An Integral Type Frame for Riveting and Assembling Non-Circular Section Parts

A non-circular cross-section, integrated technology, applied in the field of mechanical processing, can solve the problems of parts deformation, dimensional accuracy and overall shape accuracy that cannot meet the design requirements, and cannot perform precise positioning, etc., to achieve simple operation, simple part structure, and convenient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

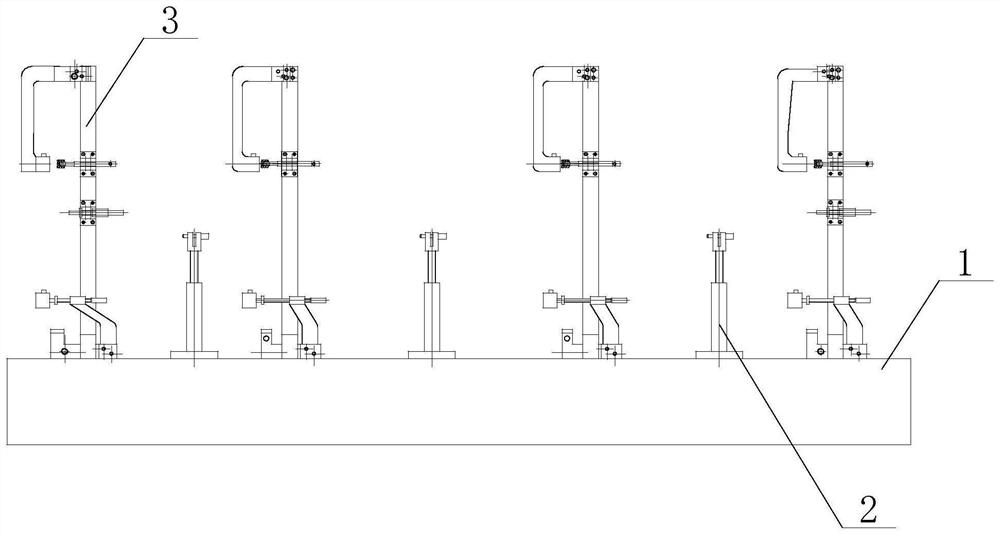

[0020] Specific implementation mode one: combine figure 1 Describe this embodiment. The integral type frame for riveting and assembling non-circular cross-section parts described in this embodiment includes a platform 1, three clamping mechanisms 2 and four frame structures 3, and the four frame structures are installed vertically side by side on the On the upper surface of the platform 1, a clamping mechanism 2 is provided between two adjacent frame structures 3.

