Multifunctional automatic injection mold

An injection mold and multi-functional technology, applied in the field of multi-functional automatic injection molds, can solve the problems of warping deformation of plastic parts, post-crystallization, large mold temperature difference, etc., to reduce production and production costs, simplify device structure, and simple structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

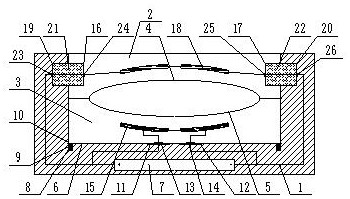

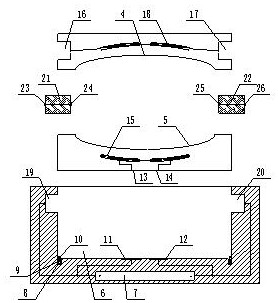

[0035] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 shown;

[0036] The inventive point of the present application is that an installation groove 6 is provided on the table surface of the workbench, and the installation groove communicates with the front and rear surfaces of the workbench, and baffles are arranged at the front and rear ports of the installation groove, and the height of the baffle does not exceed the height of the lower mold. The shape and size of the upper mold and the lower mold are matched with the installation groove, the upper mold and the lower mold are located in the installation groove, the lower mold is located on the bottom surface of the installation groove, and the upper mold is buckled on the lower mold , a battery 7 is installed in the workbench,

[0037] The inventive point of the present application is that several grooves 8 are arranged on the bottom surface of the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com