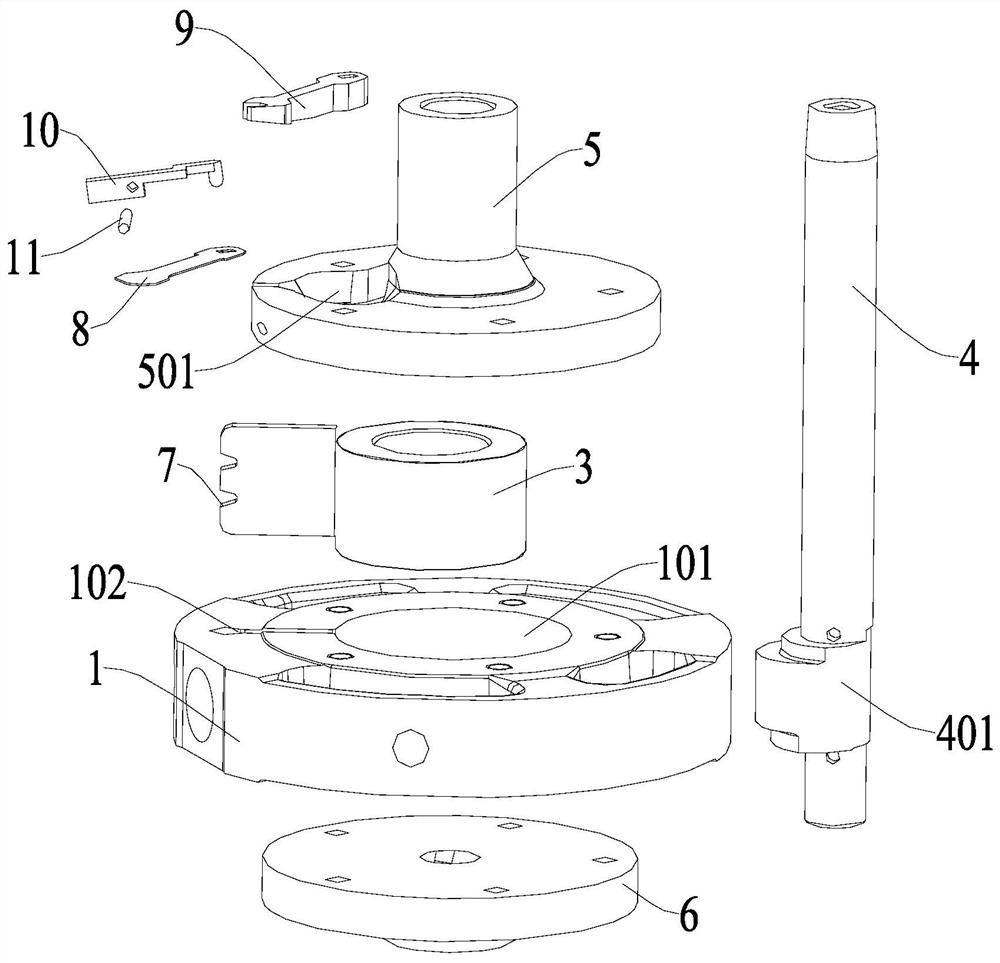

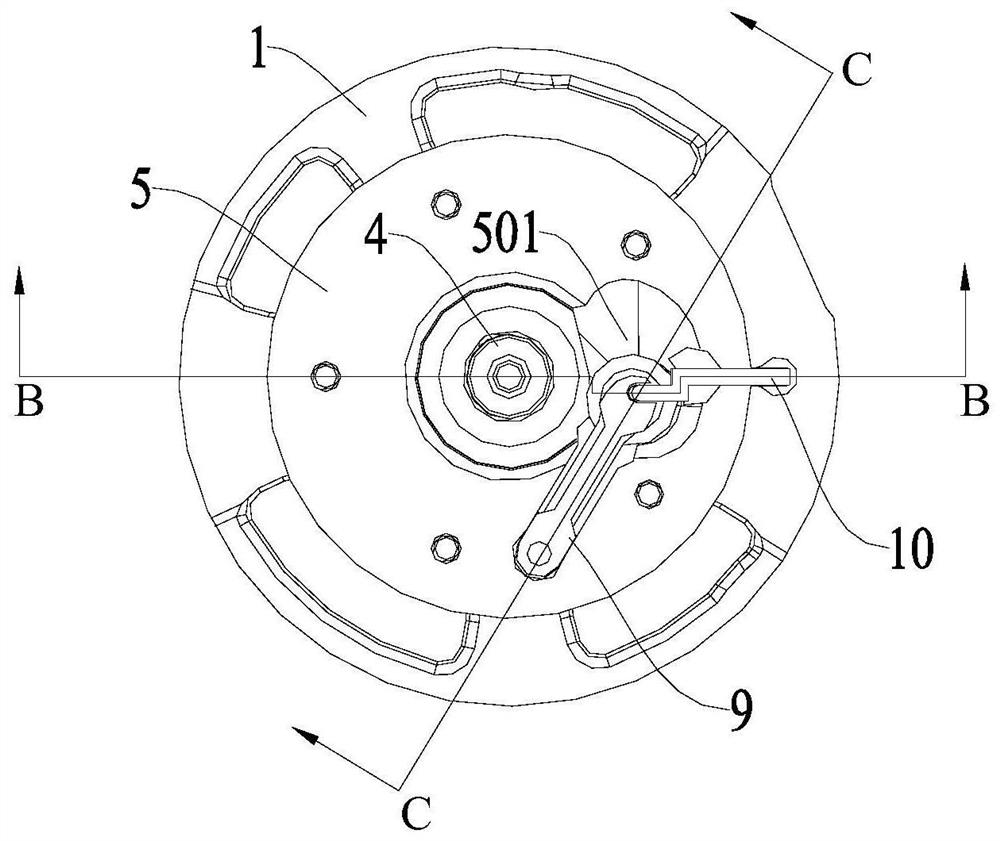

[0066] Refer below Figures 1 to 18 A compression mechanism 300 and a rotary compressor according to an embodiment of the present invention are described.

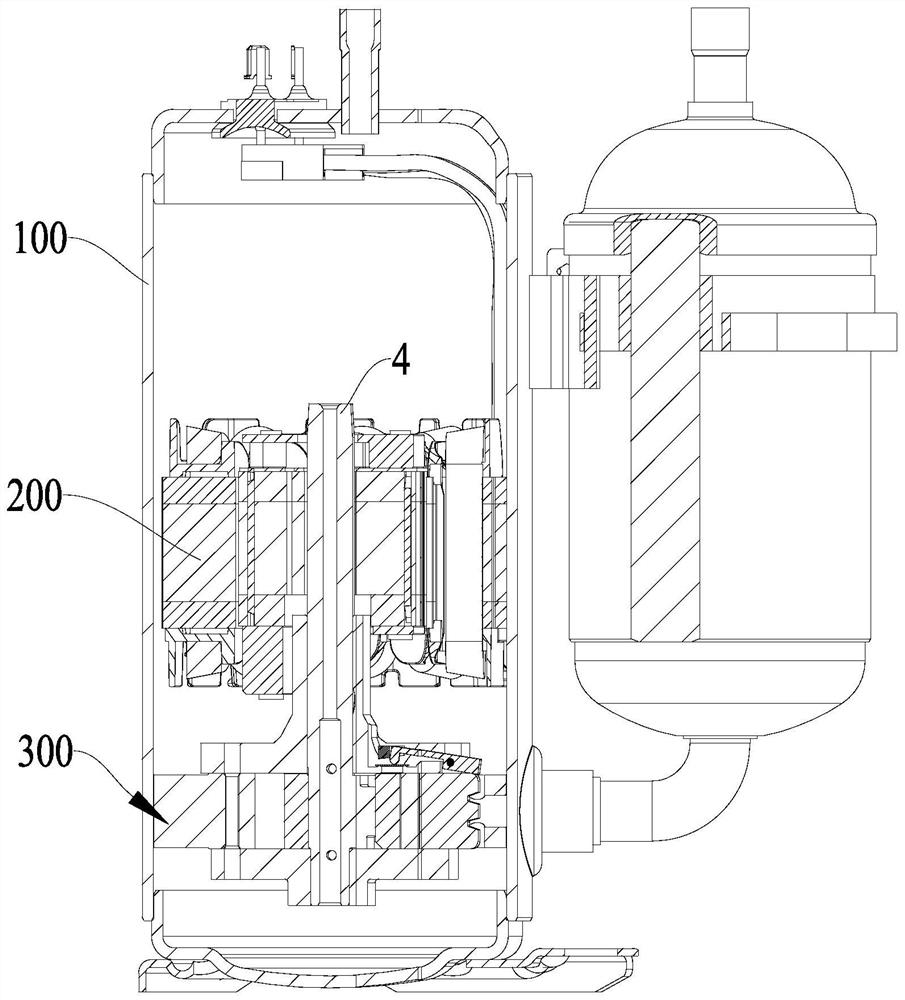

[0067] Such as figure 1 As shown, the rotary compressor according to the embodiment of the present invention includes a housing 100 , a motor 200 and a compression mechanism 300 , the motor 200 and the compression mechanism 300 are installed in the housing 100 , and the motor 200 is used to drive the compression mechanism 300 .

[0068] The compression mechanism 300 of the rotary compressor according to the embodiment of the present invention will be described in detail below with reference to the accompany...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com