specific Embodiment approach 2

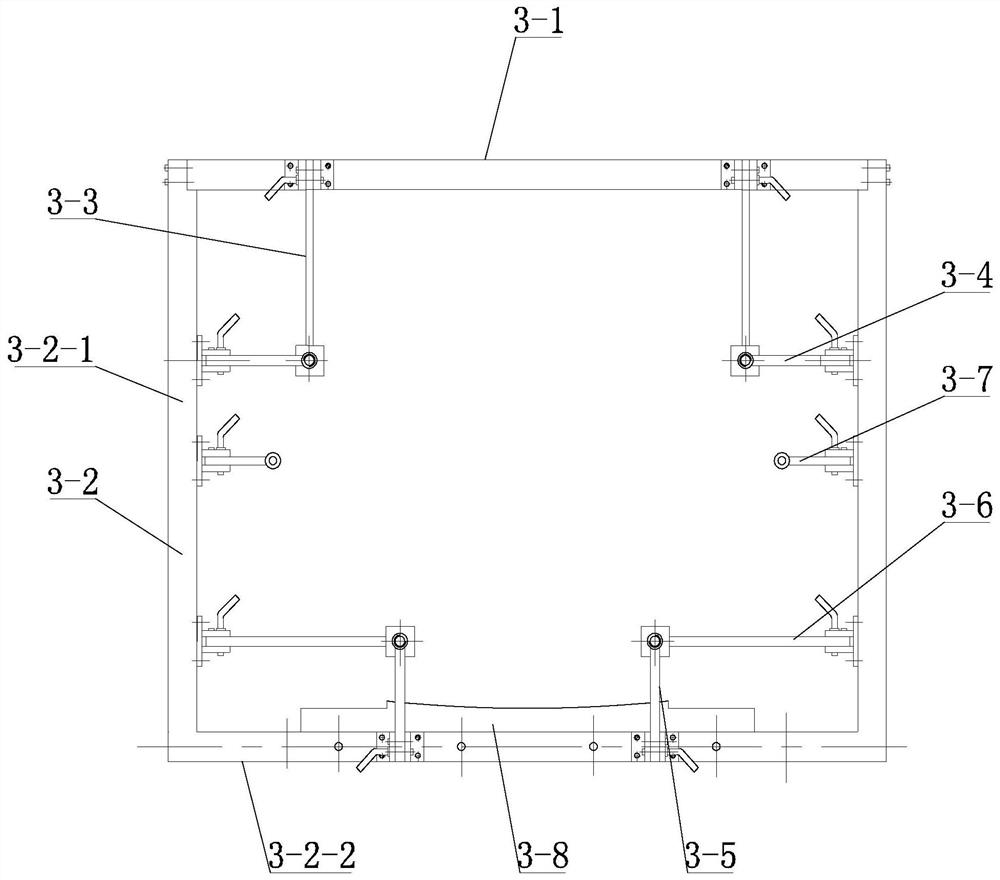

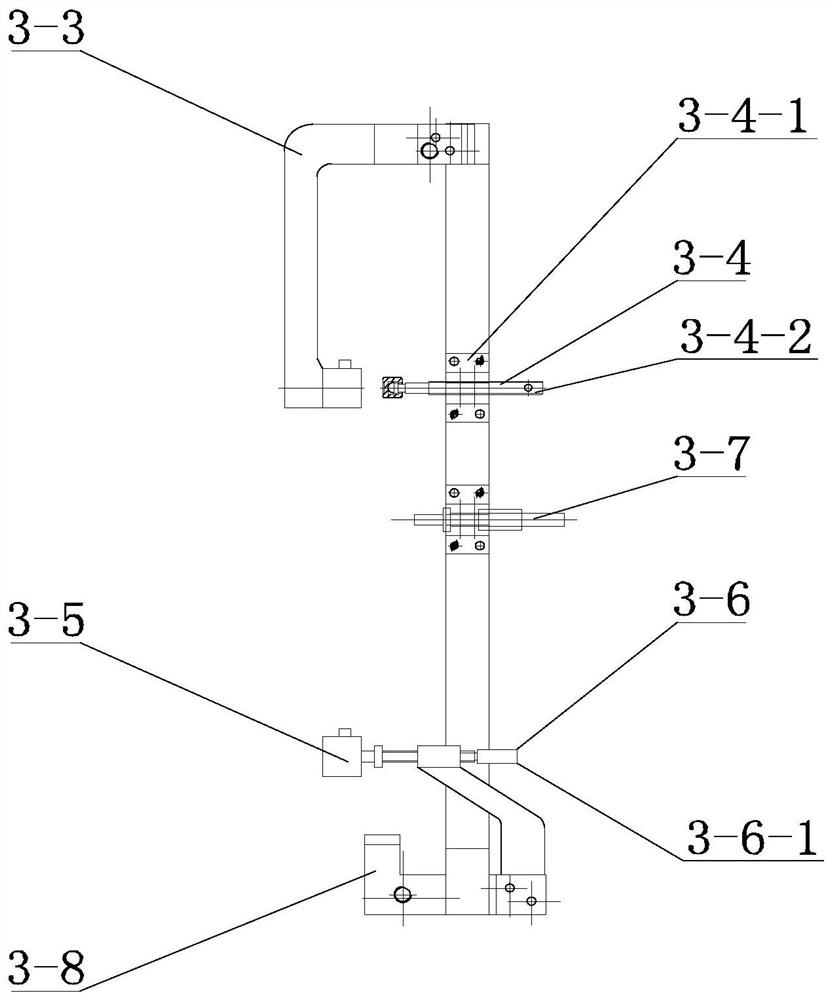

[0021] Specific implementation mode two: combination figure 2 with image 3 Describe this embodiment, a frame structure 3 for riveting and assembling non-circular cross-section integral type frames described in this embodiment includes an upper beam 3-1, a U-shaped frame 3-2, and two upper beam retaining assemblies 3 -3. Two upper beam locking components 3-4, two lower beam retaining components 3-5, two lower beam locking components 3-6, two positioning pins 3-7 and bottom bracket 3-8 , the two ends of the upper beam 3-1 are connected with the upper ends of the two legs 3-2-1 of the U-shaped frame 3-2, the upper beam 3-1 and the U-shaped frame 3-2 form a rectangular frame, two The upper beam retaining assembly 3-3 is installed side by side on the upper beam 3-1 along the length direction of the upper beam 3-1, and the inner surface of each leg 3-2-1 of the U-shaped frame 3-2 is from top to bottom Install an upper beam locking assembly 3-4, a positioning pin 3-7, a lower bea...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 4 with Figure 5 This embodiment is described. An upper beam retaining assembly 3-3 for riveting and assembling non-circular cross-section integral type frames described in this embodiment includes an upper beam vertical plate 3-3-1, a first connecting pin 3- 3-2, the first ear seat 3-3-3, the first bent handle positioning pin 3-3-4, the first square positioning block 3-3-5 and the first set screw 3-3-6, The upper beam vertical plate 3-3-1 is an L-shaped plate body, and one end of the upper beam vertical plate 3-3-1 is connected with the first lug seat 3-3-3 through the first connecting pin 3-3-2, and the second An ear seat 3-3-3 is connected with the upper beam 3-1, the first bent handle positioning pin 3-3-4 is installed on the first ear seat 3-3-3, and the first square positioning block 3- 3-5 is installed on the other end of the upper beam vertical plate 3-3-1 through the first set screw 3-3-6.

[0025] Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com