Tire

A technology for tires and crowns, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of low rigidity of pattern blocks and falling blocks, so as to improve snow performance and snow drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, one embodiment of the present invention will be described in detail based on the drawings.

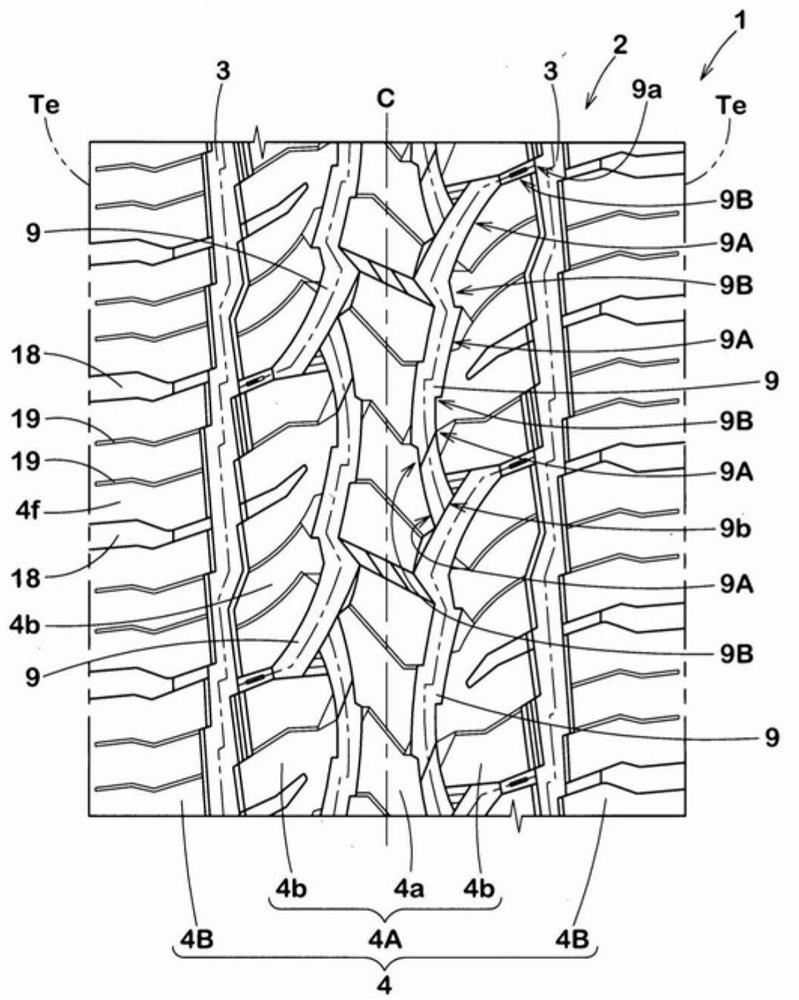

[0024] figure 1 It is a developed view showing the tread portion 2 of the tire 1 of the present embodiment. Such as figure 1 As shown, the tire 1 of the present embodiment is suitable as a pneumatic tire having a tread portion 2 suitable for running on snowy roads.

[0025] The tire 1 may be a pneumatic tire for running on uneven roads such as muddy ground, for example, other than snowy roads. In addition, the tire 1 is not limited to a pneumatic tire, and may be a non-pneumatic tire that does not fill the inside of the tire 1 with pressurized air, for example.

