Stainless steel connecting pipe forming machine with automatic feeding and discharging function

An automatic loading and unloading, stainless steel technology, applied in the direction of feeding devices, manufacturing tools, energy industries, etc., can solve the problems of reducing the forming efficiency of stainless steel pipes, unable to load and unload at the same time, unfavorable to assembly line production, etc., to reduce the failure rate, Improve reliability and avoid the effect of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

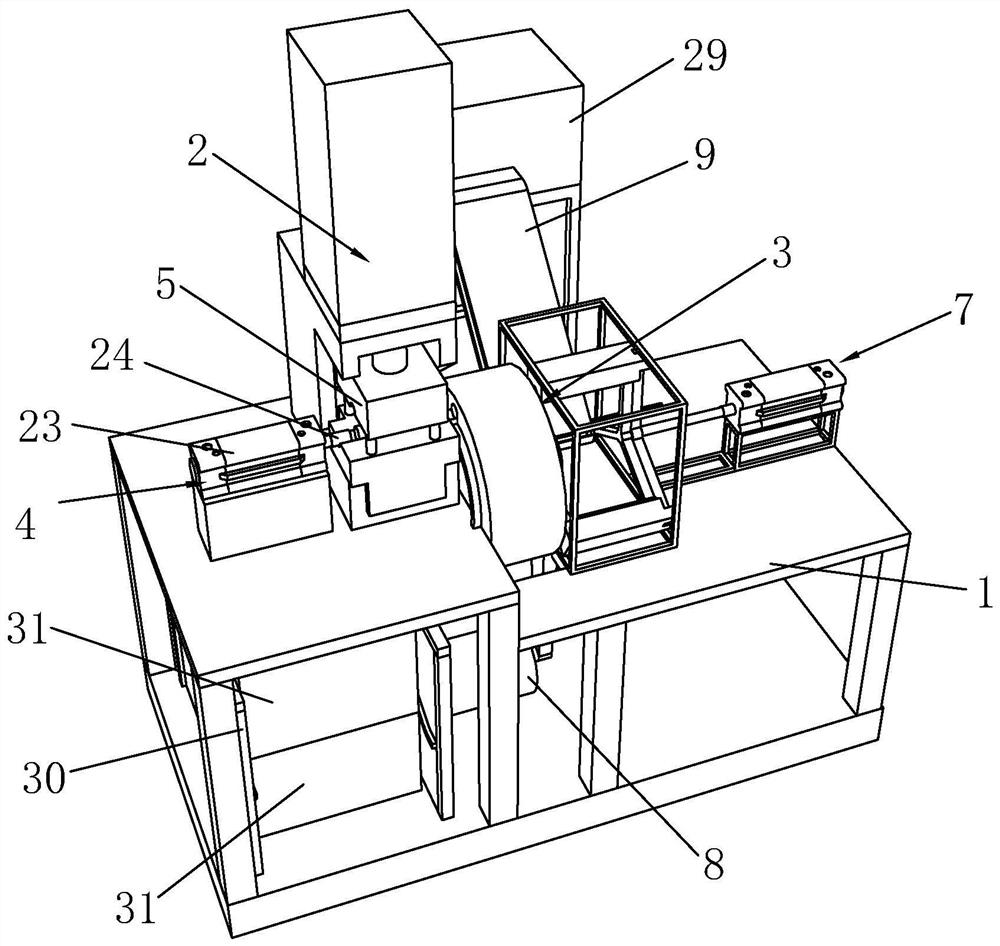

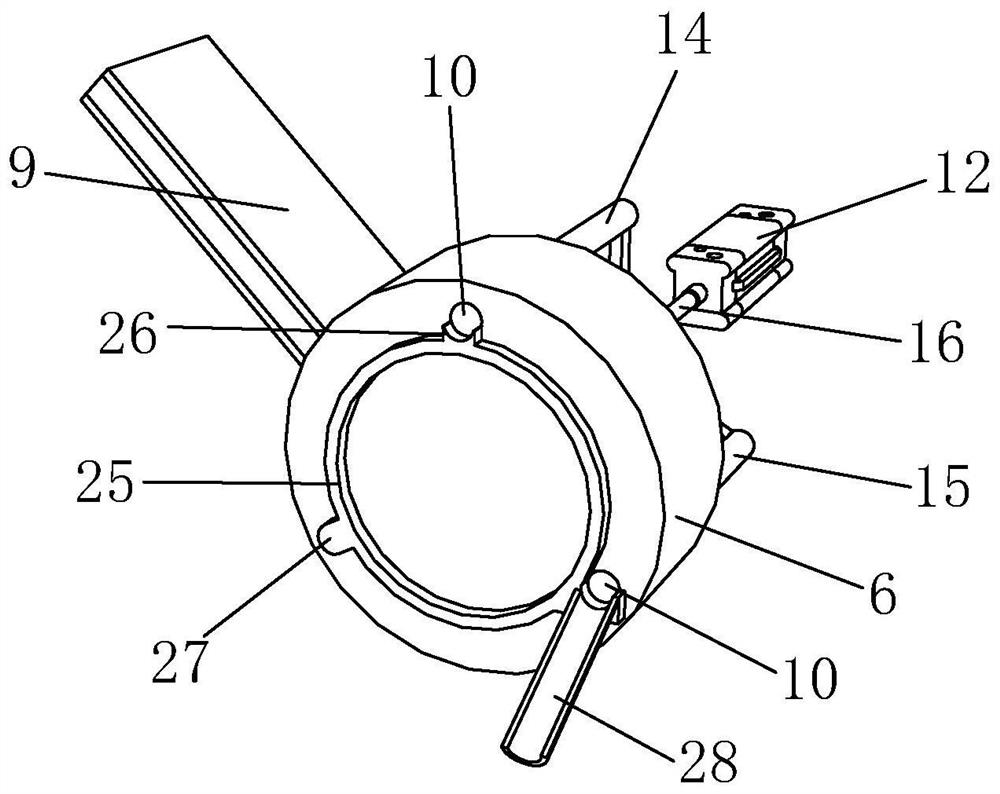

[0027] Such as Figure 1 to Figure 8As shown, it is an automatic loading and unloading stainless steel pipe forming machine of the present invention, including a fixed frame 1, a forming mechanism 2, a loading and unloading mechanism 3, and a material return mechanism 4. The forming mechanism 2 is arranged on the fixed frame 1, and the forming mechanism 2 A mold 5 is provided, and the loading and unloading mechanism 3 and the unloading mechanism 4 are arranged on both sides of the forming mechanism 2 respectively. It is rotatably connected with the fixed frame 1, the drive motor 8 is connected with the feed tray 6, and the drive motor 8 drives the feed tray 6 to rotate. The stainless steel connecting pipe is ejected from the feed tank 10. The loading and unloading mechanism 3 can complete loading and unloading at the same time in one action, which greatly facilitates the assembly line forming production of stainless steel pipes. The combination of the forming mechanism 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com