Automatic rodlike packaging device

A rod-shaped, automatic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of leakage of contents, limited increase in production efficiency, weak adhesion of lateral bonding surfaces, etc. The effect of shortening the heat fusion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, preferred embodiments of the method according to the present invention will be described with reference to the accompanying drawings. In the process, for clarity and convenience of description, the thickness of lines or the size of structural elements in the drawings may be shown in an enlarged manner. In addition, the terms described later are terms defined in consideration of their functions in the present invention, and may be changed according to user's or operator's intention or custom. Therefore, the terms as above should be defined based on the entire content in this specification.

[0048] refer to figure 1 to explain.

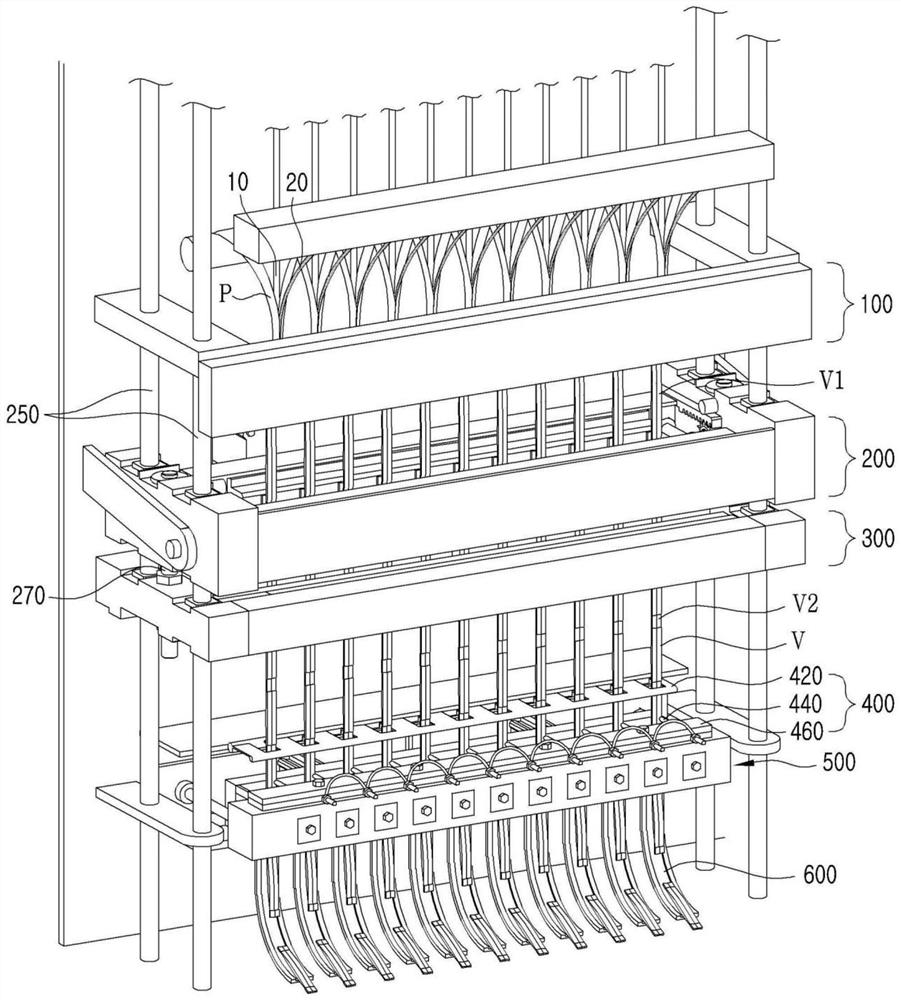

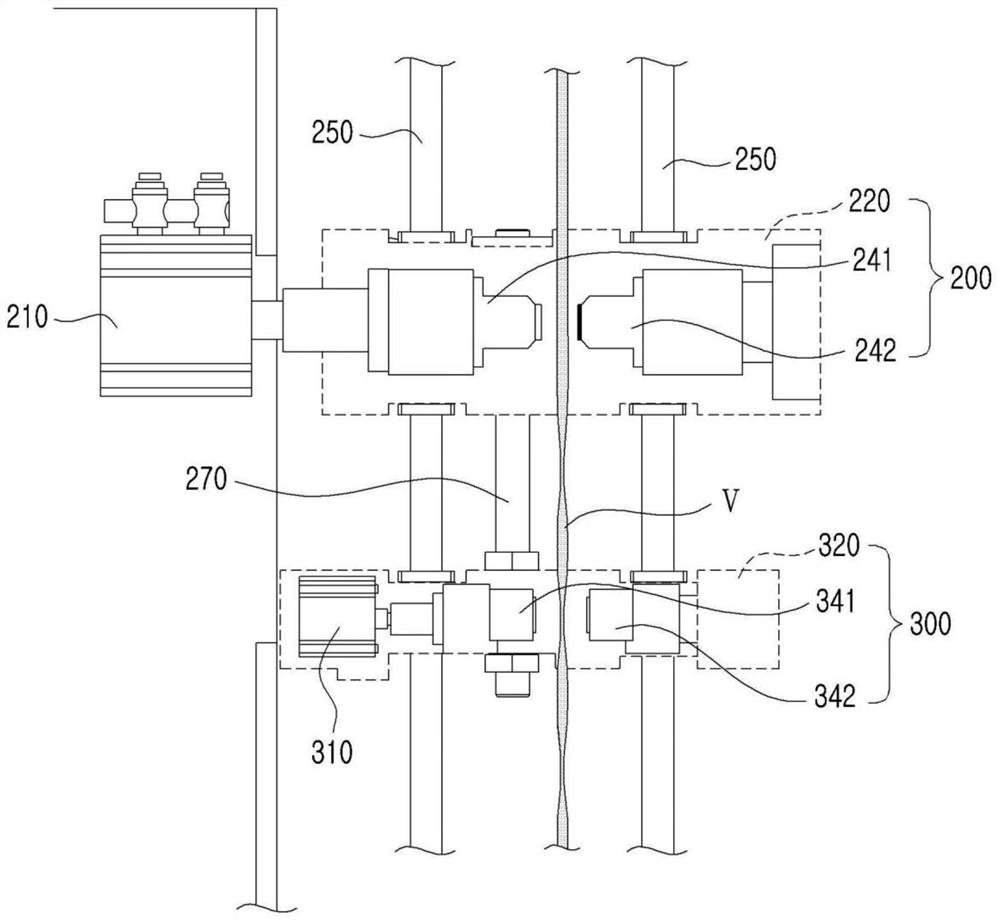

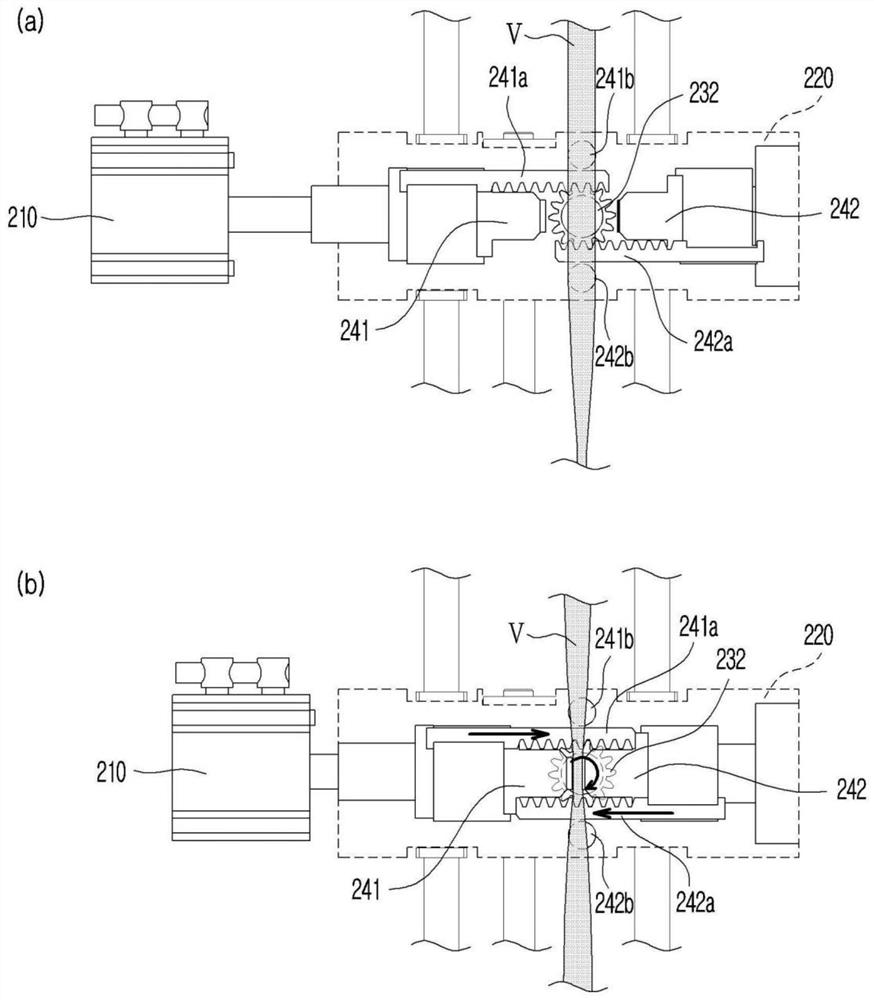

[0049] The automatic stick packaging device according to the present invention includes a first thermal fusion unit 100 , a second thermal fusion unit 200 , an auxiliary pressing unit 300 , a capacity sensing unit 400 and a cutting unit 500 .

[0050] The wrapping paper P surrounds the supply tube 10 in a tube form, and is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com