Conveying device for mask conveying production

A technology for transporting devices and masks, which is applied in the field of transporting devices for mask transmission and production, and can solve problems such as easily damaged mask structures and unfavorable mask packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

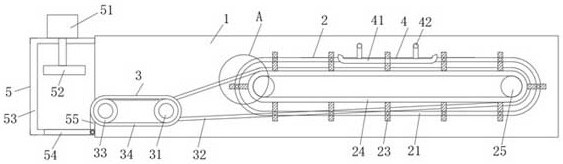

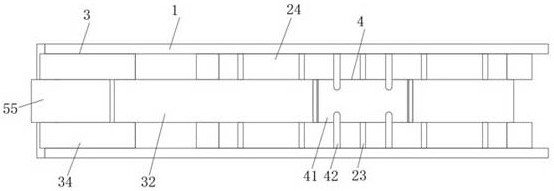

[0027] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: a transportation device for mask transmission production, including a fixed plate 1, two fixed plates 1 are provided, and a transmission mechanism 2, a lower Material mechanism 3, flattening structure 4 and pressing structure 5, described transmission mechanism 2 comprises No. The divider plates 23 are all fixedly connected on the outer side wall of the main conveyor belt 24, and a plurality of the divider plates 23 are located on both sides of the main conveyor belt 24, and a plurality of the divider plates 23 are located in the flattening structure 4. The two sides of the No. 1 rotating rod 25 are provided with two, the two ends of the No. 1 rotating rod 25 are connected to the fixed plate 1 in rotation, and the two No. 1 rotating rods 25 are all connected to the main transmission belt 24 for transmission. The drive motor is fixedly connected to the outer wall of one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com