Foaming body with heating device and producing process of foaming body

A heating device and manufacturing process technology, which is applied to seat heating/ventilation devices, other household appliances, household components, etc., can solve problems such as installation conflicts in the bonding method, and can achieve the function of occupant detection and protection circuits. , to avoid the effect of heating function failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the implementation of the present invention will be further described below in conjunction with specific illustrations.

[0069] A manufacturing process of a foam with a heating device, comprising the following steps:

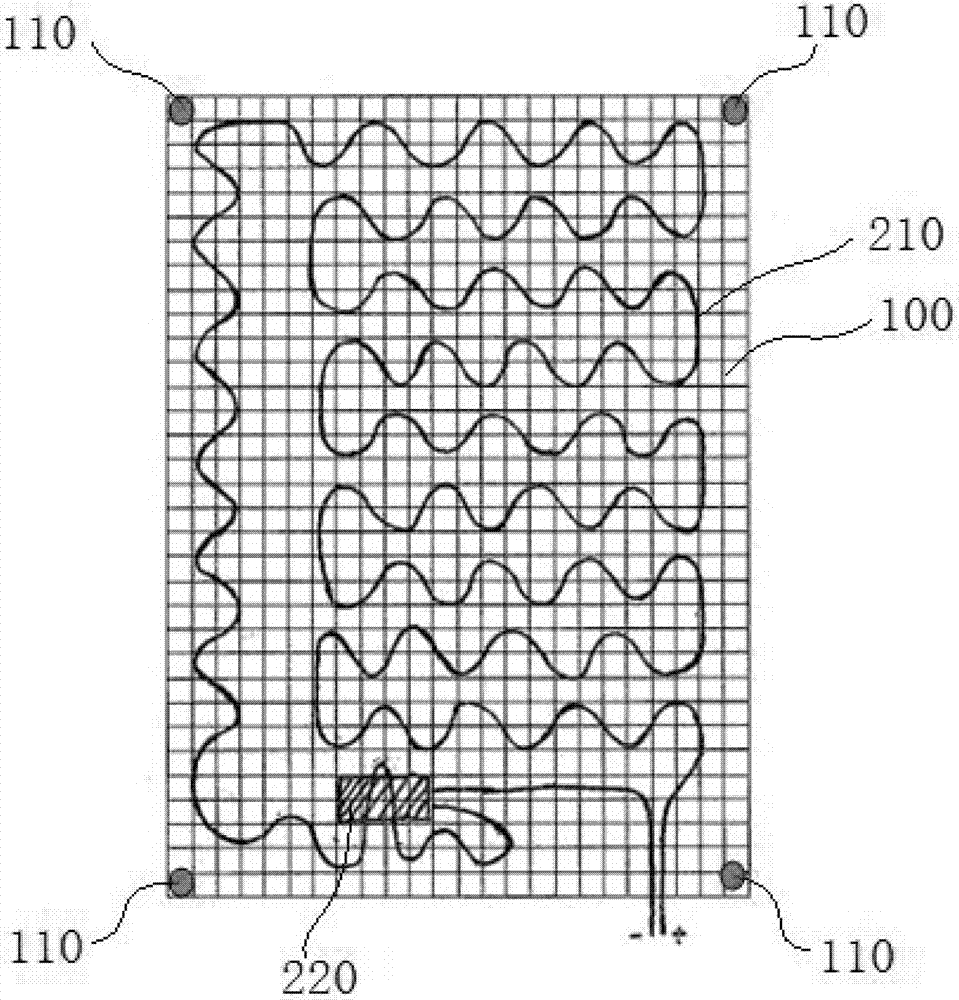

