Control method for polymer modification device

A control method and polymer technology, which is applied in the control field of polymer modification devices, can solve problems such as no system, reaction heat runaway, etc., and achieve the effect of preventing accidents and avoiding unplanned parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

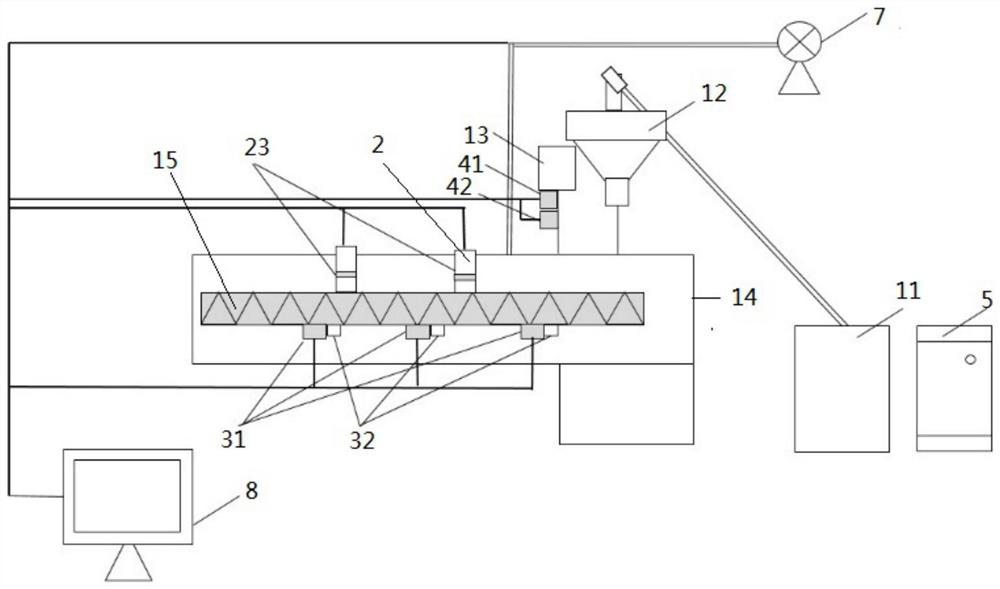

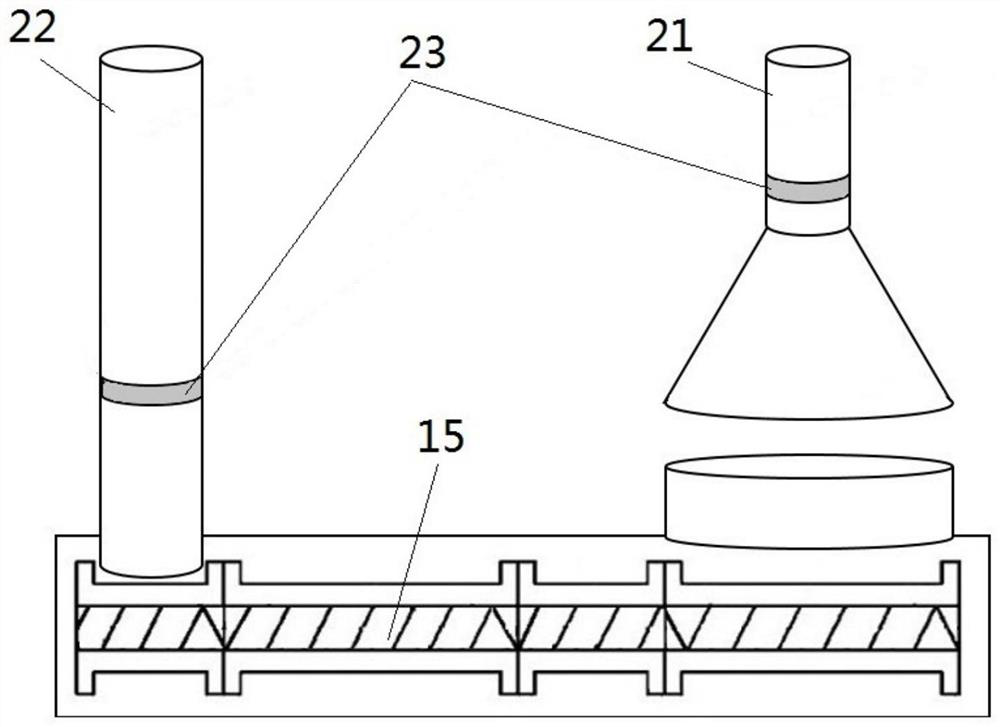

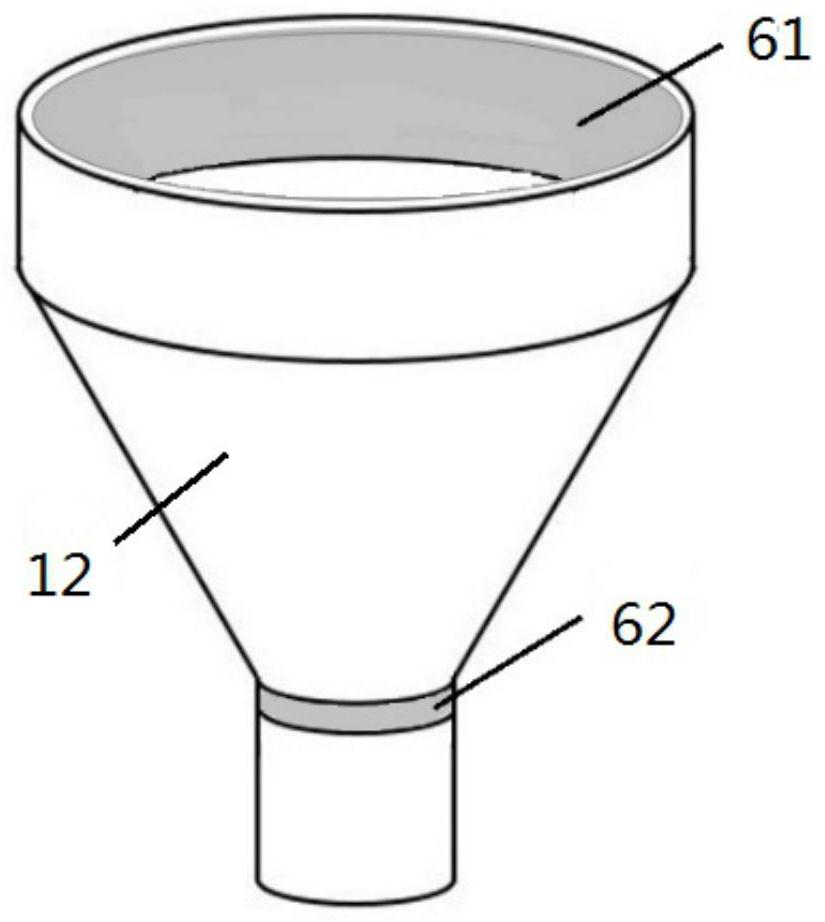

[0072] The polymer modification device includes an extrusion unit, a heating unit, a drive unit, a devolatilization unit, a control unit and an alarm structure. The extrusion unit includes a powder silo 11, a hopper 12, a plasticizer feed tank 13, a barrel 14 and a screw 15, and a flow meter 41 and a flow alarm 42 are arranged on the plasticizer feed tank 13; The heating unit heats the barrel; the drive unit is a motor, and the output shaft of the motor is connected to the screw 15; the devolatilization unit includes an atmospheric devolatilization tube 21 and a vacuum devolatilization tube 22 arranged in sequence along the moving direction of the material, and an atmospheric devolatilization tube 22 connected with the normal pressure devolatilization tube. The induced draft fan 7 connected to the pipe 21 and the vacuum devolatilization pipe 22; the control unit is electrically connected to all the electric control structures of the extruding unit, the heating unit, the driving...

Embodiment 2

[0076] The polymer modification device includes an extrusion unit, a heating unit, a driving unit, a devolatilization unit, a control unit and an alarm structure. The extrusion unit includes a powder silo 11, a hopper 12, a plasticizer feed tank 13, a barrel 14 and a screw 15, and inside the barrel 14, a plurality of temperature detectors 31 and The temperature alarm 32; the heating unit heats the barrel; the drive unit is a motor, and the output shaft of the motor is connected to the screw rod 15; the devolatilization unit includes an atmospheric devolatilization tube 21 and a vacuum devolatilization tube 22 arranged in sequence along the moving direction of the material; The induced draft fan 7 connected with the atmospheric pressure devolatilization pipe 21 and the vacuum devolatilization pipe 22; the control unit is connected with all the electric control structures of the extrusion unit, the heating unit, the drive unit, the devolatilization unit and a plurality of tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com