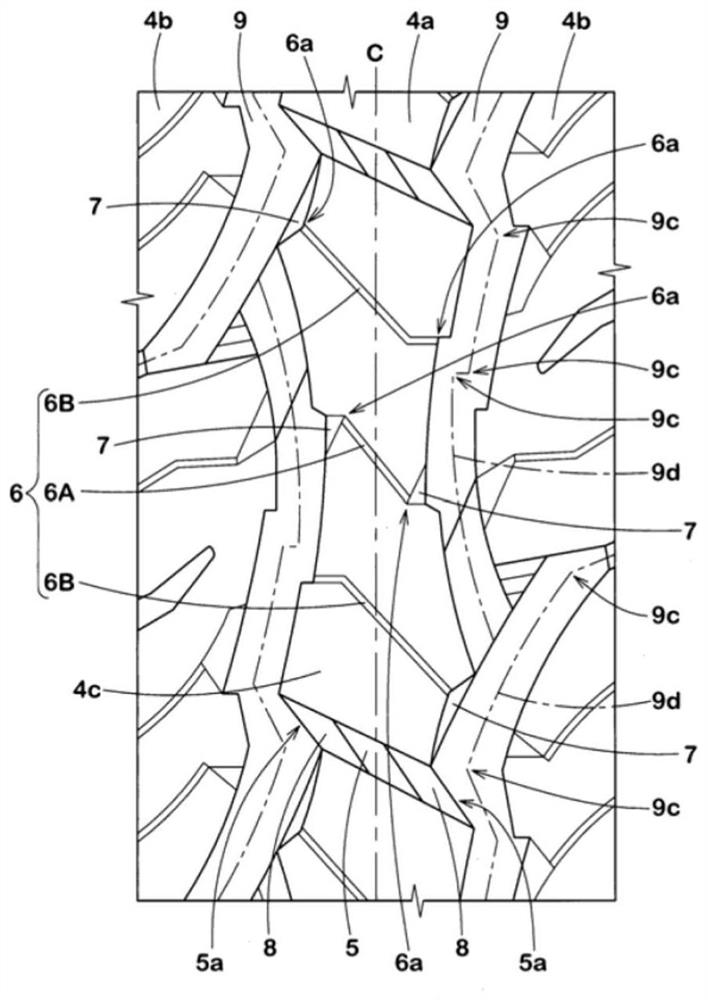

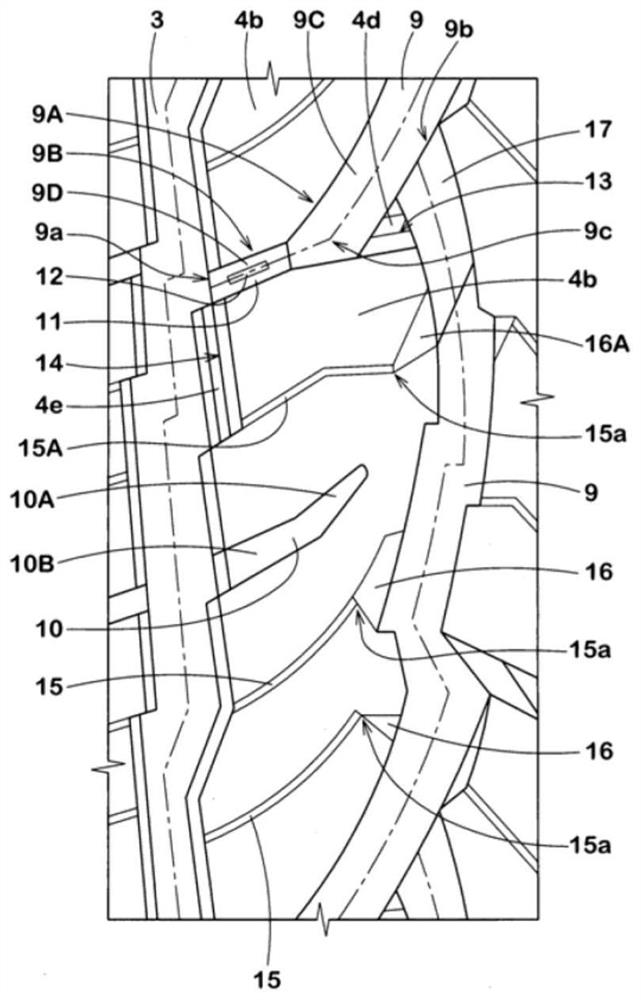

[0026] A plurality of circumferential grooves 3 extending in the tire circumferential direction and a plurality of land portions 4 defined by the circumferential grooves 3 are formed in the tread portion 2 of the present embodiment. For example, one circumferential groove 3 is formed between the tire eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com