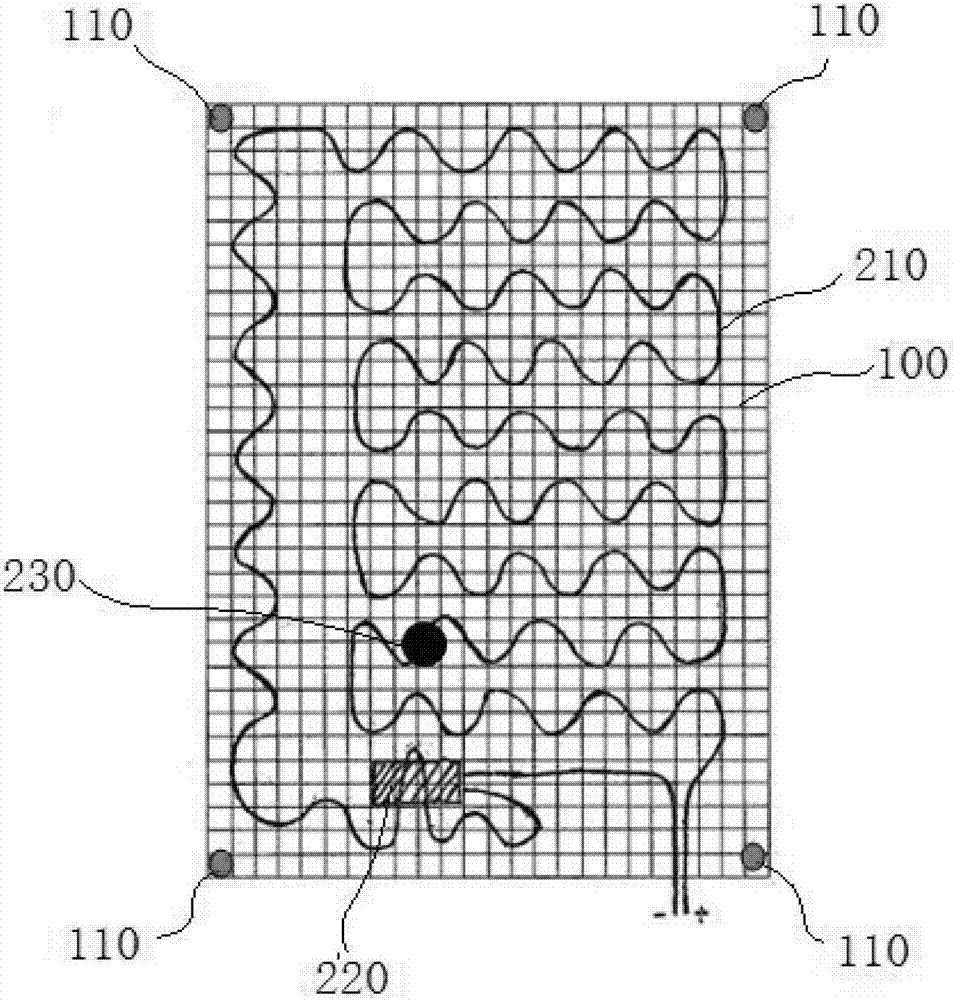

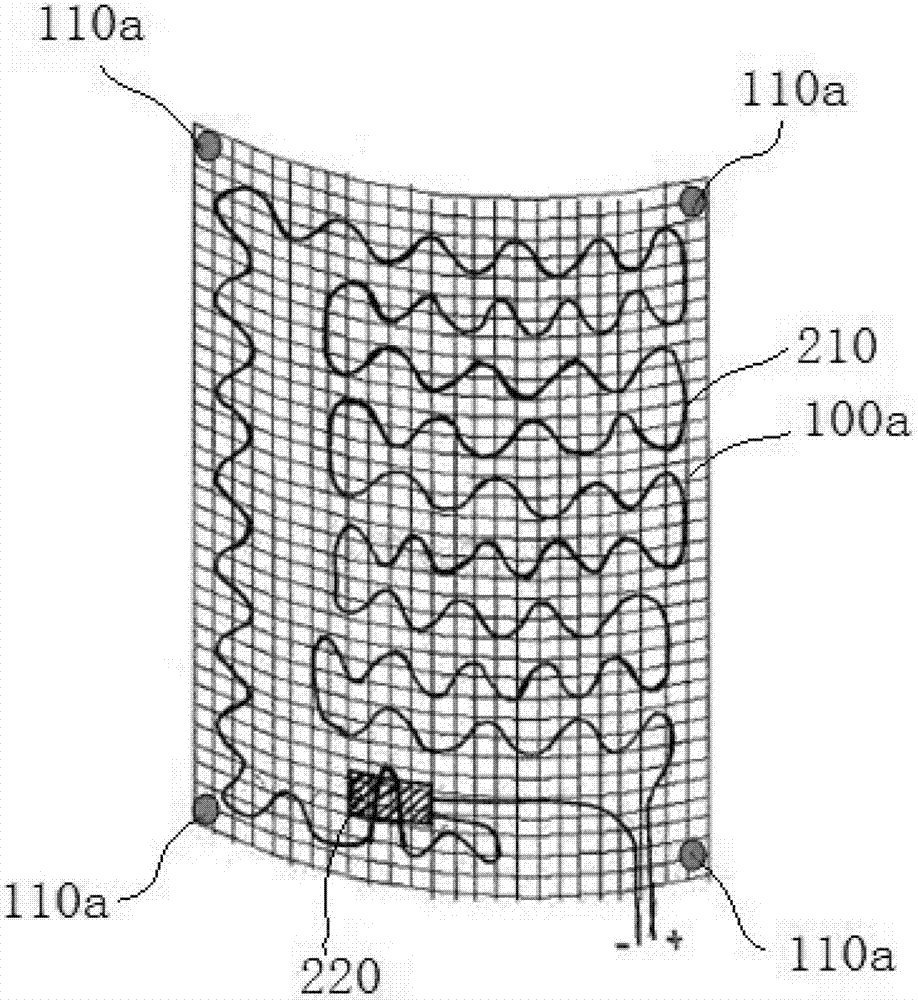

[0070] (1), see Figure 1 to Figure 4 , prepare the mesh-like transparent base layer 100, the mesh-like transparent base layer 100 is made of mesh-like transparent material, the mesh-like transparent material is such as glass fiber mesh cloth, multi-void interval braided fabric, porous knitted cloth, porous non-woven fabric , Multi-gap spacer braids and other materials. Mesh cloth needs high temperature resistance, liquid resistance, high strength, and fire insulation at the same time. The multi-gap spacer braid is a woven net made of nylon and other materials.

[0071] The mesh size of the transparent base layer 100 is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com