An integrated equipment for processing complex-shaped high-current contact brackets

A complex shape, high current technology, applied in the direction of metal processing equipment, welding equipment, gas flame welding equipment, etc., can solve the problems of affecting efficiency, reducing work efficiency, and affecting efficiency, so as to improve production efficiency, high work efficiency, and operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

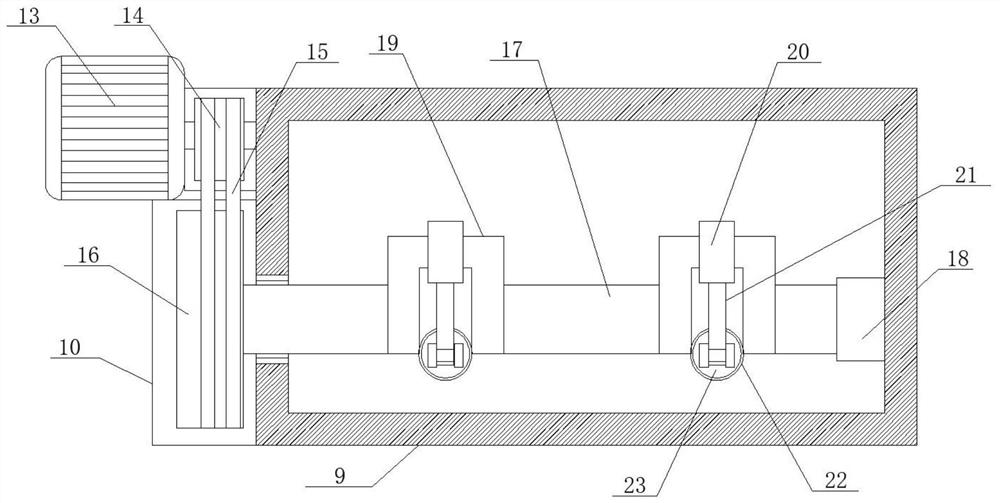

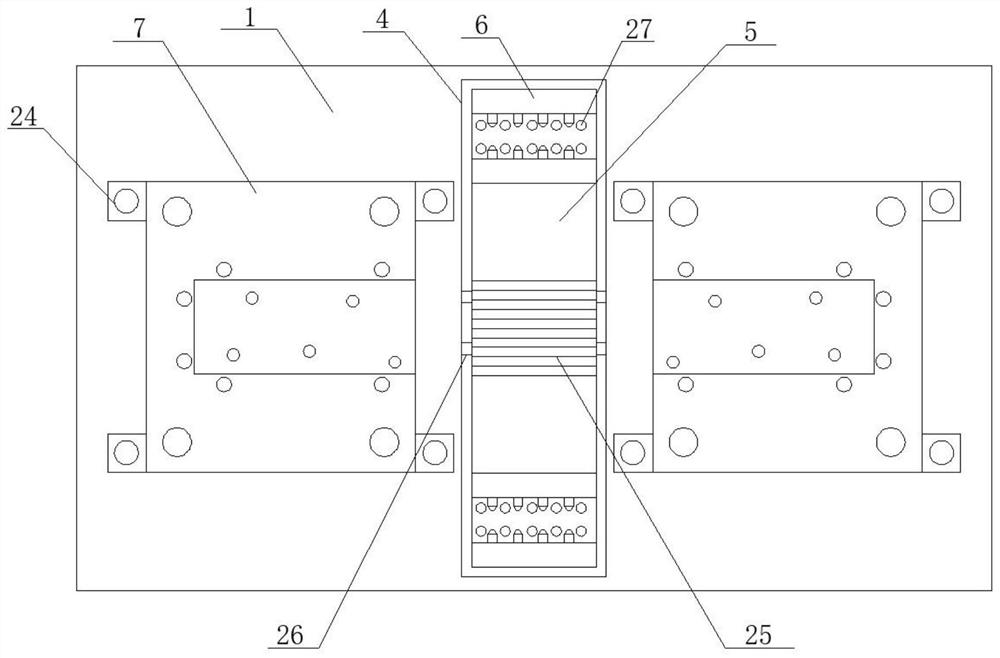

[0031] see figure 1 , in an embodiment of the present invention, an integrated equipment for processing a complex-shaped high-current contact bracket, including a support bottom box 1, the bottom surface of the support bottom box 1 is fixedly welded with a support pad 2, and one side of the support bottom box 1 is welded obliquely There is a control panel 3, the top surface of the support bottom box 1 is longitudinally provided with a flip card slot 4, the number of support pads 2 is several, and a plurality of support pads 2 are fixedly welded on the bottom surface of the support bottom box 1 near the edge , the flip card slot 4 is set longitudinally at the center of the top surface of the support bottom box 1, and the top open end of the flip card slot 4 is set upward, and the bottom end of the flip card slot 4 extends vertically downward to the inner side of the support bottom box 1 In the side position, the inner side of the flip card slot 4 is horizontally connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com