Discharging and stirring system of vertical pyrolyzing furnace

A stirring system and pyrolysis furnace technology are applied in the field of vertical pyrolysis furnace discharge stirring system, which can solve the problems of pyrolysis furnace slagging, loose distribution of small-density raw materials, pyrolysis furnace discharge, and uneven pyrolysis. , to achieve the effect of preventing furnace slagging, timely discharging, and preventing loose distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

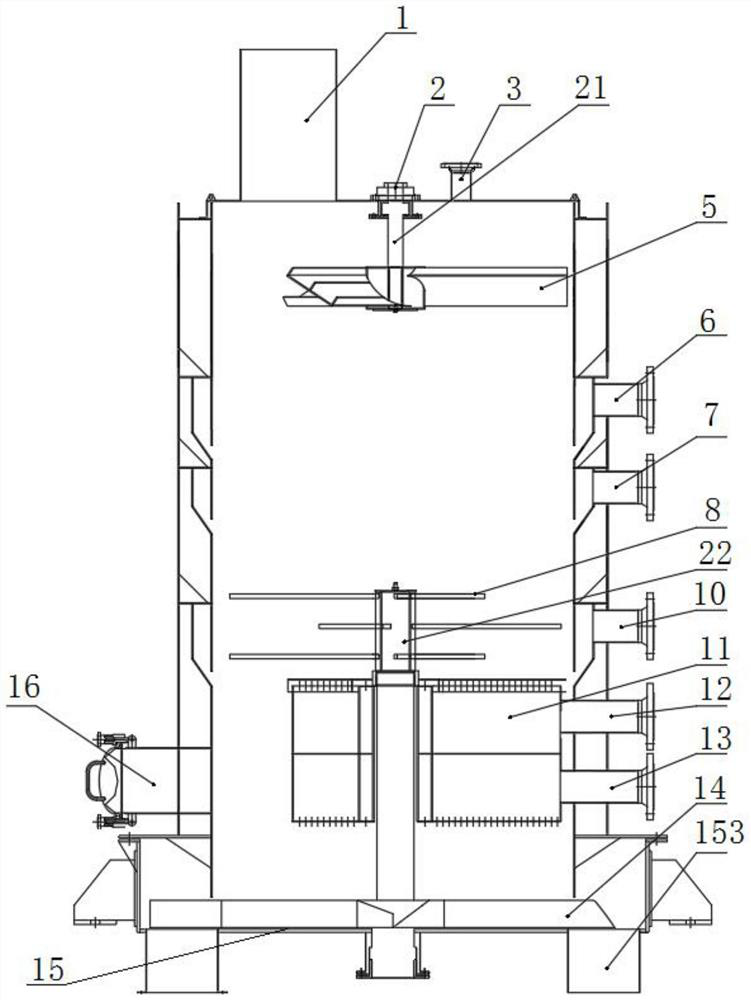

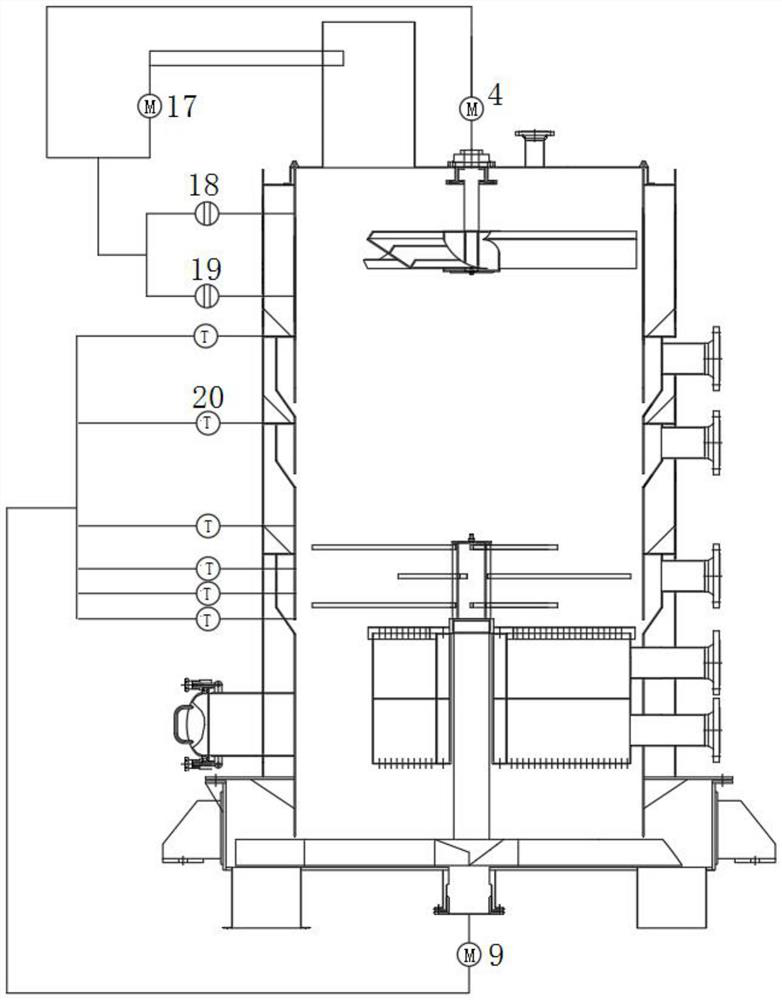

[0032] Such as figure 1 As shown, this embodiment provides a novel vertical pyrolysis furnace compaction, stirring and discharging system, including a compacting mechanism 5, a stirring mechanism 8 and a discharging mechanism 14 arranged in the furnace body from top to bottom. The structure of each institution is as follows;

