Laminating device and method for connecting rod pushing type stepped paper box packaging paper

A laminating device and step-type technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of no process and high cost, and achieve the effect of ensuring flexible and non-destructive contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

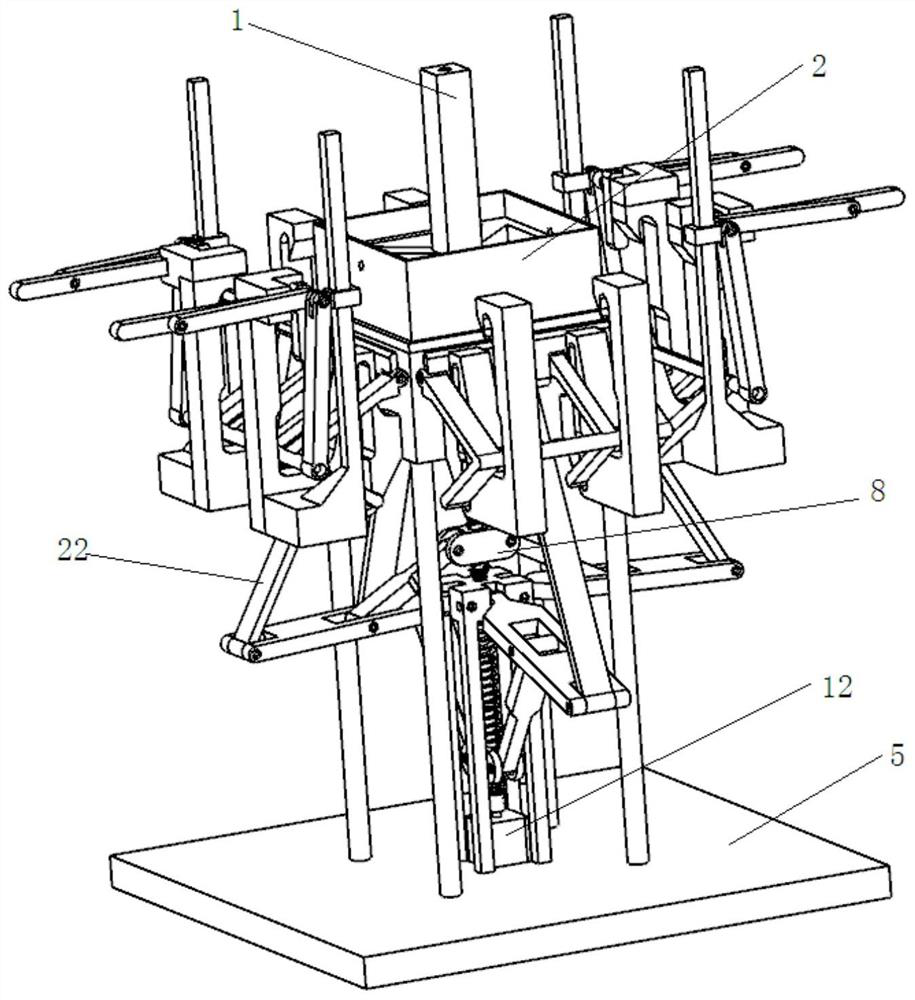

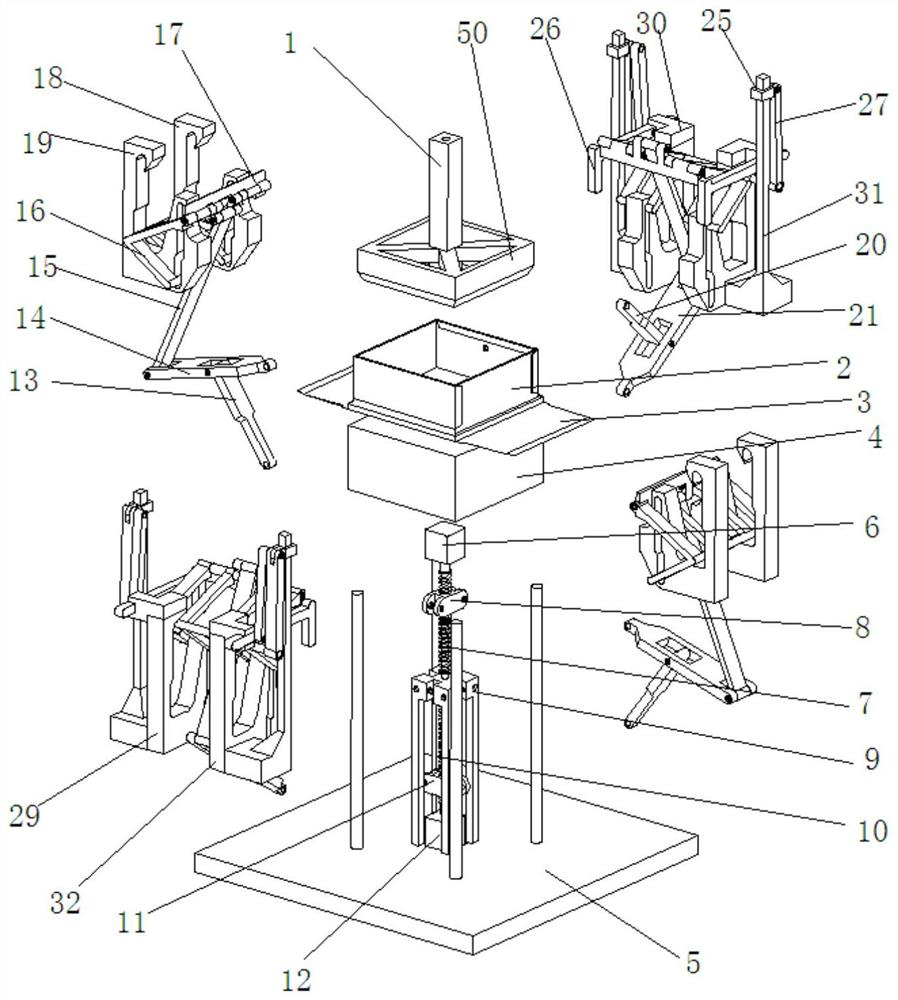

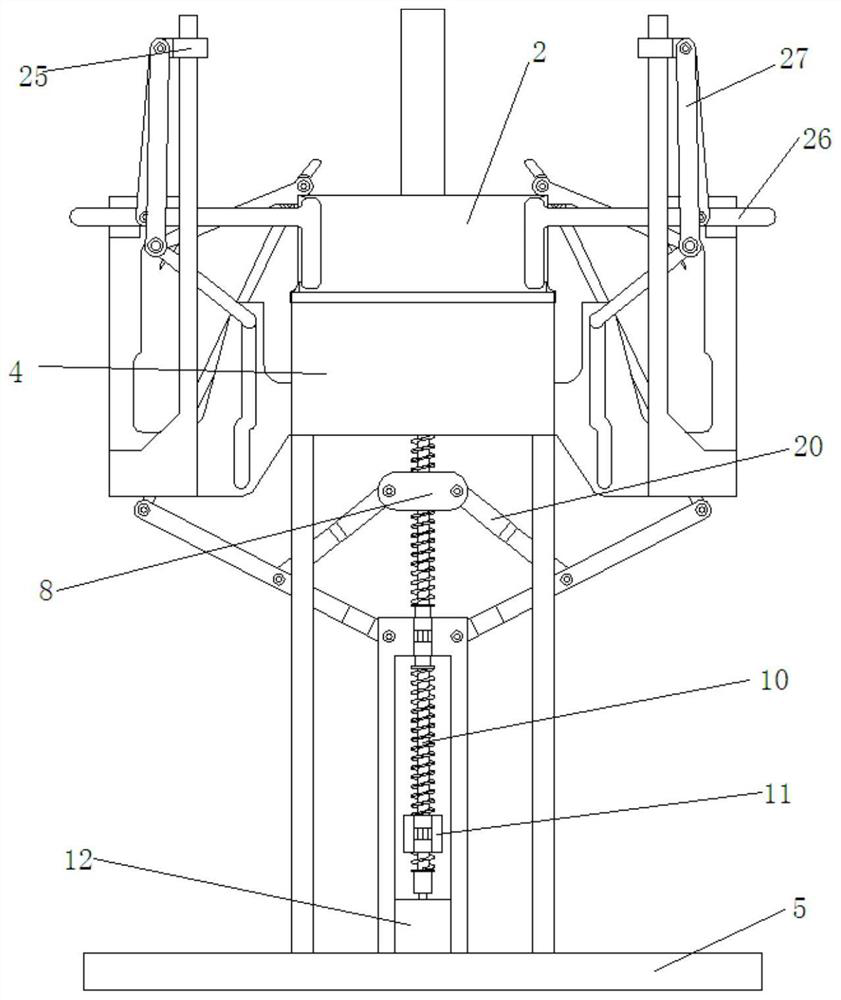

[0041] Such as figure 1 and Figure 13 As shown in the present invention, a connecting rod push type ladder-type carton wrapping paper bonding device of the present invention includes a ladder-type carton 2, and also includes a positioning support assembly, a drive assembly, a narrow-side sticker assembly and a wide-side sticker assembly;

[0042] The positioning support assembly includes a pneumatic column 1, a carton support platform 4, and a base 5. Below the pneumatic column 1, there are four positioning side plates 50 that fit the inner side walls of the stepped carton 2. The bottom of the positioning side plate 50 is Both ends are provided with chamfers, and a vacuum suction cup 51 is installed on the bottom surface of the pneumatic column 1. The vacuum suction cup 51 is adsorbed to the inner surface of the bottom plate of the stepped carton 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com