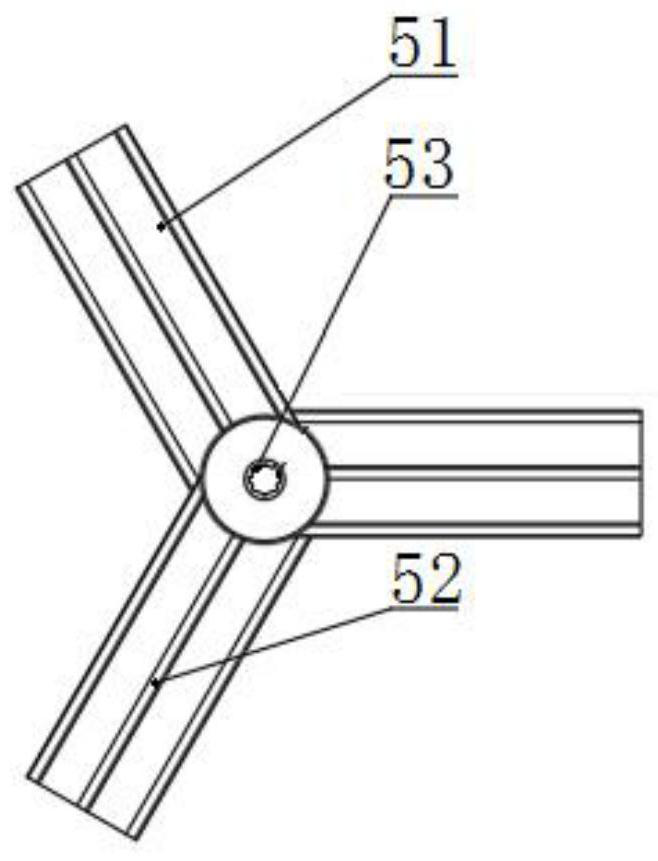

[0033] Such as image 3 As shown, the compacting mechanism 5 is mainly composed of a compacting plate 51 , a spline 1 53 and a reinforcing rib 52 . The compacting plate 51 is circumferentially installed on the spline one 53, and the compacting plate 51 has a certain angle with the horizontal plane. The compacting plate 51 is fixed on the bottom end of the rotating shaft one 21 by the spline one 53, and the top end of the rotating shaft one 21 It is connected with motor one 4, and a bearing 2 is installed between the rotating shaft one and the furnace body. When the motor one 4 rotates clockwise, the compacting plate 51 has a compacting and leveling ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com